3D-printed, self-assembled graphene demonstrates potential for hierarchical composites

A 3D-printed template-directed assembly method assembles graphene into a multi-scale programmed structure with tunable mechanical properties, low density and high Young’s modulus.

Share

Read Next

Over the past decade, researchers have made significant progress using additive manufacturing (AM) techniques to produce precisely tailored lattice structures from the micro- to macro-scale, resulting in artificial materials inspired by the high-performance multi-scale structures of natural structural materials such as wood and shells, such as recyclable liquid crystal polymers. While “structural control from the nano- to the macro-scale is still a major challenge due to the limited ability of existing manufacturing methods to control multi-scale hierarchical structures with high complexity,” according to Ling Qui, an associate professor at Tsinghua Berkeley Shenzhen Institute, graphene — which possesses a variety of properties like ultra-low density, high compressibility, specific surface area and electrical conductivity — is being considered as an ideal building block to generate versatile 3D networks from controlled self-assembly, even if has remained challenging to fabricate 3D pure graphene structures with high structural complexity.

“Therefore we would like to combine the strength of the fabrication method and material features, to preserve the pristine properties of functional materials [like the low density and large deformability for graphene structures] and to study their structure-dependence,” Qiu explains the background for the team’s latest work, reported in Advanced Functional Materials, “3D Printed Template-Directed Assembly of Multiscale Graphene Structures.”

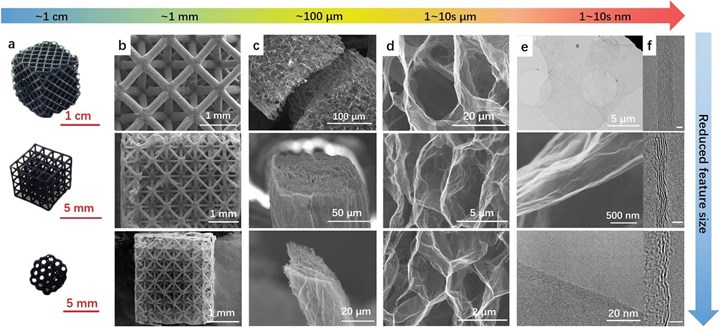

In this work, the team used graphene as the model building block, just like a Lego piece. By using a 3D-printed template and self-assembly technique, the graphene “Lego pieces” can be assembled into a programmed structure from nano- to macro-scale, enabling the fabrication of materials with complex, tailorable feature size crossing a record seven orders of magnitude — from nanometers to centimeters. This reportedly resulted in the fabrication of graphene structures with tunable mechanical properties, from rigid (modules one order of magnitude higher than other ultralight materials) to super-elastic (able to recover from extreme 95% compression). The result, according to Qiu, is a material with a density of 0.08 milligram per cubic centimeter, which is 15 times lower than the density of air.

Qiu notes that this research not only provides a facile approach to fabricate programmed graphene structures, but reveals the possibility of customizing its properties by rational design of multi-length scale structure towards a plethora of applications.

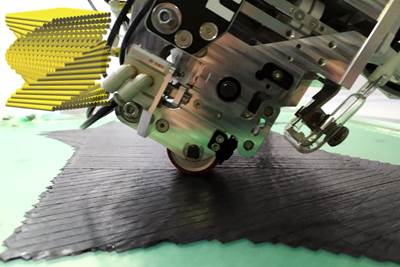

“Our work provides a potentially universal method to create diverse 3D structures with high resolution, multi-scale design using different functional nanomaterials, thereby expanding the fabrication capabilities of existing 3D printing techniques,” Jingzhuo Zhou, the paper’s first author, points out.

Structure of MSGSs with controllable features across seven orders of magnitude in size. Photo Credit: Jingzhuo Zhou,Xin Wu,Yan Chen,Chuang Yang,Rui Yang,Junyang Tan,Yilun Liu,Ling Qiu,Hui-Ming Cheng. “3D Printed Template-Directed Assembly of Multiscale Graphene Structures.” Advanced Functional Materials. 2022. Volume 32, Issue 18. Copyright Wiley-VCH GmbH. Reproduced with permission.

Although there have been several reports about the macroscopic structures derived from 3D-printed templates, they are said to mainly focus on the compositions of the injected materials (e.g, field-responses of magnetic fluid) with the 3D-printed polymer (or the remaining carbonized skeleton) as structural support. In contrast, the novelty of this work lies in the controllable self-assembly of graphene sheets inside the template, which enables much higher precision control of the structure than previous works with pure functional materials (template completely removed).

In general, the mechanical strength (such as Young’s modulus) of bulk materials degrades exponentially with decreasing bulk density, which limits the development and application of lightweight materials. But thanks to this novel fabrication technique, the fabrication of structures with record-low density and record-high modulus becomes possible.

The graphene structures demonstrated in this work, for example, can achieve ultra-low density (mainly in the range of 0.1-1 milligram per cubic centimeter) and corresponding ultra-high stiffness (Young’s modulus is an order of magnitude higher than that of reported materials with the same density).

The team also used their graphene structures for the fabrication of ceramics. Generally, fabricating multi-level ceramic structures is difficult; the microstructure cannot be easily controlled and the macrostructure is hard to process. By using the novel graphene structures as templates, combined with deposition techniques, the researchers showed that it is possible to obtain pure ceramic structures that replicate the graphene hierarchical structures after air sintering.

“Our 3D-printed template-directed assembly method can be applied to other polymers or nanoparticle colloidal dispersion systems, expanding the range of materials that can be fabricated into elaborately tailored architectures,” Qiu notes. “The realization of high design freedom of multi-length scale structure provides a materials platform for systematic research on structure-property relationships. Last but not least, the nearly unlimited structural design freedom for a range of potential materials offers virtually infinite possibilities for the creation, optimization, and customization of application-oriented architectures.”

For example, this method could provide a potential universal solution to the manufacture of 3D electrodes in energy storage devices with customized fine structures for easy electrolyte permeation and fast ion diffusion, thus enabling optimized areal energy density and power density.

Read this full, original article by Nanowerk’s Michael Berger here.

Read Next

Creating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More