SPE announces nomination call for Automotive Innovation Awards Gala

Winning part nominations are due Sept. 15., 2021 and will be presented at the gala. A new category, “Automotive Plastics Industry Solutions for COVID-19” has been added.

Shown above are members of the team that developed the 2019 Grand Award and Body Exterior category winner — the Composite Pickup Box on the 2020 GMC Sierra LD FST pickup from General Motors Co.

The Automotive Division of the Society of Plastics Engineers (SPE; Troy, Mich., U.S.) has announced a call for nominations for its 50th annual Automotive Innovation Awards Gala. This year’s Awards Gala will be held Wednesday, Nov. 10, 2021, at the Burton Manor in Livonia, Mich., U.S.

Winning part nominations (due by Sept. 15, 2021) in 11 different categories, and the teams that developed them, will be honored with a “Most Innovative Use of Plastics” award. A “Grand Award” will be presented to the winning team from all category award winners. This year’s program will also include a new category, “Automotive Plastics Industry Solutions for COVID-19,” to highlight how automotive OEMs and suppliers have adapted their processes, materials, or business to support the international needs for battling COVID-19. Additional categories include:

- Additive Manufacturing

- Aftermarket and Limited Edition/Specialty Vehicles

- Body Exterior

- Body Interior

- Chassis/Hardware

- Environmental

- Materials

- Powertrain

- Process/Assembly/Enabling Technologies

- Safety.

To further commemorate fifty years of plastics innovation, the Innovation Awards Gala planning committee has reported that it is working on special events to celebrate. One of the events will be a Hall of Fame (HOF) Award honoring the top five most innovative HOF winners since the category was established in 1983. Rather than pick one HOF winner for 2021, the HOF committee will determine the top 10 from the previous 38 winners, ranging from 1983 to 2019; the top five will be honored with special recognition at the event.

Criteria for a HOF award requires the innovation to be game changing; very successful worldwide; innovative in materials, process and application; and has been in continuous use for 15 years or more. The HOF committee consists of engineers, managers, executives, technical experts, SPE Fellows, SPE Honored Service Members and automotive industry technical experts having served at least 30 plus years in the industry. Nominations must be submitted online here.

“We’re really looking forward to celebrating a half century of automotive advancements enabled by innovative plastics technologies,” says Jeffrey Helms, global automotive director, Celanese Corp., who returns as the 2021 SPE Automotive Innovation Awards chair. “Unfortunately, we had to postpone the 2020 event due to CDC recommendations for social distancing as a result of the COVID-19 pandemic.

“However, this year, in addition to celebrating “50 Years of Plastics Innovation,” we will showcase how polymer technologies enabled solutions for battling COVID-19,” Helms continues. “Protective masks, face shields, clothing, medical supplies, ventilators and more are made possible or enhanced with plastics. Our society benefits from the ability of plastics to deliver form and function in unique ways through the creativity of automotive engineers and designers.”

The program will include advancements in safety, including seat belts, air bags and sensing devices, all enabled by advancements in plastics technology. The environmental benefits made possible with and by plastics, including improved fuel efficiency, reduced carbon emissions and the growth of automotive innovations with natural and recycled materials for improved sustainability will also be highlighted. Notable innovations in plastics enabled design and styling will also be honored.

During the competition phase of the event, dozens of teams made up of OEMs and suppliers will describe their part, system, or complete vehicle module to support claims that it is the year’s “Most Innovative Use of Plastics.” To win, teams must survive a pre-competition review and two rounds of presentations before industry and media judges.

There is no cost to nominate parts, however, nominations that are accepted into the competition need to be presented (in person or via webinar) by their nominating teams during the first round of Automotive Innovation Awards Competition judging, September 23-24, 2021 in Auburn Hills, Mich. Finalists from that round advance to a second presentation before a panel of Blue Ribbon judges made up of media, retired chief engineers, and other industry experts on Oct. 1, 2021 (also in Auburn Hills, Mich.) Winners of each part category, the Grand Award, Hall of Fame, and Lifetime Achievement winner will all be honored during the Automotive Innovation Awards Gala in November.

Related Content

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreRead Next

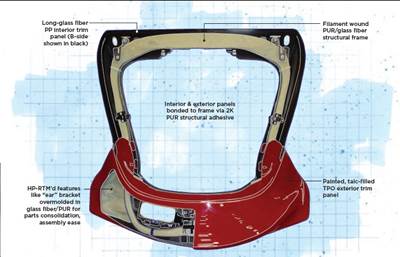

Liftgate design puts modified filament winding to the test

Heavily modified winding process produces light, structural support frame for performance-critical liftgate.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)