Hypersonix receives CMC scramjet manufacturing demonstrator

HTCMC component demonstrates manufacturing of future Spartan scramjet engine required for reusable hypersonic vehicles capable of up to Mach 12 flight.

Hypersonix has developed the DART AE hypersonic vehicle (top) as a single-use testbed using its patented Scramjet engine (center), for which it has received a high-temperature CMC demonstrator combustion chamber (bottom). Photo Credit: Hypersonix

Hypersonix (Sydney, Australia) has taken delivery of a technology demonstrator version of its hydrogen-powered Spartan scramjet engine manufactured in high-temperature ceramic matrix composite (HTCMC) from a leading European aerospace manufacturer. HTCMC parts are capable of resisting repeated cycles of extreme heating and cooling, which makes them a material of choice for Hypersonix’ planned re-useable hypersonic vehicles.

DART AE and Spartan scramjet

Hypersonix is currently building Dart AE, an unmanned hypersonic flight demonstrator as a test vehicle designed to enable customers to investigate flight conditions, data transmission and maneuverability at hypersonic speeds. Dart AE will reportedly also be able to gain valuable data and insights on hypersonic operations at a much more affordable price than is currently available from other hypersonic programs. The single-use Dart AE will be 3D printed out of high-temperature alloys, enabling quick turnaround between flights and a high cadence of testing as well as rapid availability of additional units.

The demonstrator is powered by the multi-award-winning and U.S. patented Spartan scramjet engine, which is now available in 3D-printed Inconel 718 in cooperation with Amiga Engineering (Tullamarine, Australia). This version of Spartan is capable of speeds of up to Mach 7.

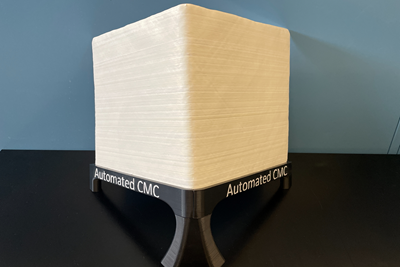

HTCMC demonstrator

The high heat generated by friction with air when traveling at speeds of Mach 5 or higher can compromise the structural integrity of hypersonic vehicle components. Hypersonix’ HTCMC technology demonstrator project has reportedly perfected the design and techniques required to offer a version of Spartan that can operate at up to Mach 12 and sustain repeated flights.

Customers are now expressing a need for such a vehicle, that is re-useable, with aircraft-like operation, including landing gear and flexible launch options. Hypersonix’ mission is indeed to enable affordable, sustainable access to space and greener aerospace technologies. The completion of the manufacturing pilot of a HTCMC scramjet is a major development for the company.

HTCMC are next-generation composites developed to handle the extreme heat and mechanical pressures required for a high Mach flight. Qualification of these materials for hypersonic applications requires manufacturing demonstrators that replicate the complex geometry of scramjets. These allow the analysis of hydrogen and air flows within the engine yet can be produced rapidly and economically.

A Spartan scramjet engine made using HTCMC will fly faster on longer missions, turning the self-igniting engine off and on again several times during the flight and skipping through the atmosphere like an airplane.

Michael Smart, CTO, head of R&D and Hypersonix cofounder says it was a huge moment for the engineering team to unpack this demonstrator for the composite version of Spartan. Designed by Hypersonix, he explains the demonstrator component was “produced in a very complex and never-done-before process working very closely over the last 2 years with a team of experts in Germany. We have been grateful for their willingness to take this project on and for bringing their expertise and input to the table.”

“Although we are focusing most of our energy this year on setting up our Dart AE manufacturing capacity, Hypersonix is already working on the next steps in our product roadmap,” says David Waterhouse, managing director of Hypersonix, “and taking the composite scramjet to a manufacturing-ready state. Australia is leading the world in scramjets and hypersonic technology; Hypersonix is looking to capitalize on our position, with the support of Commonwealth grants. HTCMC technology is in its infancy in Australia, so we are working with various parties to speed up applications, and would welcome orders from Australia and state government’s support in maturing and making HTCMC products here.”

Related Content

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreAirbus presents unmanned Wingman concept

Fighter jet model unveiled at ILA Berlin, made from an iron structure and composite outer skin, will deliver more tactical options, supporting future combat missions.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreRead Next

Purdue opens $41 million Hypersonics and Applied Research Facility

A dedicated 65,000-square-foot building is home to Mach 8 and HYPULSE wind tunnels to advance hypersonic evaluation and testing, and the HAMTC for materials and manufacturing work with partners.

Read MoreNCC successfully demonstrates AFP manufacture of CMC parts

Core Research program adapts existing AFP technology and identifies optimal deposition parameters using a novel 3M towpreg material for wider CMC use.

Read MoreStratolaunch completes separation test of Talon-A hypersonic vehicle

Stratolaunch takes one step closer to hypersonic flight with the demo of a clean and safe separation of its Talon-A vehicle from the Roc aircraft platform.

Read More