L&L Furnace deliver atmosphere-controlled retort furnace for CMC

XLC3348 furnace model is tailored to produce lightweight CMC components for Midwestern aerospace manufacturer.

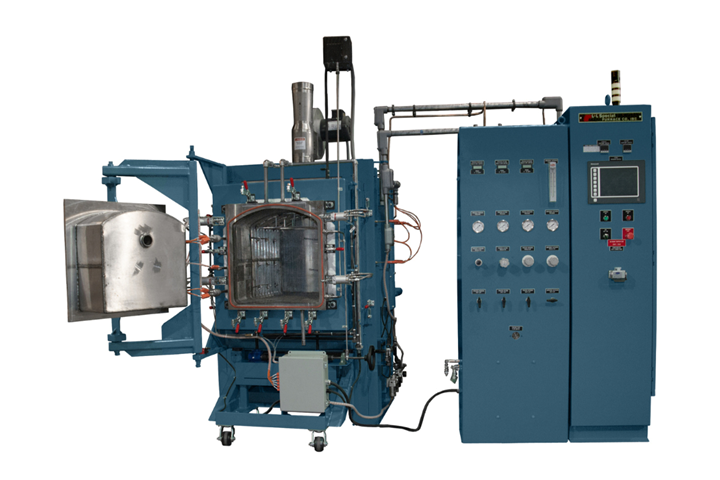

L&L Special Furnace Co. Inc. (Aston, Pa., U.S.) has delivered one of two model XLC3348 furnaces to a leading manufacturer of aerospace components in the Midwestern U.S. These furnaces will be part of a ceramic matrix composite (CMC) manufacturing facility providing lightweight aerospace components for commercial and military aerospace applications.

The nanothreads in the CMC process are coated with proprietary resins that need to be completely removed from the substructure using heat. It is also vital that there is no oxygen present during the process as this will significantly weaken the part structure.

The model XLC3348 has a work zone of 23 inches wide × 23 inches high × 36 inches deep. It has a single zone of control with a temperature gradient of ±14°C at temperatures between 650°C and 1,000°C using six zones of temperature control with biasing to balance any gradients.

The furnace is constructed of low-mass insulating firebrick, which enables quicker cooldown times. A venturi cooling blower is included that also aids in cooling. The XLC3348 is controlled by a Eurotherm Nanodac Mini 8 program mechanism with overtemperature protection. There is also a programmable flow panel to manage the nitrogen flow throughout the process.

The parts are heated to a set temperature in a retort chamber that is pressurized with nitrogen. The byproducts of the outgassing part are directed by pressure and flow out of the rear of the furnace. The parts are then heated in a vacuum furnace to temperatures in excess of 1,260°C. The result is a strong component that is lighter than titanium.

An independent flow panel is provided with an oxygen analyzer that monitors the oxygen content of the atmosphere on exit. This data is recorded electronically on the data acquisition station. An afterburner is included to clean the effluents as they exit the process chamber.

All L&L furnaces can be configured with various options and be specifically tailored to meet thermal needs. The company also offers furnaces equipped with pyrometry packages to meet the ASM2750 latest revision. Options include a variety of control and recorder configurations. An optional 3-day, all-inclusive startup service is provided with each system within the continental U.S. and Canada. International startup and training service is available by factory quote.

Related Content

-

ORNL, Sierra Space create novel C/SiC TPS for reusable space vehicles

CMC tiles will be used on the Sierra Space DC100 Dream Chaser spaceplane carrying critical supplies and science experiments to and from NASA’s ISS.

-

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

-

MATECH’s FAST technology achieves ultra-high density C/C composites

Targeting demanding hypersonic missile applications and ballistic reentry, the patent-pending process increases C/C composite ablation and oxidation resistance by 20 times.

.jpg;maxWidth=300;quality=90)