Toray reveals glass fiber-reinforced PPS recycling technology

Proprietary compounding process achieves recycled GFRP-PPS pellets offering comparable mechanical strength performance to virgin products.

Photo Credit, all images: Toray Industries

Toray Industries Inc. (Toyko, Japan) announces that it has developed a technology that makes it possible to recycle glass fiber-reinforced

polyphenylene sulfide (GFRP-PPS) that performs like virgin resins. The increased recycling ratio also contributes to emission reduction.

PPS resin is an engineering plastic with optimized heat and chemical resistance. More than 90% of PPS resin is glass fiber-reinforced and can be applied to various types of industrial applications. PPS resin also features good insulation resistance, making it well suited for electronic parts such as semiconductors and electric vehicle parts.

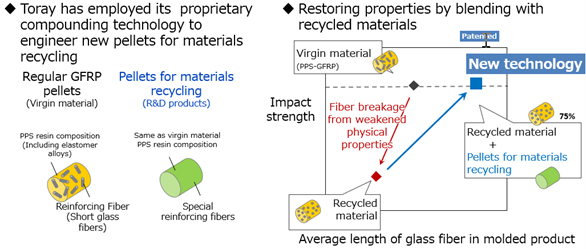

According to Toray, the conventional process for recycling GFRP-PPS shortens glass fibers and break them, decreasing mechanical strength. To combat this, Toray has developed pellets for recycling materials by leveraging a proprietary compounding technology to blend PPS resin with special reinforcing fibers. It enables comparable mechanical strength performance to virgin products. This is still the case, even when the recycled material accounts for 50% or more of the GFRP-PPS material. CO2 emissions are also reduced by at least 40%.

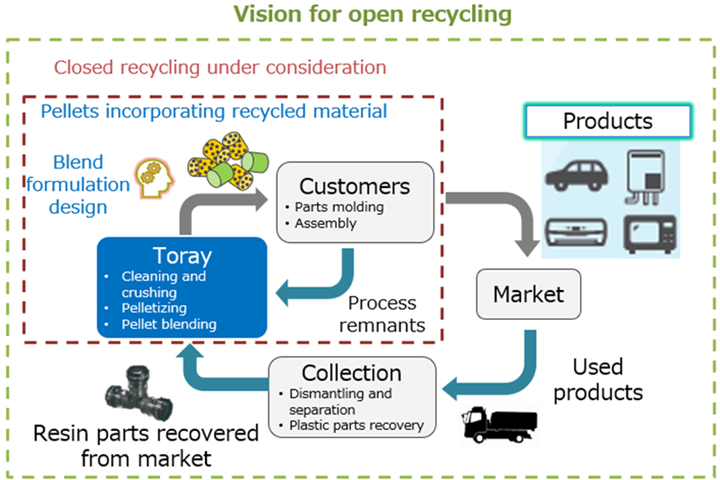

The company is working on technologies to broaden its variations by designing different resins and additives in pellet form for recycling materials. Collaborating with several molding companies and other business partners, Toray has already embarked on closed recycling initiatives with its technology. One move has been to supply customers with recycled GFRP-PPS pellets blended with those for materials recycling based on process remnants from customer plants. The company is also conducting tests to verify horizontal recycling and to prepare for commercialization with cooperation from customers.

Toray plans to seek more partners to create a recycling program and will foster the use in open recycling for materials recovered from the marketplace. A first step will be to develop sample work, primarily for customers in Japan, and from there launch offerings under Ecouse, Toray’s integrated brand for recycled materials and products.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

.jpg;maxWidth=300;quality=90)