Saertex, Safran sign agreement for carbon fiber aircraft equipment production

Under the 10-year contract, Saertex will supply multiaxial carbon fiber fabrics to Safran, to be used to produce engine nacelles for various aircraft.

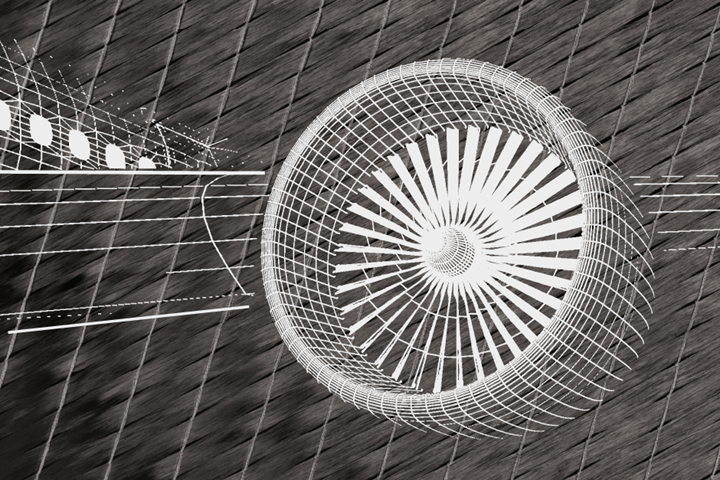

Photo Credit: Saertex

On August 27, Safran Nacelles (Burnley, U.K.) and Saertex GmbH (Saerbeck, Germany) signed a 10-year contract on cooperation for the production of aircraft equipment made of carbon fiber fabrics.

Under the contract, Saertex will supply multiaxial carbon fiber fabrics which Safran will use to produce engine nacelles for various aircraft using infusion technology. This contractual agreement means the cooperation of two globally operating companies.

"I am pleased that, with Safran, we have been able to convince an important new partner of our competence and improved technologies in the aerospace sector,” comments Christoph Geyer, CEO at Saetex at the contract’s conclusion. Similarly, Thierry Viguier, Safran vice president Materials Purchasing voices that Safran is excited for this new partnership.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.