Update: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Share

Read Next

This blog is an in-depth look at what THOR has achieved and its lessons learned for future hydrogen storage tanks to be made from thermoplastic composites (TPC).

Started in 2019 and completed in September 2022, the Thermoplastic Hydrogen tanks Optimized and Recyclable, or THOR project, was funded by the Fuel Cells and Hydrogen 2 Joint Undertaking (FCH2JU) now Clean Hydrogen Partnership. Its goal was to develop an industrializable and recyclable TPC pressure vessel for hydrogen (H2) storage onboard vehicles and also in multi-tank modules for distribution/transportation of H2.

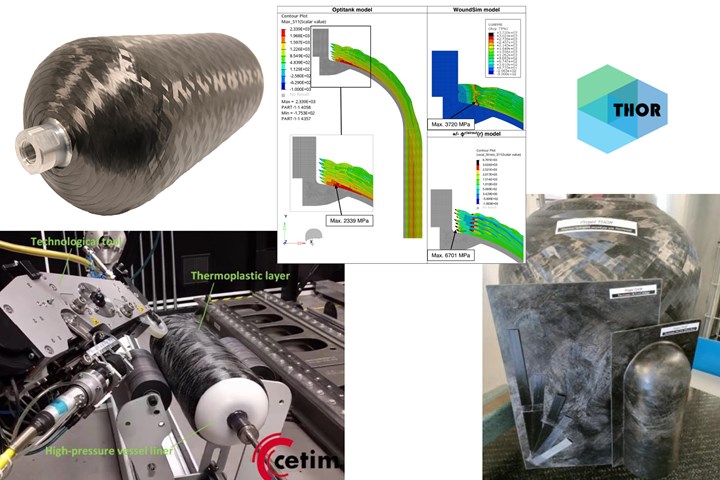

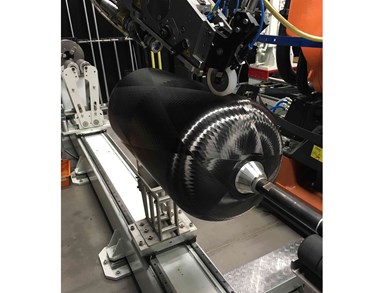

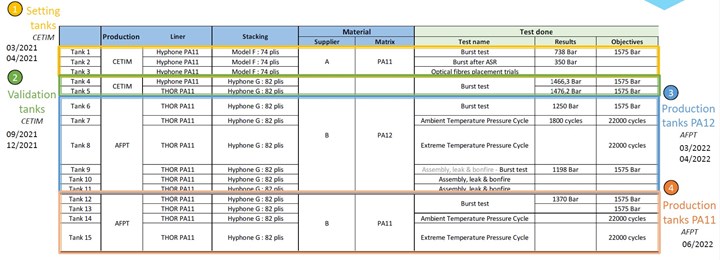

All such current storage solutions are made using thermoset composites. The THOR project produced 15 TPC tanks in collaboration with AFPT (Dörth, Germany), a supplier of laser-assisted tape winding (LATW) technology and equipment. These included tanks that held up to burst pressures of approximately 1,500 bar, just 6% short of the 1,580 bar required per the EC79 qualification standard.

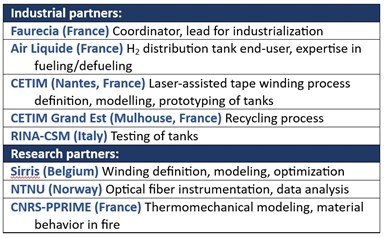

Project partners, Cetim’s role

The THOR project was led by Faurecia (Nanterre, France) a longtime automotive Tier 1 that is now part of the Forvia Group, reported to be the world’s seventh largest automotive supplier. Faurecia has developed a range of H2 storage and drivetrain systems for cars, commercial vehicles and heavy trucks and started mass production at its 47,000-square-meter plant in Allenjoie, France, which has a capacity of 100,000 Type 4 tanks/year. Other THOR projects partners are shown at right.

Cetim (Senlis, France) was also a key partner. This technical center for mechanical industry has more than 120 people working in polymers and composites in two key sites: Bouguenais, at the Composites Technocampus near Nantes, and Mulhouse in Great Est of France. Cetim Grand Est was the original partner in THOR, assigned the work package to demonstrate recycling of TPC tanks using its Thermosaïc technology.

However, when the THOR project had to restart mid-term due to withdrawal of original tank manufacturing partner Covess (Hasselt, Belgium), Cetim Bouguenais/Nantes was brought in to work with Faurecia and help Sirris adjust its TPC tank design to work with Cetim’s LATW technology called Spide TP. Within 18 months, the team completed production and testing of demonstrator tanks.

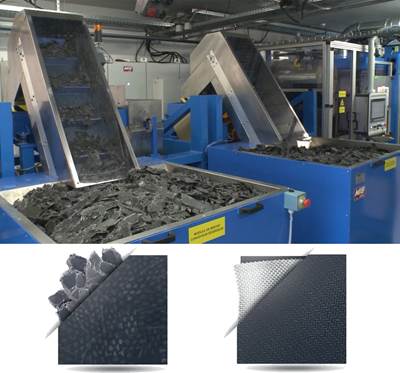

THOR project manufacturing of thermplastic composite pressure vessels at Cetim. Source | THOR project.

“We started developing our Spide TP technology 10 years ago,” says Clément Callens, head of Polymers and Composites Engineering Department at Cetim. “We had already been working with TPC tape manufacturers, for example, to study tape quality and its impact for our process. But then we started seeing industrial companies wanted to use tape winding to develop H2 storage tanks. Now, the TPC tape suppliers want to make sure they are developing materials that can be used to make H2 tanks in the future. This has been a big area of development for several years now.”

The TPC tank baseline for THOR was based on a Faurecia state-of-the-art Type 4 thermoset composite tank with a nominal working pressure (NWP) of 700 bar and water volume of 63 liters. It featured a rotomolded liner made with PA11 polymer from Arkema (Colombes, France) overwound with T700 carbon fiber from Toray (Tokyo, Japan) using epoxy resin in a traditional wet filament winding process. THOR’s tank, however, would need to be redesigned to use TPC tape.

Where Covess used a tape winding process using an infrared heater, Cetim’s process used a laser and achieved in-situ consolidation where no further vacuum bagging, oven or autoclave process is required. The demonstrator tanks made using this process were then tested to validate the feasibility of this technology to meet industry requirements and enable mass production as well as recycling at end of life (EOL).

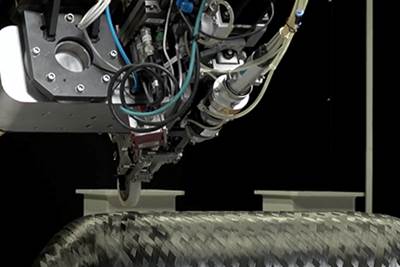

Spide TP process

This is an automated tape winding process developed with AFPT, says Callens. The original system used a KUKA (Augusburg, Germany) KR210 R3100 robot with a linear rail and a tape winding head from AFPT equipped with a 4-kilowatt laser that can apply TPC tape up to 25.4 millimeters wide. The system also had two external axes for winding — a smaller axis up to 3.5-meters long and a larger axis up to 6 meters long. The process begins with a mandrel or tank liner mounted into one of the rotating axes. The robot then places heated tape along desired paths to create the composite laminate. As the heated tape is placed, a compaction roller applies pressure which removes air and achieves consolidation.

Callens notes this technology was developed for a variety of markets. “Pressure vessels is one market, but there are many others for tubes and pipes,” he notes. “We also won a JEC award in 2023 using the process to make a Kreuger flap for aircraft wings in the Clean Sky 2 project SWING.” For these flaps, Cetim applied tape comprising carbon fiber-reinforced low-melt polyareletherketone (LMPAEK) polymer from Victrex (Cleveleys, U.K.). “We were able to place 1-5 kilograms/hour,” notes Callens. “With in-situ consolidation, the product is finished at the end of winding. You don't have to put the part in an oven or autoclave, which means significant savings in manufacturing cycle times and costs.”

As explained in a 2018 CW feature on in-situ consolidation, structures of revolution such as pipes, tubes and pressure vessels, were the first parts to be made of thermoplastic composites, dating back to the 1980s. The tension during winding helps to consolidate the laminate. “We have the tension for stability but most importantly, the pressure from the compaction roller applied to the tapes just after the in-situ welding and during the whole layup process,” adds Callens.

“We have proved we can make good laminates with low porosity and sufficient crystallinity for high mechanical properties,” he continues. “However, there was still work to be done to be fast enough to have reasonable costs because the TPC tapes are more expensive than the materials used with wet filament winding. And that’s a topic we are now covering as we have invested in a second tape winding line, again with AFPT, featuring an optimized head for the laser and tape application to be very fast, specifically for repeatable hydrogen tank production with a good industrial cost.”

“This new equipment is part of the 25M€ of investment of our major HyMEET program launched in 2022 to provide consultancy, support and training services to all manufacturers,” he adds, “to help them adjust their products and equipment to the requirements of hydrogen in its its gaseous and liquid forms.

Type 4.5 or 4+ tanks

“Cetim was not really at the beginning of the project, but I think the idea was to go for Type 5 tanks,” says Callens. “In our experience, when using thermoplastic composites, we believe you can achieve a tank that is in between Type 4 and Type 5 — what we call Type 4+ — because you can weld the first composite layer to the thermoplastic liner. This structural connection helps to prevent the liner from collapsing, which is a problem.” Air Liquide emphasized this point in an end of project summary: “All cylinders are hydraulically pressure tested after manufacturing. To meet ISO 14687 hydrogen gas purity requirements for a fuel cell, cylinders have to be decontaminated to remove water, etc. The best way to do this is repeated cycles of compression and vacuum. In some cases, the plastic liner can collapse during these cycles.”

Materials

“We didn’t really have a choice in what materials to use,” says Callens. “When we started the project, it was difficult to find carbon fiber/thermoplastic tape in the market that fit both the LATW process and required properties for the tanks.” During material suitability trials lead by Faurecia, the first tested was Toray T700 carbon fiber-reinforced PA11 tape from Barrday (Cambridge, On., Canada). But with too much dry fiber in the tape surface, it was difficult to achieve a conforming in-situ consolidation during LATW. The project then sourced off-the-shelf CF/PA12 tape from Suprem (Yverdon-les-Bains, Switzerland), which produced six tanks with reasonably good burst test performance, but the ability to achieve a Type 4.5 tank where the composite laminate is welded to the liner had to be improved. Thus, the project worked with Suprem to procure a specialized CF/PA11 tape to match the PA11 liner and manufactured an additional four tanks.

“We worked a lot in the past with Suprem because their tape quality is very good for the LATW process,” adds Callens. “But that’s changing; we see many other manufacturers able to make sufficient quality tape today. Cetim is working with more manufacturers who want to qualify tape materials for hydrogen tanks. There has been a significant increase in interest.”

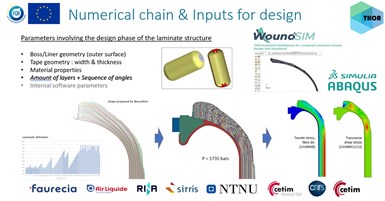

Winding simulation

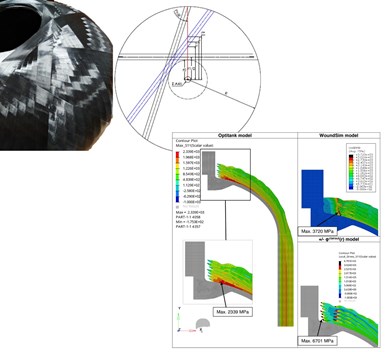

Project partner Sirris was in charge of the design and used WoundSIM software developed by Dassault Systèmes (Vélizy-Villacoublay, France) with Simulia development partners QustomApps (Ponder, Texas, U.S.) and S Vertical (Châtenay-Malabry, France). (WoundSIM was released in 2019 and is now maintained by S Vertical.) Developed for thermoset composite winding processes, WoundSim uses classical and well-known theories to describe fiber angle distribution, thicknesses and shape of the layers for a generally assumed thermoset filament winding process. During several design loops, Cetim assisted Sirris to analyze material behavior and LATW process specifics as well as some limitations of the models to evaluate different configurations. Adjustments were made and the tank was modified according to the project schedule. Development phases included:

- Definition of stackings with liner/boss geometries and different tape characteristics (iterations 1 and 2).

- Specific studies on interlaminar shear behavior after first iteration result (burst at 738 bar due to weak processed material performance and consolidation).

- Optimization of a boss design to specific requirements of THOR project.

- Definition of a new sequence of winding angles based on THOR inputs (iteration 3).

Despite a reduced time for developing this new design, tanks #4 and #5 produced by Cetim achieved 1,466 and 1,476 bar, respectively, in burst testing.

Source | “Manufacturing burst test and modeling of high pressure thermoplastic composite overwrap pressure vessel”

However, the LATW process using TPC materials is quite different from thermoset wet winding. Notably, in-situ consolidation of medium-width tape has a strong sensitivity to process parameters (temperature, compaction pressure) and tape characteristics (homogeneity in width, thickness and compressibility during consolidation). WoundSIM was not able to predict the right shape for TPC materials near the boss, which affected failure analysis.

During the correlation phase of the design work, Cetim used its in-house developed software, Optitank, to fill a gap in the detailed modeling specifically for TPC pressure vessels. Optitank uses a new theory to model composite tape stacking and geodesic path around the dome area, including adapted thicknesses and angles to correctly model the geometry and stiffness of the wound composite. (See Cetim paper: “Manufacturing, burst test and modeling of high pressure thermoplastic composite overwrap pressure vessel.”)

Demonstrator tanks and testing

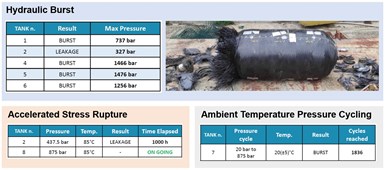

The THOR project built 15 TPC tanks and validated their performance through tests outlined in EC79 qualification, including:

- Burst test — fill tank with water, hydraulically pressurize until leak or burst occurs.

- Accelerated stress rupture (ASR) — fill tank with water, hydraulically pressurize at 85°C to 125% NWP without rupture for 1,000 hours or until leak occurs.

- Ambient temperature pressure cycling.

As can be seen in the table below, target burst pressure was 1,575 bar. Tanks 4 and 5 achieved the highest burst pressures, the latter within 6% of the target value. “At Cetim, we believe there is still a big improvement that we can achieve on the design of the tank and winding that would allow meeting this target,” says Callens.

THOR project tank testing. Source | Slide 76, presentation part 1, THOR project dissemination workshop, Sept. 21, 2022, at Cetim Technocampus.

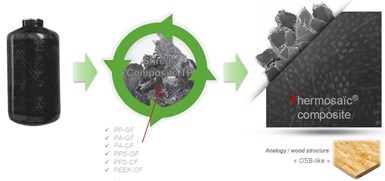

Recycling

Recycling was a key part of the THOR project. “The idea was to show that you can recycle the EOL tank, with added value,” says Callens. “This is compared to just crushing all of the tanks and making a recycled compound for injection molding. That approach is quite low in terms of value because you start from a high level of composites performance and you finish with recycled short fiber-reinforced polymers. Instead, we showed a technology where you can make chips from the the EOL tanks that keep the length of the carbon fibers. We then put these chips into the award-winning Thermosaïc process we have developed at Cetim. This process transforms the chips into ready-to-use recycled panels that have an intermediate mechanical performance between short fiber compounds and classic continuous fiber composites. These panels can then be used for the manufacturing of new stamped parts.”

Due to time constraints, this recycling work had to be done in parallel with tank testing. Thus, actual tanks were not used but representative carbon fiber/PA11 materials were used to validate the recycling approach. After various trials, a process was identified that allowed chips from EOL tanks with fiber lengths of 60-200 millimeters and a thickness of 0.3-0.4 millimeters.

Best results on Thermosaïc panels were achieved when PA11 powder was added for 37% fiber volume. There was no thermal degradation, and the bending performance was similar to compression molding and SMC materials, but Cetim notes further improvements are possible. These panels were then tested in stamping trials and showed good processability into complex shapes and also in trimming/machining.

HySpide TP new machine for H2 tanks

Since the end of THOR, Cetim has continued its R&D program on H2 tanks (e.g., HyMEET) developing specific design and simulation tools and investing in a new, higher speed winding and tape placement system that enables 10 times higher winding speeds. Installed in September 2023, the new HySpide TP machine was developed for H2 tank manufacturing and features a new, optimized tape winding head from AFPT with a 150-kilogram payload KUKA KR 150-2700 robot and a rail/track with 4.1 meters of linear movement. Cetim reports that the tape laying speed will be increased up to 100 meters/minute in the cylinder part of tanks and 15 meters/minute in the domes, with also a new machine axis allowing design optimization in this area. The machine can also lay 40-millimeter-wide tapes, compared with 25 millimeters previously. The cell also has an external tape supply unit that can accommodate winding reels holding 8,000 meters of tape, the maximum production capacity offered by suppliers.

“Today, the cost of materials used in wet winding is quite low because it’s been used for many years,” says Callens. “While thermoplastic composites tapes are more expensive now, we believe they will be lower in 2-3 years with the materials manufacturer developments that we are seeing, but there is still a need for higher process speed machines.”

Proven feasibility, future industrialization

A 63-liter thermoplastic composite pressure vessel made with Cetim’s new HySpide TP system. Source | Cetim

“We showed from a technical point of view that you can make TPC tanks that are able to reach the required specification,” says Callens. “That was the first challenge of THOR — that this is feasible compared to thermoset solutions. However, we still have to show that this TPC manufacturing process can be an industrial solution in the future — which means showing we can optimize a specific TPC design and make tanks with a short cycle time to reach a cost target that fits the industry.” The first such tanks with optimized design, manufactured using HySpideTP will be displayed by Cetim at JEC World 2024 (March 5-7, Paris, France).

The THOR project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking (JU) under grant agreement No 826262. The JU receives support from the European Union’s Horizon 2020 research and innovation program and France, Belgium, Italy, Norway.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRead Next

AFPT participates in LeiWaCo project for economic production of thermoplastic composite hydrogen tanks

Laser winding/welding will help 3-year project develop cross-industry container-based transport/supply unit for cryogenic liquid hydrogen, aiming for TRL 5 via demonstrator manufacture and testing.

Read MoreTHOR project develops mass-producible CFRTP hydrogen tanks

The three-year project, concluded in 2022 and aided by partners spanning the entire hydrogen storage supply chain, tested and produced 15 thermoplastic tanks, with the goal of achieving broader market introduction.

Read MoreIndustrial production line for recycling thermoplastic polymers and composites into organosheet

ThermoPRIME and Thermosaïc technologies recycle plastic and composite waste via modular, flexible equipment.

Read More