Qarbon Aerospace partners with Georgia Tech to address advanced structures in civilian vertical lift vehicles

Demonstration, testing, repair and maintenance of thermoplastic airframe structures will address technical barriers and make a business case for use of composites, metamaterials and AM for civilian air mobility.

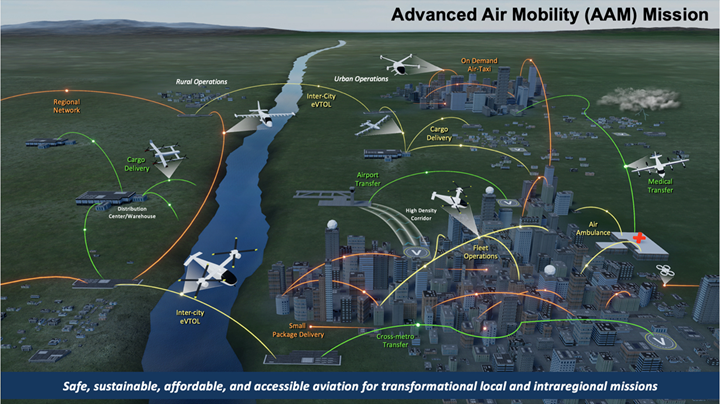

Qarbon Aerospace Inc. (Red Oak, Texas, U.S.) has partnered with Georgia Tech (Atlanta) to participate in NASA’s (Washington, D.C., U.S.) $5.37 million University Leadership Initiative (ULI), to address the technical barriers associated with developing advanced structures for civil vertical lift vehicles. As a partner, Qarbon Aerospace will be leading the innovation and manufacturing demonstration for urban air mobility (UAM) airframe structures and testing the use of thermoplastic components, as well as the repair and maintenance of advanced structures.

“We’re focused on making the business case to use advanced materials for civilian air mobility,” Marilyn Smith, professor in the Daniel Guggenheim School of Aerospace Engineering at Georgia Tech and principal investigator for the project, notes. “These materials include composites, metamaterials and additive manufacturing [AM]. We’re not just addressing the materials, but the costs over their lifetime, including fatigue life, the costs and labor required for repair and maintenance scheduling.”

Smith adds that the operational costs for general aviation aircraft, such as traditional piloted helicopters, are more expensive than the costs envisioned for these new civilian advanced air mobility (AAM) vehicles. For example, the Federal Aviation Administration (FAA, Washington, D.C., U.S.) currently requires aircraft to have a thorough inspection at set time intervals which would be very costly in time and money for AAM’s operating continuously. Therefore, a new approach to inspections could possibly be determined.

“The premise of our project is to look at this from a material standpoint — everything from composites to new materials under development,” Smith says in a Georgia Tech announcement. “We will then determine an approach emphasizing safety where we can estimate when inspections are needed, and when components need to be replaced, rather than relying on a set maintenance schedule.”

The research team at Georgia Tech is equipped to look holistically at maintenance and safety by partnering with Middle Georgia State University’s School of Aviation to determine what level of mechanic would be needed for routine maintenance and repairs. Qarbon Aerospace will fabricate a large fuselage demonstrator, and study effects of defects in thermoplastic composites as well as structures testing.

“We greatly appreciate Georgia Tech and NASA’s leadership in bringing together industry and academia on projects to advance the future of urban air mobility,” Evan Young, head of engineering for Qarbon Aerospace, notes.

In addition to these research objectives, the Georgia Tech team plans to focus on several outreach initiatives that mentor and increase STEM awareness and participation for K-12 students in the rural south, where STEM outreach lags in a growing population. Recent studies indicate that this growing population of women and underrepresented minority groups from lower socioeconomic levels will fuel the workforce over the next century.

The team also includes researchers from the University of South Carolina (Columbia) and North Carolina A&T State University (Greensboro). This is said to be first time Georgia Tech has led a NASA ULA and Smith, along with Professor Karen Thole at Penn State University, earned the distinction of being selected as the first women lead principal investigators on a NASA ULI, which is in its fourth round of awards. Both women are recognized as leaders in their respective technical fields of research in aerospace engineering. Thole is currently collaborating with aerospace engineering professors Timothy Lieuwen and Brian German on improving commercial hybrid-electric aircraft.

“It is exciting to be able to represent Georgia Tech in its first lead organizational role for a NASA ULI,” Smith adds. “This ULI will engage five diverse faculty from the School of Aerospace Engineering to support NASA’s mission, and we have plans to engage students here at Georgia Tech and in the state of Georgia to expand STEM education in this field. We are especially pleased to team with our colleagues in the Aviation Maintenance and Structural Technology program at Middle Georgia State University.”

Qarbon Aerospace, headquartered in Red Oak, Texas, is a leading provider of large, complex composite and metallic structural components and assemblies such as fuselages, wings, flight control surfaces, and engine nacelles and components.

Related Content

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Qarbon Aerospace ships first completed HEXA eVTOL aircraft

The composite aircraft, designed by LIFT Aircraft, was manufactured, assembled and integrated by Qarbon Aerospace.

Read MorePlant tour: Qarbon Aerospace, Milledgeville, Ga. and Red Oak, Texas

Veteran aerostructures Tier 1 transforms into 21st century leader in thermoplastic composites and multiple new markets.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More