Siemens and Electroimpact highlight capabilities of SCRAM continuous fiber 3D printing system

The scalable robotic additive manufacturing (SCRAM) six-axis, continuous fiber 3D printing system combines multiple processes in one cell, powered by a Siemens control platform.

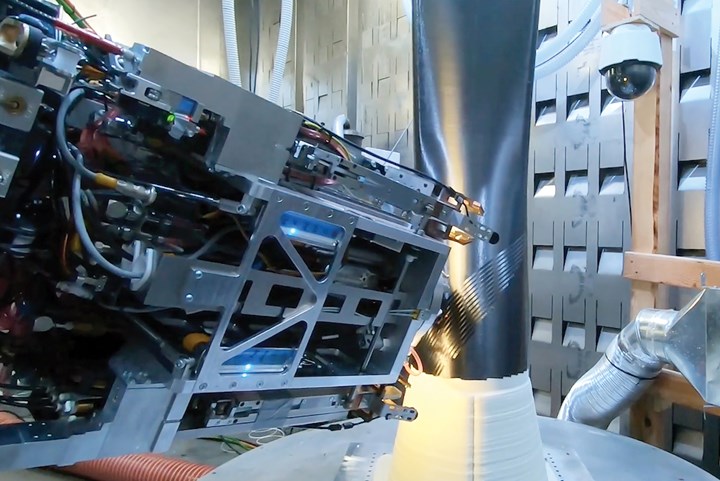

The SCRAM system, which is capable of performing several different manufacturing technologies — all in the same cell, all in one place, and all controlled by Sinumerik One from Siemens. Photo Credit: Siemens

In a recently published case study, Siemens (Elk Grove Village, Ill., U.S.) and Electroimpact (Mukilteo, Wash., U.S.) elaborate on the companies’ collaborative efforts and successes with Electroimpact’s scalable composite robotic additive manufacturing (SCRAM) system powered by Siemens’ Sinumerik One control platform.

SCRAM is an industrial, dix-axis continuous fiber-reinforced 3D printer that enables toolless, rapid fabrication of aerospace-grade, integrated composite structures. For this system, Electroimpat integrated an in-situ, out-of-autoclave (OOA), thermoplastic automated fiber placement (AFP) process, an advanced fused filament fabrication (FFF) 3D printing process, a fused granulate fabrication (FGF) 3D printing process and subtractive machining, all facilitated by the Sinumerik One control system.

According to the case study, looking towards the future, the companies aim for the Sinumerik One control platform to take the SCRAM into advanced digital twin technology. Digital twin technology will help teams engineer a fully functioning machine even before a real-life prototype exists and for teams to tansfer tasks from the real world to the virtual environment. Having Sinumerik One as a built-in tool will help reduce overhead costs for projects and support, Siemens says.

“There’s a huge industry push to having a digital twin,” says Kylie Martineau, Electroimpact controls engineer. “Being able to jump in and see what’s happening is so valuable. The digital twin capabilities of Sinumerik One will enable us to work extremely close to our customers in the future, supporting their desires to push the envelope of product development. With digital twin technology this accurate, customers will benefit from knowing we can jump in anytime to seamlessly help troubleshoot.”

Read Siemens’ full case study.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

.jpg;width=70;height=70;mode=crop)