TPI, UMaine, ORNL to leverage world’s largest polymer 3D printer for wind turbine tooling

Ingersoll Masterprint LFAM printer will be used to produce and demonstrate 100% recyclable tooling that could cut large composite blade development cycles and tooling costs by as much as 50%.

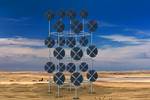

In late May 2024, UMaine announced that it broke its own 2019 Guinness World Record for the largest polymer 3D printer, with the introduction of the Ingersoll “Factory of the Future 1.0,” shown here. Source | University of Maine’s Advanced Structures and Composites Center (UMaine ASCC)

TPI Composites Inc. (TPI, Scottsdale, Ariz., U.S.) is partnering with the University of Maine’s Advanced Structures and Composites Center (UMaine ASCC, Oreno, U.S.) and Oak Ridge National Laboratory (Oak Ridge, Tenn., U.S.) to use UMaine’s Ingersoll (Rockford, Ill., U.S.) MasterPrint, one of the world’s largest 3D printers, for the production of wind turbine tooling. The goal of this project is to understand how new technologies can provide faster, lower cost precision manufacturing of large, modular wind blade tooling.

The ASCC’s polymer 3D printer can print modular wind blade tooling at 500 pounds/hour, with segments up to 18.3 meters long × 6.7 meters wide × 3.0 meters high. With a five-axis machining head, the printer can achieve 5-mil precision, enabling tooling segments to be joined, to maintain vacuum integrity and to provide the dimensional accuracy demanded in wind blade manufacturing. As part of the project, the tooling will also incorporate 3D printed heating elements using co-extruded resistive wire to achieve uniform mold temperatures within 5°C and heating rates of 0.5°C per minute.

As an important part of this program, TPI will use the section of full-scale tooling to fabricate actual composite components from the printed tooling assembly, which will be composed of assembled modules. Demonstration of this technology aim to enable lower cost transportation and rapid assembly of multi-megawatt scale wind blade molding systems globally.

“TPI Composites has a long-standing commitment to developing cutting-edge solutions for the wind energy industry,” notes Bill Siwek, president and CEO of TPI Composites. “By leveraging 3D printing technology, we are looking at ways to streamline our tooling process and pave the way for more efficient and cost-effective wind blade production.”

ASCC’s executive director, Habib Dagher says that they have “partnered with over 500 companies worldwide to drive advances in composite structures for the marine, defense, housing, renewable energy, and transportation industries. The 6.7-meter-width of our Ingersoll MasterPrint machine exceeds the chord width of modern wind blades, enabling us to conduct full-scale R&D applying large-scale additive manufacturing to wind blade production.”

The tooling will be 100% recyclable and may reduce large blade product development cycles and tooling costs by as much as 50%. The partners agree that 3D printing offers a more environmentally friendly approach to tooling fabrication, minimizing resource consumption and overall production footprint.

Related Content

-

Hexagon Purus opens new U.S. facility to manufacture composite hydrogen tanks

CW attends the opening of Westminster, Maryland, site and shares the company’s history, vision and leading role in H2 storage systems.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

.jpg;maxWidth=300;quality=90)