Stellantis to build Midnight eVTOL aircraft with Archer

Stellantis is to contribute advanced manufacturing technology and expertise, experienced personnel and capital, in addition to help stand up Archer’s new composites manufacturing facility, with the ultimate goal of becoming Archer’s exclusive contract manufacturer.

Share

Read Next

On Jan. 4, Stellantis N.V. (Amsterdam, Netherlands) and Archer Aviation Inc. (Santa Clara, Calif., U.S.) announced a significant partnership expansion by joining forces to manufacture Archer’s flagship electric vertical takeoff and landing (eVTOL) aircraft, Midnight.

Stellantis will work with Archer to stand up Archer’s recently announced composites manufacturing facility in Covington, Ga., U.S., at which the companies plan to begin manufacturing the Midnight aircraft in 2024. Midnight is designed to be safe, sustainable, quiet and, with its expected payload of more than 1,000 pounds, can carry four passengers plus a pilot. With a range of 100 miles, Midnight is optimized for back-to-back short distance trips of around 20 miles, with a charging time of approximately 10 minutes in between.

The aircraft’s the primary structure (fuselage, wings, tail, rotors, propellers) will be fabricated with composite materials. A low-rate initial production (LRIP) facility will be built in San Jose, Calif., of this year for low-volume manufacture of Midnight, Archer told CW. Once the Covington, Ga., facility is complete, manufacturing operations will be transferred there.

This unique partnership in the urban air mobility (UAM) industry will leverage each company’s respective strengths and competencies to bring the Midnight aircraft to market. Archer says it brings its world-class team of eVTOL, electric powertrain and certification experts while Stellantis will contribute advanced manufacturing technology and expertise, experienced personnel and capital to the partnership. In relation to composites, Archer’s team is directly responsible for sourcing materials, while Stellantis will be providing input to ensure suitability for mass manufacturing. Ultimately, this combination is intended to enable the rapid scaling of aircraft production to meet Archer’s commercialization plans, while enabling Archer to strengthen its path to commercialization by helping it avoid hundreds of millions of dollars of spending during the manufacturing ramp-up phase. The goal is for Stellantis to mass produce Archer’s eVTOL aircraft as its exclusive contract manufacturer.

Stellantis said, in response to a CW query about manufacturing industrialization of Archer’s Midnight aircraft, “Stellantis has been working closely with Archer for the past two years and believes that the combination of skills and competencies of both companies, including Stellantis’ deep manufacturing expertise, will enable the rapid scaling of aircraft production to meet Archer’s commercialization plans. Stellantis will bring any applicable manufacturing technology that it has utilized to achieve its own high-volume production in the automotive industry. Keep in mind that Stellantis manufactures over 500,000 vehicles per month around the world, with 4,000 parts per car. Therefore, we strongly believe that we can contribute significantly to Archer in terms of world-class, mass-scale manufacturing and supply chain expertise.”

As a further sign of its commitment, Stellantis will provide up to $150 million in equity capital for potential draw by Archer at its discretion in 2023 and 2024, subject to achievement of certain business milestones which Archer expects to occur in 2023. Stellantis also intends to increase its strategic shareholding through future purchases of Archer stock in the open market. These actions, along with the other elements of this expanded partnership, will enable Stellantis to become a long-term, cornerstone investor in Archer.

“We’ve been working closely with Archer for the past two years, and I am continually impressed by their ingenuity and unwavering commitment to deliver,” Carlos Tavares, Stellantis CEO, says. “Deepening our partnership with Archer as a strategic investor with plans for growing our shareholding demonstrates how Stellantis is pushing the boundaries to provide sustainable freedom of mobility, from the road to the sky. Supporting Archer with our manufacturing expertise is another example of how Stellantis will lead the way the world moves.”

Stellantis has been a strategic partner to Archer since 2020 through various collaboration initiatives, and as an investor since 2021. During this time, Archer has leveraged Stellantis’ deep manufacturing, supply chain and design expertise in connection with Archer’s efforts to design, develop and commercialize its composite eVTOL aircraft.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

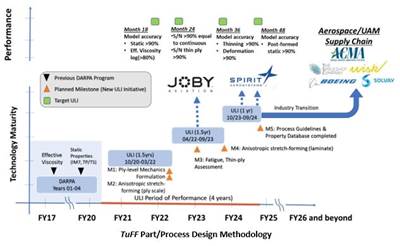

UD’s Center for Composite Materials hosts NASA University Leadership Initiative

October meeting of industry, government and academic accentuates the University of Delaware’s study of research and technology barriers in UAM using its new class of composite materials, TuFF.

Read MoreNorco to build fuselage, wings and composite components for Skyfly eVTOL aircraft

Skyfly aims to achieve a complete airframe weight of just 220 kilograms, in addition to low-cost, accurate and reliable repeatability of manufacture for series production progression.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)