NASA prepares for phased testing of its first all-electric X-plane

Flight testing of the X-57 Maxwell will assess its electric cruise motors and composites-intensive, high-aspect ratio wings.

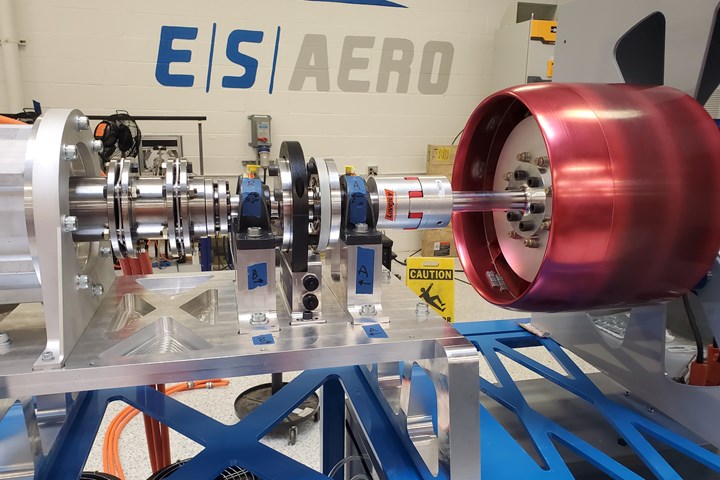

As part of the verification and validation process, the all-electric cruise motors to be used on NASA’s X-57 Maxwell began several rounds of tests, high power, and endurance testing at Empirical Systems Aerospace, or ESAero. Source: Empirical Systems Aerospace

NASA (Washington, D.C., U.S.) reported it has made significant progress on its first all-electric X-plane, the X-57 Maxwell. In addition to completing tasks for the aircraft’s functional ground testing at its Armstrong Flight Research Center in Edwards, Calif., U.S., assembly and qualification tests are underway on two critical vehicle components, the electric cruise motors —which will power X-57 in flight — and the high-aspect ratio wing, which makes extensive use of composites, that will fly on the aircraft in its final configuration (see CW’s “NASA all-electric experimental aircraft to begin ground testing” ).

Modified from a Tecnam P2006T airplane, NASA says the X-57 is currently in its first of three configurations as an all-electric aircraft, called Modification II, or Mod II. While this configuration features the replacement of the vehicle’s standard combustion 100-horsepower Rotax 912S engines with 60-kilowatt electric cruise motors, the company notes X-57’s test flights in this phase will be performed using the vehicle’s standard wing.

The following phase, Mod III, will see the standard wing replaced with the high-aspect ratio wing, which NASA says will reduce overall vehicle area. Additionally, for its final Mod IV configuration, the company says it will relocate the cruise motors out to the wingtips. This configuration also will feature 12 small, high-lift motors along the wing’s leading edge to be activated during takeoff and landing. The electric cruise motors will remain constant through the configurations, and are already being tested at Empirical Systems Aerospace (ESAero, San Luis Obispo, Calif.), — NASA’s prime contractor for the project — before being installed into the X-57 vehicle itself.

“All three mods of X-57 will utilize the same cruise motors. We’re putting them through functionality tests, acceptance tests and qualification tests to ensure their airworthiness for the X-57 vehicle,” says Trevor Foster, ESAero vice president of operations. “As part of the NASA airworthiness process, these are the verification and validation steps to reduce risks and increase the safety and reliability of the components on the vehicle.”

This artist’s concept image shows NASA’s first all-electric X-plane, the X-57 Maxwell, in its final configuration, flying in cruise mode over NASA’s Armstrong Flight Research Center in Edwards, Calif. U.S. In Mod IV test flights, X-57’s high-lift motors will deactivate during cruise mode and their propeller blades will fold into the nacelles to reduce drag. The motors will reactivate and use centrifugal force to spin the blades back out to provide necessary lift for landing. Source | NASA Langley/Advanced Concepts Lab, AMA Inc.

NASA states these steps include endurance and high-power testing of the cruise motors and cruise motor controllers, with a focus on monitoring overall system efficiency. To do this, engineers use a dynamometer to measure current and voltage, taking in data at a rate of 2 million times per second. From there, the performance of these components can be recorded, analyzed and augmented as necessary to achieve maximum efficiency. “So far, the motors and controllers have performed exceedingly well, and we’re in the process of getting them to perform even better,” Foster says.

While X-57 will always fly with a pair of cruise motors in each configuration, NASA has built a total of five motors for the project. One was disassembled and used for evaluation of the unit’s construction as a safety measure, two will be used as flight motors on the X-57 aircraft, and the other two will be used for envelope expansion testing, acting as spares to the flight motors. Lessons learned from these tests are helping pave the way for future U.S. Federal Aviation Administration (FAA) airworthiness standards for electric aircraft, says Foster.

“It’s critical for the success of the project that we, one, achieve the efficiency goals that we’re looking at, but also, as we’re going through these steps, we’re beginning to develop how anyone else in the industry is going to certify or make airworthy motors,” said Foster. “We’re taking those first steps.”

As the cruise motor tests directly feed the effort for X-57 Mod II, NASA says preparation for Mods III and IV are well underway, with the team getting the vehicle’s new wing ready for integration. An additional P2006T fuselage, off the same assembly line as X-57’s fuselage, was acquired, and is acting as a “tooling” fuselage, allowing engineers to assess the best way to integrate the wing, designed by Xperimental LLC (San Luis Obispo, Calif., U.S.), to X-57 for Mods III and IV, and troubleshoot any challenges with the attachment. The wing is also undergoing instrumentation development, as engineers work to finalize the positioning of hardware inside the wing to accommodate X-57’s complex distributed electric propulsion system.

“We’re working to figure out the right positioning for specific instruments, and how to mount them,” says Phil Osterkamp, ESAero vehicle instrumentation lead. “It’s a small wing, and the challenge is to get all these items fitted onto and inside it, and trying to understand how to make this as light and as small as possible. It’s a lot of layout and routing.”

This is being done as a risk reduction for X-57, which will be the first NASA X-plane in two decades to have a test pilot onboard, but also as a schedule reduction effort. With these activities taking place in parallel to Mod II, the transitions from Mod II to Mods III and IV will require less time.

“The work being done now for X-57 is extremely important,” says NASA’s X-57 project manager, Tom Rigney. “The team is proving out the key electric components that will very soon set the stage for all the parts to come together and for on-aircraft ground testing to begin.”

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

NASA names companies to develop human landers for Artemis

Blue Origins, Dynetics and SpaceX are developing human landing systems concepts for Artemis’s 2024 moon mission.

Read MoreSuccessful tower extension test for James Webb space telescope

The test ensured the tower extensions on NASA’s composites-intensive telescope would keep the structure cool enough to detect infrared light.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)