Quantum composites research opens new avenues in energy storage, electronic applications

A new type of composite material studied by the University of California, Riverside features unique properties defined by quantum condensate effects, presenting new approaches to materials engineering and utilization.

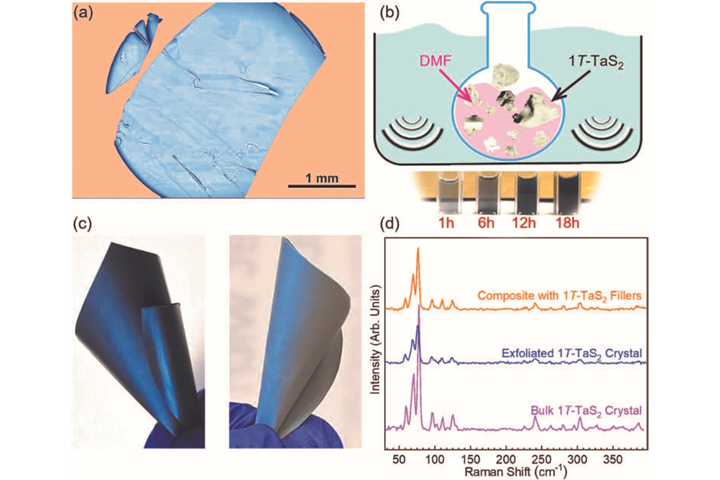

Figure 1. Quantum composites with charge-density-wave quantum materials. (a) Scanning electron microscopy image of 1T-TaS2 crystals (b) illustration of the chemical exfoliation method using low-power bath sonication (c) flexible composite films with 1T-TaS2 fillers (left) and dual 1T-TaS2 and h-BN fillers (right) (d) raman spectra of the bulk 1T-TaS2, exfoliated fillers and dilute epoxy composites with 1T-TaS2 fillers at T = 93 K. The Raman spectra reveal the presence of the charge-density-wave quantum condensate phases after all processing steps. Photo Creidt: Zahra Barani, Fariborz Kargar and Alexander Balandin

Recent years have witnessed fast-growing interest in quantum strongly correlated materials that show unusual electronic, optical and magnetic properties, including metal-insulator transitions, superconductivity and charge-density-waves quantum condensate phases. Materials that reveal quantum phenomena are typically crystalline, chemically pure and have low densities of defects since defects and disorder lead to the collapse of the quantum states — because of this, composites, with their combination of two or more materials with different properties and thus a disordered material, have not been considered under this lens. However, recent work by a University of California – Riverside research team led by Professor Alexander Balandin has reported on quantum composites based on polymers with fillers comprised of a van der Waals material, 1T-TaS2, that reveals multiple quantum condensate phases.

Optical, thermal and electrical characterizations indicate that the quantum states persist after harsh composite processing steps. The macroscopic properties of the composites show signatures of the transition between the charge-density-wave quantum phases even above room temperature.

The quantum composites studied revealed unusually high dielectric constant — more than two orders of magnitude enhancement — while remaining electrically insulating. The latter opens up possibilities for the application of these materials in energy storage and electronics (see Fig. 1).

The breakthrough results have been reported in a paper, “Quantum Composites with the Charge‐Density‐Wave Fillers” published in Advanced Materials. The first two authors of the paper, Zahra Barani and Tekwam Geremew, are Ph.D. students in the Phonon Optimized Engineered Materials (POEM) research center led by Professor Balandin.

If implemented, one can possibly develop novel composites with electrical and optical properties not achievable by other means.

The obtained results are said to present a conceptually different approach for engineering the properties of materials. They also extend the application domain for the layered van der Waals materials.

“It has been known for a long time that some charge-density-wave materials exhibit extraordinarily high dielectric constant,” Balandin explains. “The physical mechanism of this effect has been explained and accepted by the research community. However, there was no practical utility of this property — such dielectric properties were observed in the brittle crystalline bulk samples, which are highly electrically conductive. We achieved exceptionally high dielectric constants in dilute composite samples, which are electrically insulating and flexible. The enhancement in the dielectric constant is observed above room temperature, more specifically, at the temperature of the operation of electronic devices.”

The anomalously high dielectric permittivity of the polymer-based dilute composites with the charge-density-wave quantum fillers exceeds many previously reported composites and offers potential for a range of innovative applications related to variable capacitors, capacitive sensors, capacitors for energy storage and reflective coatings. The temperature range at which the dielectric constant of the quantum composite drastically changes is said to be close to the operating temperature of many electronic devices, increasing the feasibility of energy applications of such composites.

Another aspect of the practicality of any new type of composite is production cost. Exfoliated van der Waals fillers can be produced via the scalable and cost-effective liquid phase exfoliation technique. It is already being used for the processing of graphene fillers for thermal interface materials. A natural extension of the concept of quantum composites with the charge-density-wave fillers would be the use of the one-dimensional van der Waals quantum materials that reveal the strongly correlated quantum and topological phenomena.

Additional challenges that have to be dealt with in this research direction would include uniform dispersion of the high aspect ratio quasi-1D fillers and control of the polytypes of the synthesized materials. According to the research team, if implemented, one can possibly develop novel composites with electrical and optical properties not achievable by other means.

Provided by Nanowerk.com and University of California – Riverside.

Read Next

3D-printed, self-assembled graphene demonstrates potential for hierarchical composites

A 3D-printed template-directed assembly method assembles graphene into a multi-scale programmed structure with tunable mechanical properties, low density and high Young’s modulus.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More