Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Composites enable next-generation rigid airship design. LTA Research’s Pathfinder 1, its first full-scale, electric-powered prototype airship, is shown here during construction in Mountain View, Calif., U.S. Composites are used for many of the airship’s structures, including the carbon fiber composite frame that can be seen through the partially open airship envelope. Photo Credit, all images: LTA Research

Today, large, rigid-framed airships are usually viewed only in black-and-white photos from the first half of the 20th century, popularized at the time by the zeppelins of Luftschiffbau Zeppelin GmbH (Friedrichshafen, Germany) and military airships like the U.S.S. Akron and the U.S.S. Macon. Tragic accidents to both of these airships, the German Hindenburg and others led to the eventual end of the rigid airship era both for passengers and cargo and, eventually, for militaries. Since the 1960s, today’s airships are mostly in the form of non-rigid blimps.

However, several companies are working toward a new generation of rigid, structured airships, working alongside Federal Aviation Administration (FAA) regulations and using contemporary technologies and materials to ensure safer manufacturing and operation.

One of these is airship company Lighter Than Air (LTA) Research (Mountain View, Calif., U.S.), which aims to create a new generation of airships that are inherently safer and faster than those previously built.

LTA’s CEO Alan Weston, who worked previously at the Air Force Research Laboratory (AFRL), NASA Ames Research Center and the Florida Space Institute at the University of Central Florida, started the company with the goal of reducing carbon emissions in air transportation. He decided to focus on modernization of electric or alternatively powered airships as a potential low- or zero-emissions air transport option.

In 2014, Weston began a deep dive into research on airship designs, starting with historians and researchers at the University of Akron and talks with airship designers from companies like Luftschiffbau Zeppelin GmbH and Goodyear Tire and Rubber Co.

As the research work progressed, Weston recognized that the airships he was developing had potential to augment humanitarian relief efforts, such as transport of supplies to natural disaster-stricken areas. Airships can dock virtually anywhere and do not rely on availability of intact airstrips or landing zones, can hover for a long period of time to pick up people or drop off goods and can be designed to carry large payloads, all qualities that could lend themselves well in relief efforts.

The company was officially founded in 2015 and backed by Google cofounder Sergey Brin. By 2016, LTA Research had two locations: an R&D lab in Akron, Ohio, U.S., to test design and manufacturing techniques, and a hangar in Mountain View, Calif., U.S. That year, LTA constructed and flew its first small-scale airship models in Mountain View and soon after began production of its first full-scale airship, Pathfinder 1.

Designing Pathfinder 1

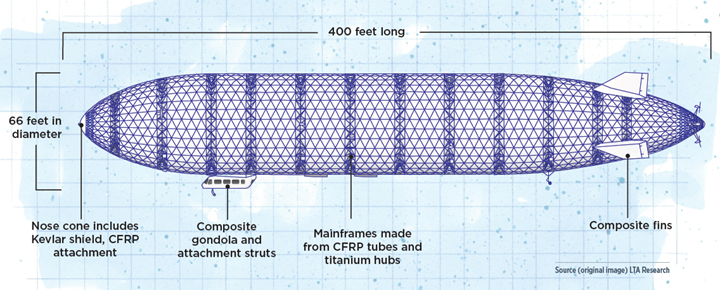

Pathfinder 1 is LTA’s proof-of-concept (POC) airship, paving the way for iterations to come, but it is no small-scale model, measuring just under 400 feet long and 66 feet in diameter, and powered by electric motors. Following qualification guidelines by the FAA, the goal is to prove out materials and manufacturing technologies, and to take any learnings into development of the next, even larger Pathfinder airships.

Daniel Morgan, VP of engineering at LTA Research, explains that the initial goals for Pathfinder 1’s overall design were safety and a simplified assembly process.

From the beginning, the company decided to target a rigid airship design, as opposed to a balloon-like blimp or a semi-rigid design. In a fully rigid design, helium bags still provide the airship’s lift but live inside a skeleton-like interior frame of interconnected tubes, in this case covered by a Tedlar (by DuPont, Wilmington, Del., U.S.) skin, called an envelope, which supports the gondola underneath the ship for holding passengers and cargo.

A rigid design provides the most strength to carry cargo and modern navigational and safety systems, but more structural components also mean more added weight to the overall airship, potentially reducing range or payload capacity.

Therefore, LTA recognized that composites would likely be used in some capacity to keep the airship’s weight as low as possible at maximum strength.

Morgan explains that LTA used early 20th century airship designs as a foundation, modernized with today’s materials, manufacturing techniques, and propulsion and navigation technologies, “and composites fall into that category of modern materials. Legacy airships were often built using aluminum or even wood in at least one case, but when you compare stiffness and weight, composites are the clear solution for our application.”

Siemens (Alpharetta, Ga., U.S.) Femap finite element analysis (FEA) software and Ansys (Canonsburg, Pa., U.S.) simulation software were used to design each of the airship’s structures.

“Composites were used in a number of places where lightweight structure is needed,” Morgan says. Carbon fiber, Kevlar and fiberglass are all used depending on the required weight, stiffness and impact resistance properties.

Composite components include the gondola, built by partner Zeppelin; gondola attachment struts; the multi-component, multi-material nose cone, also built in partnership with Zeppelin, which includes a Kevlar shield and a carbon fiber-reinforced polymer (CFRP) attachment mechanism; fins; fiberglass composite motor covers; a roll-wrapped, out-of-autoclave (OOA) cured composite motor pylon; hand laid and press-cured gangway planks; and external air intake vents and mounts fabricated via a mix of autoclave and OOA hand laid composites.

For a rigid airship like Pathfinder 1, arguably the most important structural elements — certainly the largest, besides the envelope — are the 13 tube-shaped mainframes. For these, Morgan says carbon fiber composites were the top contender from the beginning. “From out of the gate, we were interested in something that was going to be extremely safe and extremely strong.”

Manufacturing and assembling the Pathfinder 1 frame

“The frame is designed with today’s materials in mind,” Morgan explains. “Carbon fiber’s compressive strength versus aluminum or wood automatically changes the overall structure that you develop, because it carries the load differently.” At the same time, he says that LTA didn’t want to completely reinvent the wheel. “If you look at the old designs of airships, they use a similar geodesic pattern much like we do, although many of those were truss-based systems,” meaning, in a semi-rigid airship design, a keel or truss along the bottom of the structure supporting the helium-inflated envelope above.

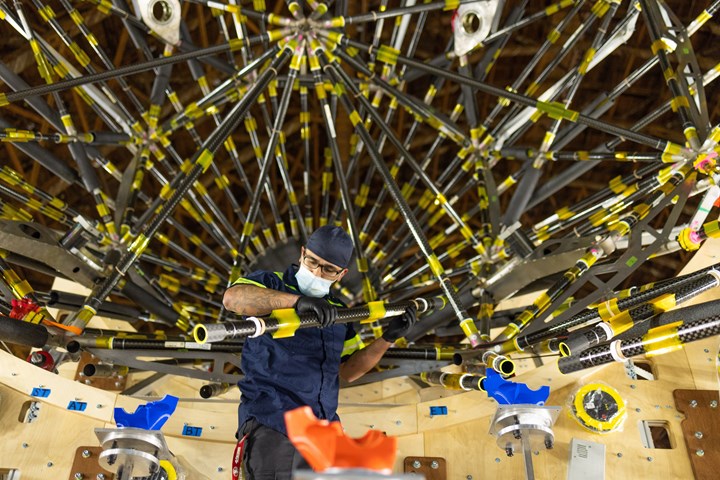

Modernizing the rigid airship frame. LTA Research based its airframe on rigid airships from the 20th century, but with contemporary materials and new, safer assembly techniques. The frame for Pathfinder 1 is composed of more than 10,000 hollow carbon fiber composite tubes connected to titanium hubs.

For LTA’s frame, high strength and low weight were the top considerations; in addition, to simplify the qualification process, LTA decided to lean on existing aerospace-qualified materials. These goals led to a design featuring hollow tubes made from aerospace-grade carbon fiber prepreg, connected by a series of specially designed, welded titanium hubs. The overall Pathfinder 1 frame is composed of almost 3,000 welded titanium hubs connecting 10,000 multi-ply CFRP tubes.

To simplify assembly, LTA decided on two tube configurations, approximately 3 and 4 inches in diameter, respectively, which are cut to a variety of lengths of up to 12 feet. After testing samples from several suppliers, the company partnered with Kilwell Fibrelab (Rotorua, New Zealand), which specializes in composite tubes for a variety of applications.

For Pathfinder 1, the tubes are manufactured via a roll-wrapping process, where the prepreg sheets are cut to a specific size, then laid up in specified layers around a mandrel by hand. A heated shrink tape layer is added to the tubes for compaction, followed by an oven cure cycle. Aerospace-qualified carbon fiber prepregs from Toray (Tokyo, Japan) are used, both a spread-tow plain weave intermediate modulus (IM) prepreg and a unidirectional high modulus (HM) prepreg, with a proprietary resin.

Craig Wilson, CEO at Kilwell, explains that roll-wrapped composite tubes are the company’s “bread and butter,” but upgrades were needed to Kilwell’s facility and process to meet LTA’s and the FAA’s quality standards, including temperature, humidity and particle management systems to the facility, and a new process for barcoding and data tracking for each process step for each part.

“We developed a more specialized cure cycle compared to some of our other projects, requiring a higher temperature and longer cure cycle to meet the requirements, and all data is monitored and tracked,” adds Jason Daniels, production manager at Kilwell.

Miles of CFRP tubes. New Zealand-based Kilwell Fibrelab used a roll-wrapping and oven cure process to produce the tubes assembled onto Pathfinder 1.

Wilson notes that since the first sample tubes were fabricated in late 2016, as of late summer 2023, Kilwell has produced 24,840 tubes with a total length of more than 25 miles in support of LTA’s Pathfinder program.

Beyond the tubes themselves, another challenge to the frame structure was assembly. In the past, airships were very labor-intensive to assemble, Morgan says, requiring hundreds of people from dozens of specialized disciplines, many of whom had to work rather perilously from scaffolds. “Today, we can use modern techniques to front-load the process, using more in the way of engineers and automation and greatly reducing touch labor,” he says.

In fact, LTA has patented a number of apparatuses designed to facilitate faster, safer construction. Essentially, mainframe tube and hub components are attached to a circular, universal mainframe jig built to the same diameter as the airship, suspended from the ground by support structures. Components are attached to the jig by technicians on the ground, and then the entire apparatus is rotated to lift that section of the mainframe to the required height.

This assembly method, and the tubes and hubs themselves, are all designed to be easily scalable, as LTA begins to look beyond Pathfinder 1 to even larger airships in the future. “That’s what’s really a game changer with the architecture we’re using,” Morgan says, “that scalability. If we want to build an airship of a different size, we can use the same techniques, using the same tools and analysis techniques to design the airship and build it relatively quickly using the same or similar carbon fiber tubes.”

Future Pathfinders: Larger airships, higher volumes

Right now, the focus is getting Pathfinder 1 in the air, but the airship ultimately serves as a POC for more, even larger airships to come.

Composites-intensive design. In addition to the CFRP frame, a variety of composites were used on the Pathfinder 1 by LTA and its manufacturing partners. These include the fins (pictured), gondola, motor covers and more.

To support an increase in airship size, LTA needed a larger manufacturing space. In 2022, the company acquired the 1,175-foot-long, 325-foot-wide and 211-foot-high Akron Air Dock in Akron, Ohio, U.S., a massive, historical structure built in the 1920s by the Goodyear Zeppelin Corp. (a joint company at the time between Goodyear and Zeppelin) that has been the build site for many blimps, airships and other aircraft. Morgan says, “When we were looking at building a larger ship, we knew that we needed to find another home for it, and Akron is the origin of the airship industry. There’s so much historical knowledge.”

Currently on the drawing board is the next airship in the Pathfinder series, similar in design to Pathfinder 1 but significantly larger — more than 600 feet long and 98 feet in diameter.

Morgan says the next Pathfinder “will largely follow in the footsteps of Pathfinder 1 in terms of design, using large amounts of composites where they can be used on the airship. It’s a design evolution, not a revolution.” He notes that changes to materials and manufacturing decisions may be made, as lessons are learned from ongoing tests for Pathfinder 1, especially as the company seeks to accommodate larger part sizes and looks toward commercial production in future, higher manufacturing volumes.

The CFRP frame components are a prime example of this. “Going into the next iteration, we’re looking for the same strain-to-weight ratios, the same performance for the frame components, but we need a high-volume manufacturing method,” Morgan explains.

About three years ago, when looking into processes that would enable more efficient and scalable manufacturing of frame components, LTA connected with Exel Composites (Vantaa, Finland), which specializes in pultrusion and pull-winding of composite tubes and profiles. Morgan explains, “Exel’s expertise in bulk manufacturing and automated manufacturing was the reason we selected them.”

The main goals were repeatability and volume, while meeting strength, endurance, toughness and stiffness requirements. It was decided that Exel’s pull-winding process was the best fit. Pull-winding essentially combines filament winding and pultrusion: like in pultrusion, carbon fiber tows are guided through a resin bath and then into a heated die to be shaped into the final part. In the pull-winding process, however, some of the tows are not pulled straight through in a linear fashion but are wound helically around a mandrel, which allows for fibers of various alignments for added strength and design flexibility. Like pultrusion, the process is continuous and profiles are subsequently cut to length.

Flight-ready. As of late summer 2023, Pathfinder 1 is fully built and ready for flight tests in California. LTA plans to take design, manufacturing and operation knowledge from the airship into its next generation of larger, production-targeted airships to be built in Akron, Ohio, U.S.

“It’s much more automated than a manual wrapping process, and consistency is very high. It’s a continuous process that precisely places every fiber exactly where it needs to be,” explains Marc Tagher, area sales manager – U.S., at Exel Composites.

“The pull-winding technique allows us a little more flexibility,” Morgan adds, “and because the process uses tows instead of fabric, we’re able to schedule laydown of the windings specifically to meet our needs.” For example, winding the fibers around a mandrel adds hoop strength to the tube even with a relatively thin wall. In addition, “compared to hand layup roll wrapping, pull-winding is roughly an order of magnitude faster, and even offers cost savings with a large enough manufacturing run.”

Switching from the current prepreg roll-wrapping process to pull-winding also involves new material selection. Exel’s tubes are made from a mix of HM and IM carbon fibers, and a proprietary resin said to be selected for a combination of high performance and compatibility with the pull-winding process.

Exel’s R&D teams in Finland have been working on optimizing various iterations of the tubes, which are then sent to LTA for mechanical testing. Once mass production of these tubes begins, Exel plans to move production to its facility in Erlanger, Ken., U.S.

Flight tests and future airships

Currently, the success of Pathfinder 1 is LTA’s top priority. The first airship was completed in early 2023 in Mountain View and as of mid-2023 has completed several indoor flight tests. Through the rest of this year, LTA says its goal is to move into the next phases of outdoor flight testing, as well as continued training for its team of certified pilots and experienced flight crew.

Following the successful rollout of Pathfinder 1, LTA’s goal is to ultimately manufacture a series of airships out of the hangar in Akron, Ohio, U.S.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Luxury travel by airship returns

A look at composites on the Airlander 10 hybrid aircraft by Hybrid Air Vehicles, a helium-filled airship. HAV made a splash at Farnborough this year by announcing luxury tourist travel.

Read MoreAirlander 10: The future of zero-carbon aviation

Lighter-than-air flight is making a comeback with Hybrid Air Vehicles’ Airlander airliner and it’s taking composites and sustainability to the next level.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)