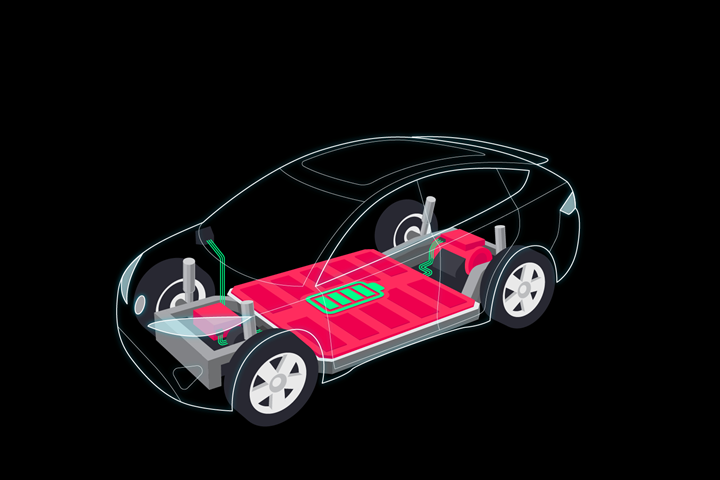

Kordsa supplies carbon fiber fabric for TRB EV battery enclosure production

Kordsa’s supply of carbon fiber fabric offers additional electric vehicle lightweighting opportunities for TRB Lightweight Structures.

Photo Credit: Kordsa

Kordsa (Izmut, Turkey) has recently secured an agreement with TRB Lightweight Structures (Huntingdon, U.K.), a global high-volume composites manufacturing company, to supply carbon fiber fabrics for TRB’s mass production of composite battery enclosures for electric vehicles (EVs) (see CW’s coverage of TRB’s CFRP electric vehicle battery enclosure design).

The project was initiated at TRB facilities in the U.K., and will continue at the company's U.S. facilities in Kentucky, where Kordsa will supply the carbon fiber fabrics via its U.S.-based company, Fabric Development Inc. Kordsa reports it has been sending shipments to the U.K. since November 2020.

“Through this project, we are now reinforcing a wider area of life with our new collaborations in the field of composites,” says Kordsa CEO Ali Çalışkan. “This valuable supplier agreement with TRB will enable the use of our carbon fiber fabrics in EV battery packs, helping reduce their weight without compromising their quality. We are pleased to work with TRB, with whom we share a similar vision for the future — to contribute to the world's successful transition to sustainable transportation.”

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

.jpg;maxWidth=300;quality=90)