Montana State researchers introduce novel method for “stretch-broken” carbon fiber

New stretch-breaking concept consistently produces carbon fiber that is eight times more formable with strength equivalent to continuous fibers, enhancing its prospects to form to complex aircraft shapes and cut manufacturing costs.

MSU junior Morgan Hogue (left) and research engineer Dan Schwendtner (right) monitor a carbon fiber stretching machine in Doug Cairn’s lab on Nov. 9, 2022. Photo Credit, all images: MSU/Colter Peterson

For the past four years, a team of Montana State University (Bozeman, MSU) scientists, students and collaborators has developed an innovative way of making “stretch-broken” carbon fibers that are more easily formable to the complex shapes of aircraft and could significantly cut manufacturing costs. The project is funded by $25.8 million in contracts from the U.S. Army.

“We’ve invested a lot into this and now we’re approaching a major milestone where we’ll demonstrate actual manufacturing at a small scale before transferring the technology to industry,” Douglas Cairns, the lead MSU researcher on the project, says. He is a Lysle A. Wood Distinguished Professor in the Department of Mechanical and Industrial Engineering in MSU’s Norm Asbjornson College of Engineering. “We’re very excited about the potential impact.”

Traditional carbon fiber is the gold standard in the aerospace industry because it’s exceptionally strong and durable for its weight, Cairns explains. But the fibers are so stiff that forming them into the tight curves of an airplane wing, for instance, requires complex and expensive machinery. It also often requires a scaffold-like metal substructure that’s prone to corrosion, costing the U.S. military billions of dollars each year in maintenance and repairs.

By contrast, MSU’s new carbon fiber material — created by precisely stretching the material so that some of the fibers break at natural weak points — is reported to be about eight times more formable while being roughly the same strength, according to Cairns. That means the material can be shaped with simpler equipment and without metal substructure.

“Because it’s so much easier to form, we're conservatively estimating that we can lower the manufacturing costs by a factor of four,” Cairns adds. “That’s a huge deal.”

Although the concept of breaking carbon fibers to improve their formability has been around for decades, previous methods such as randomly cutting the material proved to significantly compromise strength, Cairns says, who has worked in aerospace materials for nearly 30 years. The idea of stretch-breaking also isn’t new, but until now nobody had figured out a way to consistently and efficiently do it in a way that could be scaled for industry. “The concept is easy, but the control of it is very difficult.”

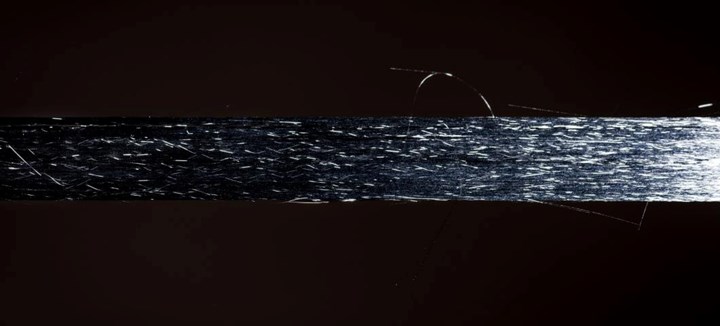

Working with nearly two dozen Montana companies to help with design and machining, the MSU team developed a novel stretch-breaking tool called the Bobcat Head. As a flat strand containing thousands of individual carbon fibers is rapidly passed through a series of rollers, precise force is applied to break the fibers where there are nicks and other imperfections. Only about 2% of the fibers are broken across a given area, Cairns notes.

Cairns says the project is already attracting attention from advanced material supply and aerospace companies.

The researchers then studied the properties of the resulting material. Roberta Amendola, associate professor in the mechanical and industrial engineering department, led a team of fellow faculty and students to test how easily the stretch-broken fibers could be bent into complex shapes and set with resin.

“The material keeps surprising us,” Amendola admits. “What we’ve confirmed is that it’s as strong as material made with continuous fibers but is very easy to form.”

The next step, according to Cairns, is to scale up the stretch-breaking machine for a pilot demonstration of how it could be used in actual manufacturing, which would pave the way for licensing the technology to aerospace companies that produce military and civilian aircraft. There’s the potential for the material to start being used industrially in the next few years, he believes.

In the meantime, the work is having an educational impact at MSU, with more than eight undergraduates and a dozen graduate students having contributed to the project. Other MSU faculty on the project include professor Dilpreet Bajwa and associate professor Cecily Ryan, both in the mechanical and industrial engineering department.

Federal appropriations for the $25.8 million in Army contracts for the project were supported by Montana Sens. Jon Tester and Steve Daines.

Cairns says the project is already attracting attention from advanced material supply and aerospace companies that have come to the Bozeman campus to see the material for themselves and are eager for material samples, which the MSU team is working toward providing. "When we talk with aerospace companies, their eyes light up,” he says. “They recognize how much this could impact their design and manufacturing."

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More