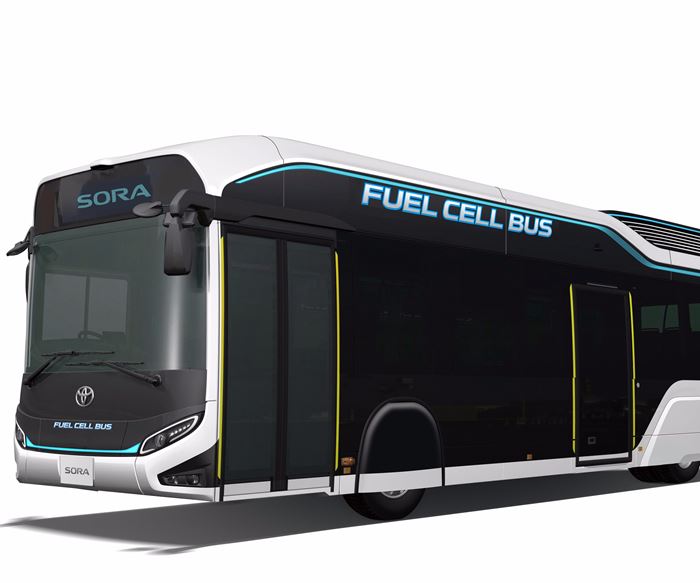

Toyota fuel cell bus features carbon fiber composite roof

Toho Tenax carbon fiber and aluminum are combined in fabrication of roof for Toyota hydrogen-powered bus.

Toho Tenax Co. Ltd. (Tokyo, Japan) the core company of the Teijin Group’s carbon fiber and composites business, announced on Nov. 2 that it has developed a lightweight multi- material roof cover for a fuel-cell-powered bus made of carbon fiber composites, aluminum and other lightweight engineering plastics. The roof cover, which boasts a visually appealing surface, is manufactured in one piece with complex shapes and is suitable for mass production.

The roof cover is being applied to the world’s first mass-produced, fuel-cell-powered bus, which was developed by Toyota Motor Corp. Since the bus carries high-pressure hydrogen gas tanks in its upper structure, lightweight body components in the top part of the vehicle are crucial.

Toho Tenax collaborated with GH Craft Ltd., the Teijin Group’s composite structure design, development and evaluation unit, to develop the multi-material roof by leveraging Toho Tenax’s high-performance carbon fiber and mass-production know-how and GH Craft’s molding technology.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.