SPE Automotive Division names finalists for 52nd Automotive Innovation Awards

Finalists display a variety of plastics and composites innovations. Winners will be announced Nov. 8, 2023, during the 52nd SPE Automotive Innovation Awards Gala.

The Society of Plastics Engineers (SPE) Automotive Division (Troy, Mich., U.S.) has named the finalists for its 52nd annual Automotive Innovation Awards Gala. Nominations were first subjected to a pre-qualification review and then were presented before a panel of industry experts. That panel sent forward the most innovative nominations (category finalists) to the Blue Ribbon judging round. Category and Grand Award winners selected during the Blue Ribbon judging round will be announced on the evening of Nov. 8, 2023, during the 52nd SPE Automotive Innovation Awards Gala.

Since 1970, the SPE Automotive Innovation Awards Competition has highlighted the positive changes that polymeric materials have brought to automotive and ground transportation industries, such as weight and cost reduction, parts consolidation, increased safety, and improved aesthetics and design freedom. At the time the competition started, many OEM designers and engineers thought of plastics as inexpensive replacements for more “traditional” materials. To help communicate that plastics were capable of far more functionality than their typical use as decorative knobs and ashtrays indicated, members of the board of directors of SPE’s Automotive Division created the competition to recognize successful and innovative plastics applications and to communicate their benefits to OEMs, media and the public.

Finalists from this year’s competition are listed below in category and submission order.

Body Exterior

Flush sealing system.

Composite Cross-Members

- OEM Make & Model: 2022 Hyundai Motor Group Genesis GV70 and G80

- Tier Supplier/Processor: Sungwoo Hitech / Shinsung Composite Materials

- Material Supplier/Toolmaker: Hyosung Advanced Materials Corp. /Kukdo Chemical Co. Ltd./ NA

- Material/Process: KFR5121& KFH9581LV epoxy / injection box-based pultrusion

A novel hybrid pultrusion process can cost-effectively produce up to 20 million load-bearing and E-coat-capable structural composite beams annually thanks to a fully automated process. Beams provide the primary load path to pass IIHS side and pole impact tests, protecting occupants and on onboard battery packs while achieving a 30% increase in impact resistance versus roll-formed steel. An injection box added to the pultrusion line infuses high-performance epoxy into unidirectional carbon fiber and woven fiberglass reinforcement, reducing mass/vehicle by 12 kilograms and tool cost by 30% versus metallic benchmarks. Beams are attached to the body-in-white (BIW) via structural adhesives and blind rivets.

Flush Sealing System

- OEM Make & Model: 2024 NIO Ltd. NIO EC7, ES8, EC6 and ES6

- Tier Supplier/Processor: Cooper Standard

- Material Supplier/Toolmaker: Celanese Corp. and Shin-Etsu & EMS Grivory / Cooper Standard

- Material /Process: Santoprene 123-50W175 TPV and Exelast SX553 (TPO) and Grilon TSG-50/4 (PA66+PA6,GF50) rails: Co-extrusion with overmolding for finishing ends, sliders: Injection molding

This patented sealing system enables separation of the glass guidance rails/sliders from the weatherstrip/seal on framed doors, permitting improved aesthetics similar to frameless doors at lower mass, better noise/vibration/harshness (NVH), reduced complexity and faster assembly. The cost-neutral system also permits window regulators on framed doors and some competitive flush-glazing options to be converted from dual to single rails for both front and rear doors. A combination of injection molding and extrusion are used to produce the thermoplastic system, which maintains ±0.1 millimeter tolerances. Virtual validation technology was used to eliminate the need for physical prototypes.

Thermoplastic Splitgate

- OEM Make & Model: 2023 Rivian LLC Rivian R1S

- Tier Supplier/Processor: Magna International

- Material Supplier/Toolmaker: Advanced Composites Inc. / Tycos Tool & Die Co.

- Material/Process: LGF-PP and TPO / injection molding

This is reported to be the world’s first all-thermoplastic split gate rear-closure system, which is delivered to the assembly line as a ready-to-install module. The complex, deep draw (>80 millimeter) design offers improved perceived quality at lower mass, NVH and cost versus metals, and is offered in a two-tone execution. By commonizing grades between the liftgate and the benchgate and focusing on sustainability, parts were reduced from nine to three, and only two materials are used (injection molded LFT-PP and thermoplastic olefin/TPO). The CHMSL and tail lamps were carried over from the pickup model.

Uniformly Lit Animated Tail Lamps

- OEM Make & Model: 2023 General Motors Co. GMC Sierra and Chevrolet Silverado HD 2500/3500

- Tier Supplier/Processor: Magna Lighting

- Material Supplier/Toolmaker: Trinseo PLC / DBM Reflex

- Material /Process: Plexiglass V825-100 PMMA / injection molding

Key to the crisp and uniformly lit appearance of these animated taillamps are micro-optical features on injection molded light guides produced via a specialized manufacturing technique. Using an algorithm, the process starts by generating a pseudo-randomized topology that is machined into a master that is then used to create an electroform nickel insert. The technology produces a smooth appearance with far fewer LEDs, eliminates hot spots from point light sources and permits crisper animation in tighter packaging depths versus traditional approaches.

Electric & Autonomous Vehicle Systems

Battery disconnect unit.

Battery Disconnect Unit

- OEM Make & Model: 2023 General Motors Co. GMC Hummer EV

- Tier Supplier/Processor: Lear Corp.

- Material Supplier/Toolmaker: BASF Corp. / Lear Corp.

- Material /Process: Ultramid 66 H2 G25 V0KB1 and Ultradur B4450G5 HR / injection molding

Two BDUs have been integrated into a single system supporting two 400-volt systems, which enable fast and safe recharging of electric vehicles (EVs) and disconnects power in an over-current situation to protect passengers. The meter-long parts feature a complex design that offers improved thermal management and reduced component mass. Two UL94 V0 halogen-free materials — one with very high CTI — replaced die-cast aluminum while maintaining improved physical properties and ease of processing. Complex simulation and process optimization were also key to success.

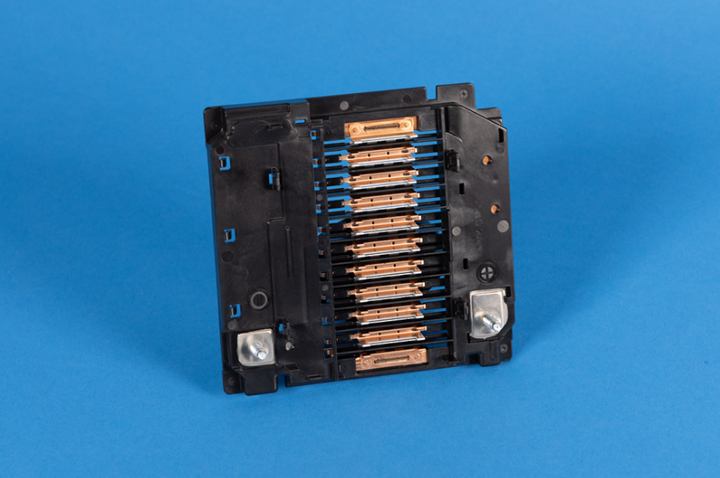

Interconnect Board

- OEM Make & Model: 2023 General Motors Co. Cadillac Lyriq and GMC Hummer EV

- Tier Supplier/Processor: Korea Electric Terminal Co. Ltd.

- Material Supplier/Toolmaker: LG Chem Ltd./ NA

- Material /Process: Lumid GN2251BF PA66-GF25 / injection molding

This patented interconnect board (ICB) design supports, cools and isolates cell tabs/busbars, provides support and structure to the module between the top cover and cold plates and aids assembly by guiding, supporting and constraining cell tabs. The overmolded busbar design, which reduces copper use by approximately 25%, enables cooling through the frames from the cold plate. Honeycomb and rib features on the back reduce mass, increase clearance to cells, improving structure, especially during critical manufacturing processes, and contribute to finger-proofing requirements. Additionally, the hinged ICB ships flat, reducing shipping space by 78%, then folds for assembly.

Battery Module Component

- OEM Make & Model: 2023 Hyundai Motor Group Ioniq 6

- Tier Supplier/Processor: Hyundai Mobis Co. Ltd./ Infac Corp.

- Material Supplier/Toolmaker: SABIC Korea / NA

- Material /Process: SABIC PPc H1030 PP-SGF30 / injection molding

Use of a 30% GR/PP material with intumescent fire-retardant (FR) package reduces weight 10% and cost 20% while improving fire safety versus FR 30% GR/PA6. This is also the first thermoplastic to pass China’s GB/T 41467.3-2015 fire safety regulation for EVs surviving 5 minutes at 1,000°C. Improved flow properties versus PA6 permitted higher cavitation tooling to be used, doubling productivity in the same cycle time, while also lowering molding temperatures for energy and CO2 improvements. Versus metals, mass reduction of 18 kilograms/vehicle is achieved. The design also features an integral overmolded busbar.

Processing/Assembly/Enabling Technology

Console structural carrier tooling.

Seat Module

- OEM Make & Model: 2024 Toyota Motor Corp. Toyota Grand Highlander

- Tier Supplier/Processor: Hi-Lex Corp.

- Material Supplier/Toolmaker: NA / Hi-Lex Corp.

- Material/Process: NA / injection molding

This patented injection molded module for seats incorporates both temporary and permanent holding features to control cables and dramatically reduce both components and labor at the seat manufacturer. Cables are delivered to the Tier 1 pre-routed on the module plate, eliminating the brackets, cable ties and clips typically used to control seat cables, and greatly reducing labor for an assembly operator. The module also reduces rework and scrap due to cable misalignments. Additionally, lever pull effort for consumers is reduced because direct cable routing enables use of shorter cables.

Laser Welded xEV Spray Bars

- OEM Make & Model: 2023 Ford Motor Co. Ford Edge

- Tier Supplier/Processor: Nifco America Corp. / NA

- Material Supplier/Toolmaker: Celanese Corp. / NA

- Material /Process: Zytel 45HSB PA 6/6 / injection molding and laser welding

Moving from drilled metal to molded plastic tubes on spray bars can reduce mass and cost and reduce contamination concerns involving the presence of metal shavings from drilling operations. To create an enclosed structure with the holes needed to spray fluid via injection molding, parts must be molded in two complex, contoured halves and joined. The cleanest joining process proved to be laser welding. The high-flow, heat-stabilized PA6/6 grade was selected for its high thermal resistance, low contamination, consistent quality and resistance to automatic transmission fluid.

Compressor Housing

- OEM Make & Model: 2022 General Motors Co. Cruise Origin

- Tier Supplier/Processor: HP Inc. & Carbon Inc. / GKN Additive (Forecast3D)

- Material Supplier/Toolmaker: HP Inc. & Carbon Inc./NA

- Material /Process: HP PA12 HR and Carbon EPX82 epoxy / HP MJF 5100 Series + Carbon M2

To meet application specifications and tight timing requirements, two different polymer additive manufacturing processes (MJF and SLA) and two different polymers (PA12 and epoxy) were combined to produce the compressor housing for this low-volume, autonomous vehicle. MJF offered high throughput and cost effectiveness for the bulk of the compressor housing while SLA offered higher dimensional tolerances and smoother surface finish on the connector, which facilitated passing USCAR push/pull requirements. By using each process’ strength and bonding parts together, cost and performance were optimized, tooling was eliminated and program delays were avoided.

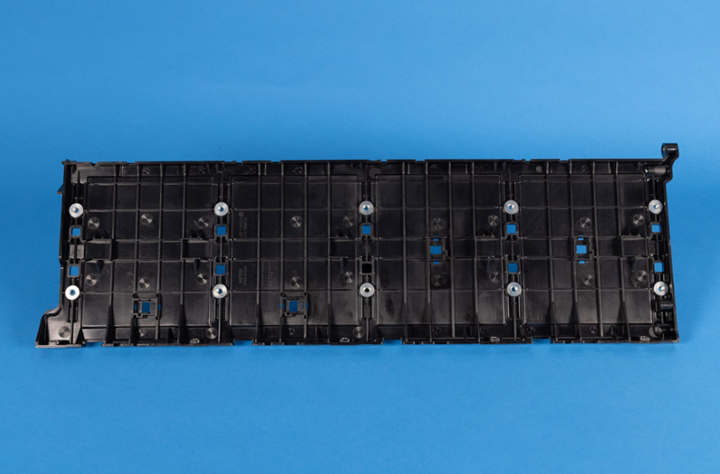

Battery Module Structure

- OEM Make & Model: 2024 General Motors Co. Chevrolet Corvette E-Ray

- Tier Supplier/Processor: General Motors Co. / Novares Group

- Material Supplier/Toolmaker: RTP Co. and Solvay SA / Liberty Molds Inc.

- Material /Process: RTP 299 KX133837E Para and Amodel A-1145 HS BK 324 PPA / injection molding

This all-thermoplastic battery structure combines two side plates and 45 repeating spacers bolted together to hold pouch-style batteries. The patented, volumetrically efficient design withstands high cell expansion forces during battery use while eliminating the need for 55 compression limiters plus isolation countermeasures necessary with metals. Side plates are injection molded with 50% GR/Para while spacers are injection molded with 45% GR/PPA. Both materials required high molding precision, dimensional accuracy, flame retardance and the ability to integrate a variety of functional features that facilitate assembly. Versus aluminum, both mass and cost are reduced.

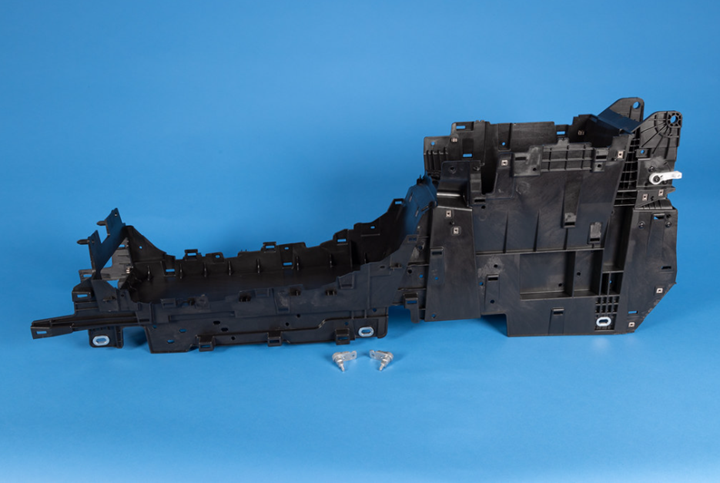

Console Structural Carrier Tooling

- OEM Make & Model: 2024 General Motors Co. Cadillac Lyriq

- Tier Supplier/Processor: ABC Technologies Inc.

- Material Supplier/Toolmaker: Celanese Corp. / Integrity Tool and Mold Inc.

- Material/Process: Celstran PP-GF40-0453 (40% LFT PP) / injection molding

Tight packaging space and the space for an HVAC outlet in the console meant a traditional through-pin-type hinge could not be used on the armrest to keep it latched during a crash. A friction hinge with inertial lock — previously only used in the furniture industry — solved the problem, but required unique tooling innovation to be feasible. The triple-action, two-stage slide featuring a horn-pin driven slide with collapsible lifters on top of a hydraulic main bottom slide was developed, enabling direct edge gating on top of the slide to optimize filling conditions.

Sustainability

Eco-friendly cable control.

Basalt Fiber-Reinforced ADAS Bracket

- OEM Make & Model: 2024 Ford Motor Co. Ford F-150

- Tier Supplier/Processor: Yazaki Corp. / HellermannTyton

- Material Supplier/Toolmaker: The Materials Group / HS Mold Ltd.

- Material/Process: Optilon N6-30B HSBK 30% basalt fiber-reinforced PA6 / injection molding

By replacing E-glass with basalt fiber in this injection molded ADAS bracket, which also contained 60% PIR PA6, cost and weight were neutral, the part met all performance requirements, no tooling changes were needed, but a CO2 reduction of 74% was achieved and 180,000 kilograms of material annually is kept from landfills. The drop-in change is more sustainable, addresses issues with glass shortage and provides the same performance as virgin material.

Bracket from Recycled BMC

- OEM Make & Model: 2023 General Motors Co. Chevrolet Silverado LD

- Tier Supplier/Processor: Valeo Lighting Systems / Techniplas

- Material Supplier/Toolmaker: LyondellBasell / Chicago Mold Engineering Co. Inc.

- Material/Process: Dura 304 UP BMC / injection molding

Replacing magnesium with unsaturated polyester BMC yielded structural brackets meeting high dimensional requirements at comparable or improved mechanical performance — especially toughness. The bracket was made more sustainable with inclusion of 6% PIR PMMA and 5% PIR BMC scrap, which replaced calcium carbonate filler. It took 2 years of work to develop the process to recover and reclaim thermoset BMC scrap and reuse it in new parts with a lower CO2 footprint. Key to the success of the program were grinding, sizing and formulation strategies. No tooling changes were required versus virgin BMC.

One-Piece Thermoplastic Frunk

- OEM Make & Model: 2024 Ford Motor Co. Ford Mustang Mach E

- Tier Supplier/Processor: IAC Group

- Material Supplier/Toolmaker: Advanced Composites Inc. / HS Inc.

- Material/Process: ADX8327 20% PCR TPO / injection molding

This is the first time a 20% PCR recycled material has been used in a color-matched, MIC, Class A structural funk application. Versus virgin TPO, the more sustainable grade lowered density slightly and offered better impact at -15°C. Concurrent redesign reduced component count from six to one, including eliminating two metal brackets, saving 3 kilograms of mass, increasing cargo volume and functionality, improving water management, reducing cost and labor and saving an estimated 1,125 tons of CO2 annually. PCR content is sourced from yogurt cups and packaging materials.

Eco-Friendly Cable Control

- OEM Make & Model: 2024 Ford Motor Co. Ford Mustang

- Tier Supplier/Processor: Aptiv PLC / HellermannTyton

- Material Supplier/Toolmaker: Ascend Performance Materials / NA

- Material/Process: Redefyne IAI2H BK0858 PA66 / injection molding

This is reported to be the first broad-scale shift from virgin to PIR PA66 in cable management parts, a drop-in-change offering comparable performance, aesthetics and processing at lower cost and 35% lower carbon footprint without any part design or tooling changes. Although the parts are small, they are produced in high-cavitation injection tooling and offer best-in-class mechanical, thermal and chemical performance. In just the first year, the change removed 138,000 kilograms of CO2 and saved 70,000 kilograms of coal and 144 billion barrels of crude oil from being used.

Related Content

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreRead Next

SPE ACCE 2023 provides combination of presentations, exhibits, networking

The event featured exhibits, speakers, an awards ceremony for scholarships and more.

Read MoreSPE announces 2023 Lifetime Achievement Award winner

Kevin Pageau, owner and president of International Marketing Alliance, and a major contributor to the SPE Automotive Division Lifetime Awards Program, will be honored at the awards gala on Nov. 8.

Read MoreChevrolet Corvette E-Ray wins 2023 Vehicle Engineering Team Award

Numerous plastic and composite technologies are featured on the 2024 vehicle recognized by the SPE Automotive Division.

Read More

.jpg;maxWidth=300;quality=90)