Ulster University, Synthesites advance intelligent cure monitoring

Research collaboration to enable active control and optimization for RTM process for composite structures manufacture.

Researchers led by Dr. Calvin Ralph from Ulster University’s (Belfast, U.K.) Advanced Future Materials and Manufacturing (AFMM) cluster are collaborating with Synthesites (Uccle, Belgium) to advance real-time monitoring of the resin transfer molding (RTM) process in a representative closed mold system. The open-ended collaboration began in June 2022.

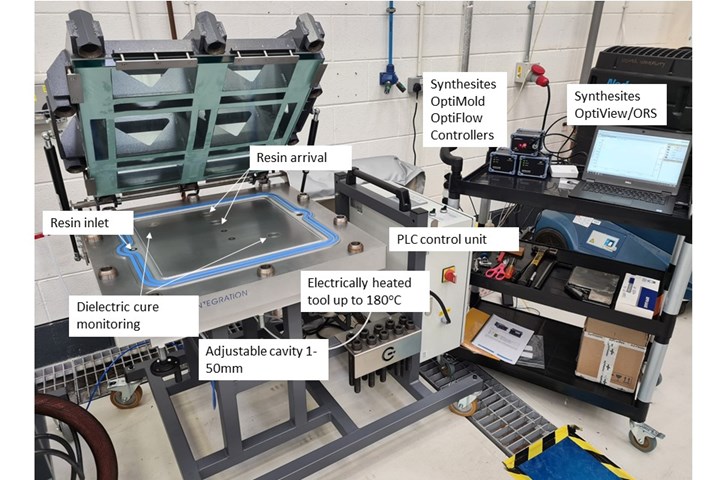

Through this monitoring, the team is developing digital twin capabilities that will use live data signals to actively control and optimize the infusion/curing process with the added benefit of increased traceability of the composite part during manufacture. The Synthesites dielectric monitoring systems are based on the direct measurement of resistivity (DC) and accurate temperature of the resin. Using Optimold and Optiflow systems, researchers are able to track resin status such as resin arrival, temperature, viscosity, gelation, degree of cure and Tg can be recorded during product development and/or production using a range of durable and consumable sensors. Quality control issues such as mixing ratio, resin aging and other features can be also monitored and controlled using this technology (learn more about the system, “DC dielectric sensors for industrial composites production”).

Synthesites has also worked in close collaboration with other composites manufacturers in wind energy, aerospace, automotive and other industrial sectors to improve resin monitoring intelligence, including Purdue’s CMSC, the National Composites Centre (NCC) and the Netherlands Aerospace Centre (NLR).

The AFMM cluster is a group of academics and researchers at Ulster University encompassing areas of advanced composites and polymers, nanomaterial development, process development control simulation, material modeling, sensors and data analytics, sustainable and digital manufacturing. Composites, in particular dry fiber preforming, composites manufacture and characterization, is a key spoke to the group’s hub as it has industrial focus and seeks commercial application for the group’s research in sectors including aerospace, automotive, renewable energy and marine.

Ulster University is a core partner in the Northern Ireland Advanced Composites and Engineering (NIACE) center that has been placed to bridge the gap between academia and industry within Northern Ireland and the wider national/global composite strategy.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.