On the radar: Achieving thermal conductivity of composites

Recent progress incorporating fillers into fiber-reinforced polymer (FRP) materials have reported enhanced thermal properties, or better thermal management, guiding FRPs into new market opportunities.

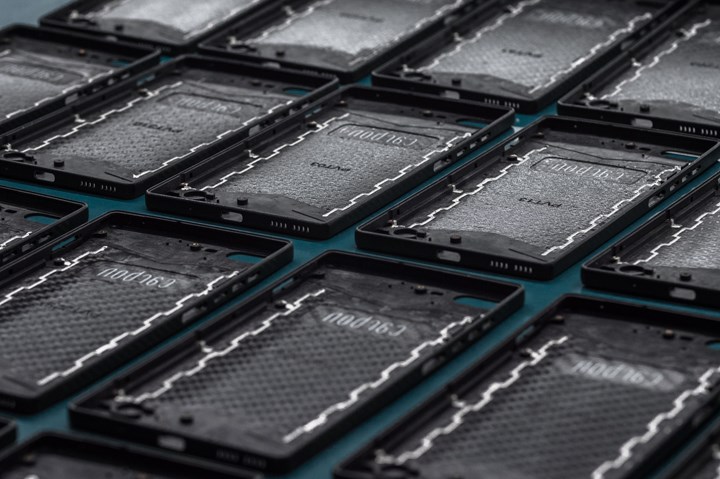

Carbon Mobile and SABIC are developing and deploying advanced carbon fiber in connected devices. Photo Credit: Carbon Mobile

Thermal/electrical conductivity is usually relatively low on the capabilities spectrum of fiber-reinforced polymer (FRP) materials. Ultimately, this property is a function of many things — resin type, fiber type and architecture, fiber volume fraction, direction of heat flow and service temperature. Nevertheless, composites’ attractiveness for the electronics markets, or aiding in thermal management (e.g., dissipating electrostatic), grows every day as their other benefits — weight-to-strength ratio, stiffness, flexure strength and other mechanical properties — are realized through other applications.

A variety of studies over the years have noted that thermally conductivity fillers — though these vary — successfully contribute to the enhancement of FRP thermal conductivity. CW has seen a similar trend, most notably through the addition of graphene (read “On the radar: Advancing the application, adoption of graphene-reinforced composites”), but also additional methods, such as better controlling the orientation of fibers.

Below are a few resources worth noting:

- This smartphone design from Carbon Mobile overcomes carbon fiber’s tendency to block radio frequency (RF) signals while also enabling isotropic grounding and electrostatic discharge (ESD) solutions.

- Development of cellulose nanofiber-carbon fiber composite films maintain the performance of electronic devices.

- A new graphene nanotube concentrate demonstrates permanent, stable conductivity in thermoplastic composite applications, as well as these composite printing sleeves.

- An ESA project, HITEC, aims to mature materials and manufacturing technology for producing thermally and electrically optimized composite structures for use on space structures.

- A university’s proposed method is said to control the orientation of composite fillers without surface modification, improving thermal management.

For additional “On the radar” trends articles, click here.

.jpg;maxWidth=300;quality=90)