Novo Navis develops process to manufacture 3D woven, machinable carbon fiber

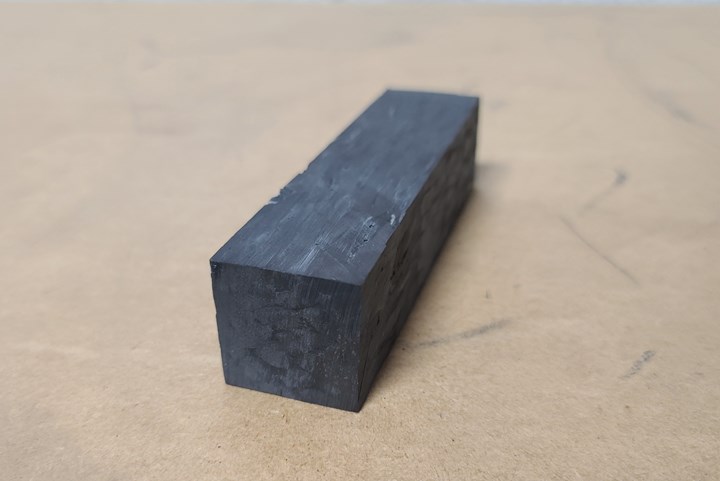

The ability to create solid blocks of woven carbon fiber presents the opportunity to create complex load bearing structures for aerospace applications.

Source | Novo Navis

Aerospace company, Novo Navis’ (Phoenix, Ariz., U.S.) Fiber Dynamics division recently announced that it has succeeded in developing a weaving loom that creates solid blocks of 3D woven carbon fiber material that can be machined or milled, just like aluminum. Novo Navis says its “patent pending” advancement in composite technology opens the doors for aerospace and astronautical engineers to create complex load bearing structures from carbon fiber, which until now, is said to have been out of reach.

Novo Navis says current carbon fiber technology involves weaving carbon fiber yarns into fabric which is then sandwiched together, and precludes machining or milling due to the delamination of the fabric panels. With the ability to create solid blocks of woven carbon fiber, the company notes that delamination is no longer necessary.

According to the company, the technology was enabled via the creation of the “bi-axial heddle,” a proprietary technology that could develop weaving sheds in two directions. This is said to have also enabled complete scalability of the technology; blocks as large as a cubic meter can be produced on the same machine.

Novo Navis says this ability to create blocks of solid woven carbon fiber that can be machined or milled now gives aerospace and aeronautical engineers opportunity to build load bearing components from a material that is 45% the weight of aluminum, yet stronger than steel.

The company recently was awarded a Phase 1 SBIR award from the U.S. Air Force to develop the material for military applications. The material is now available for the civilian markets and businesses can contact the company to discuss their specific needs.

Related Content

-

KraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

-

Glass fiber-reinforced Akulon RePurposed recyclate enables Ahrend sustainable office chair

Envalior 30% glass fiber-reinforced Akulon RePurposed material helps Ahrend achieve lighter task chair with closed-loop value chain and reduced emissions.

-

Babyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.