Teton Simulation introduces new AM simulation tool for BCN3D Stratos software

SmartSlice for BCN3D Stratos features sophisticated print parameter optimization to eliminate costly print-test-redesign cycles and ensure printed parts perform as expected.

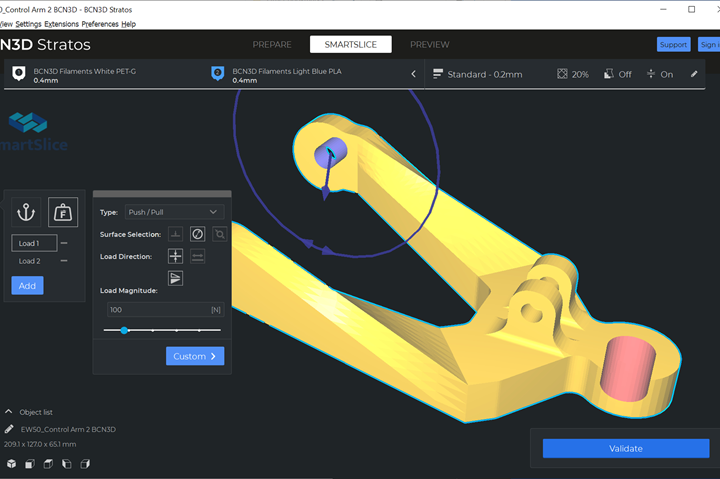

Photo Credit: Teton Simualtion

Teton Simulation (Laramie, Wyo., U.S.) a provider of 3D printing simulation software, has announced SmartSlice, its simulation tool for 3D printing for plastics and polymers, for BCN3D Stratos (Barcelona, Spain) 3D printing slicing software, which enables BCN3D users to validate and optimize their designs for additive manufacturing.

According to Teton, the SmartSlice workflow begins with the selection of material and baseline print settings and the definition of requirements for part performance. SmartSlice then validates the design, after which the user can manually run tests for different materials and settings, or use the SmartSlice optimization tool to minimize print time and material use.

One of the defining features of SmartSlice for BCN3D Stratos, Teton says, is the ability to make smart decisions determining print parameters, optimizing them for performance demands and manufacturing efficiency to reduce print time and material use. Ultimately, that means users will obtain a higher ROI on their projects by saving time and print-break cycles and will use less material. While savings vary depending on the part and use case, Teton claims the average SmartSlice user reports 30%+ reductions in print time and material usage.

The SmartSlice materials database supports a variety of BCN3D filaments, allowing users to virtually qualify a material for structural applications prior to purchase. SmartSlice can validate the as-printed performance of a part, enabling the user to evaluate whether it’s under- or over-designed by comparing simulated part deflection and safety factors to limits they define.

“In conjunction with our partner, BCN3D, Teton will now be extending its product line to include BCN3D Stratos,” says Teton Simulation CEO Doug Kenik. “Now users can minimize print time, remove unnecessary print cycles and reduce material usage — all while ensuring parts will perform as expected directly within BCN3D Stratos. SmartSlice will be pre-installed within BCN3D Stratos and will automatically grant a free trial to anyone with a BCN3D account.”

Related Content

-

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

.jpg;maxWidth=300;quality=90)