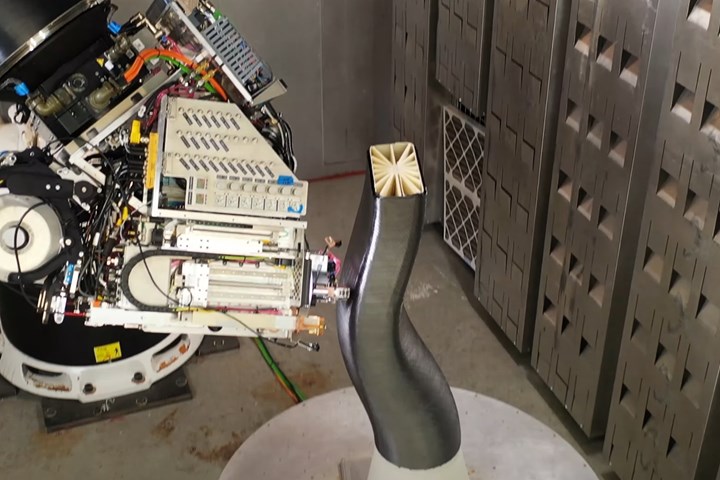

Electroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell

The Scalable Composite Robotic Additive Manufacturing (SCRAM) system 3D prints with continuous fiber tape or filament and seamlessly swaps end effectors for large-scale pellet deposition and CNC machining.

Source | Electroimpact

Electroimpact (Mukilteo, Wash., U.S.) has integrated an out-of-autoclave (OOA) in-situ consolidated thermoplastic automated fiber placement (AFP) process and an advanced fused filament fabrication (FFF) 3D printing process into a unified Scalable Composite Robotic Additive Manufacturing (SCRAM) system. SCRAM is a true 6-axis, industrial continuous fiber-reinforced 3D printer, which enables the tool-less rapid fabrication of aerospace-grade integrated composite structures. High-performance thermoplastics combined with a high percentage of continuous fiber reinforcement are used to produce parts with exceptional material properties previously unheard of in the world of additive manufacturing. Electroimpact asserts this technology has no equal in the industry.

“True 3D” printing

Most 3D printing processes are accurately described as “2.5D” printing, because material is deposited successively in flat slices, which are then stacked together to form a 3D object. The SCRAM process, however, can be considered “true 3D” printing because layers of continuous fiber-reinforced thermoplastic can take the shape of complex contours, such as aerodynamic surfaces and ducts for fluid flow. Furthermore, because it is a 6-axis process, fiber orientation within each layer can be tailored to the specific application to provide optimal strength and stiffness distribution throughout the part, much like a conventional AFP system.

Tooling printed on demand

Each SCRAM cell is equipped with not only a reinforced thermoplastic printing system – a scaled-down, more dexterous AFP with in-situ consolidation (ISC) – but also a rapid tool fabrication system based on an advanced FFF printing process. Conventional automated fiber layup requires a substantial investment in hard tooling that is inflexible, expensive and requires long-lead times. In contrast, SCRAM can simply print the support tool on demand, starting from just a flat plate. Later, after the part has finished printing, the tool material is dissolved away, enabling rapid design iterations. It also allows creation of part geometries such as internal channels that are difficult or impossible to produce via conventional means.

Multi-material system

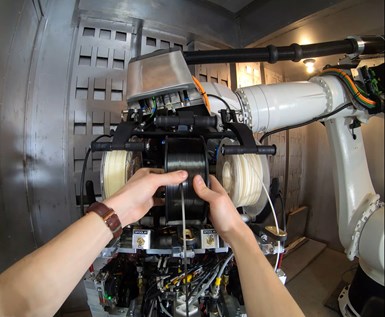

Loading of continuous carbon fiber-reinforced thermoplastic composite tape into Scalable Composite Robotic Additive Manufacturing (SCRAM) system. Source | Electroimpact

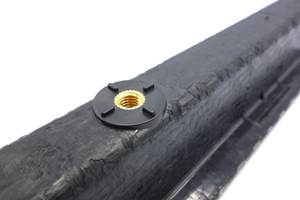

In addition to the continuous fiber-reinforced thermoplastic printing process (AFP ISC) and the FFF support tool printing process, SCRAM cells are also fitted with an FFF nozzle optimized for deposition of thermoplastic material reinforced with short or “chopped” fiber. A proprietary laser heating system is incorporated, producing exceptionally strong bonds between layers. This process is ideal for situations where laying up continuous fiber is geometrically impossible or otherwise doesn’t make sense.

Like the continuous fiber process, this is a “true 3D” printing process where the layers are not constrained to a stack of planes. Complex geometries such as variable-density core and other internal structures can be printed directly onto continuous fiber-reinforced layers with widely varying curvature. If desired, continuous fiber-reinforced layers can then be deposited on top of the chopped fiber-reinforced core structure, forming an upper skin. Example materials include:

- PAEK (polyarylketone) family thermoplastics (PEEK, PEKK, etc.)

- Nylons and other low-temp thermoplastics (PA12, ABS, etc.)

- Water-soluble thermoplastics

- Carbon fiber

- Glass fiber

- Boron fiber.

SCRAM cell configuration

Electroimpact’s SCRAM system uses a Siemens 840D CNC controller and 6-axis robot with its patented Accurate Robot package, including a continuous 6th robot axis for utilities pass-through with unlimited rotation. The tool change interface allows end effectors to be picked up and dropped off seamlessly including a multi-material deposition end effector.

The cell includes a heated build platform with rotating hot plate and is housed in a heated build chamber to control thermal expansion and shrinkage. SCRAM also comes standard with a coupon and calibration stand, CAM part programming software suite and training for operators, mechanics, and programmers.

Optional features include:

- High-throughput plastic pellet extrusion end effector, for depositing

large support tools quickly from inexpensive feedstock;

- Subtractive machining end effector, for trimming parts and conditioning support tool surfaces for optimal finish and accuracy;

- Partially reusable support tool system incorporating a water-soluble sacrificial layer for short production runs.

About Electroimpact

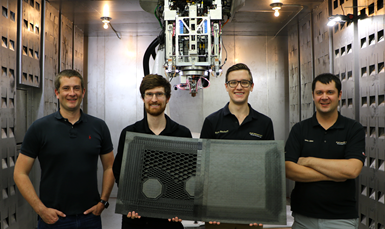

Scalable Composite Robotic Additive Manufacturing (SCRAM) system team includes (left to right) Cody Brown, Jordan Peterson, Ryan Bischoff and Reese Allen. Source | Electroimpact

Electroimpact is an experienced supplier of manufacturing automation and tooling to the aerospace industry. The company is a haven for engineers, who are vertically responsible for all work from concept to customer acceptance with minimal bureaucracy. Their projects include complete automation assembly systems for commercial aircraft wings, AFP (automated fiber placement) systems, high-accuracy robotic drilling and fastening machines, riveting machines for wing panel and fuselage assembly and spacecraft and satellite handling equipment.

Related Content

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More