ShapeTex preforms successfully overmolded with short fiber SMC

Shape Group successfully combines continuous carbon fiber preform with epoxy sheet molding compound using compression molding.

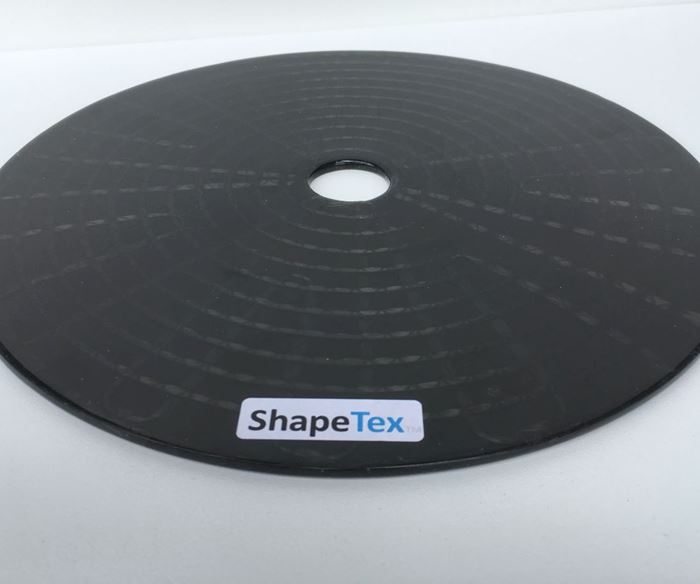

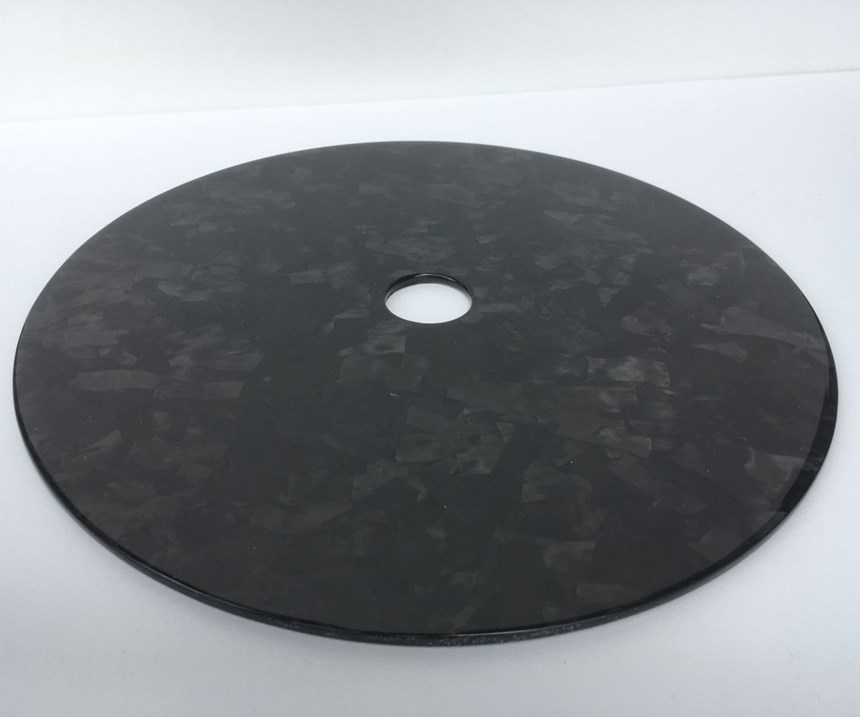

Shape Group (Witney, UK) has successfully compression molded the first batch of parts that combine short fiber sheet molding compound (SMC) over an optimized, continuous carbon fiber ShapeTex preform. This process is commonly referred to as overmolding. Typically, the overmold is an injection molded compound, but in this case ShapeTex used a compression molded SMC.

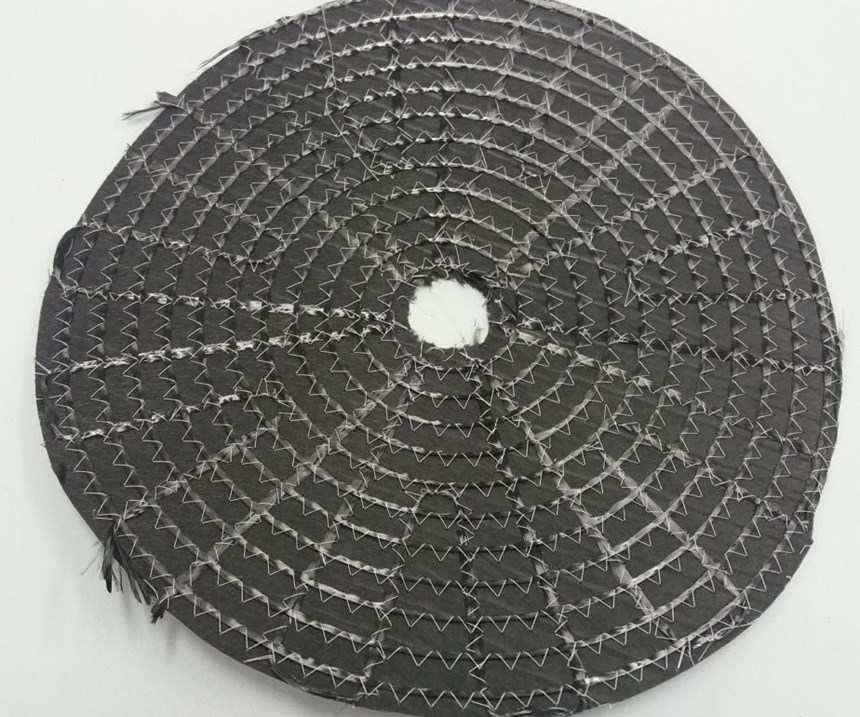

The ShapeTex preform uses a continuous tow of carbon fiber that gives significant strength to the finished part, including both radial and axial reinforcement. The short fiber SMC uses epoxy resin. The finished part is 4.5mm thick.

“The potential of this technology is quite significant,” McCool continues. “We have been working on this combination for quite a while and feel that now is the time to bring it to market. We have several customers that like the aesthetic look of the SMC and the ability to press and cure parts with channels, ribs and fixing bosses means that we can incorporate features into a single composite part that would otherwise require multiple operations and parts. This process has been developed using epoxy thermoset resins and offers closed molded parts with optimized strength using approved resin systems.”

Although these trials were conducted in a flat mold the process lends itself equally to complex and double curvature parts. Shape is targeting high volume applications in the automotive and sports equipment market with this process.

Related Content

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

.jpg;maxWidth=300;quality=90)