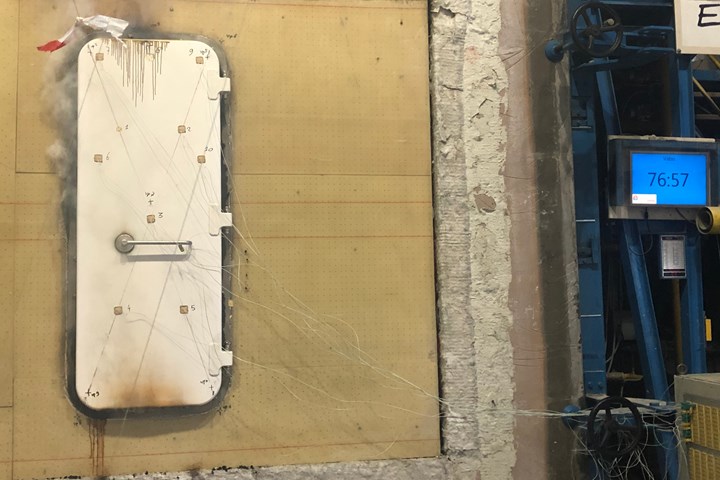

VABO Composites' maritime fire doors pass 60-minute resistance test

FRD60 composite doors cover all B15 and B30 requirements and enhance VABO portfolio for the company’s commercial, superyacht and naval sector client base.

Photo Credit: VABO Composites

VABO Composites (Emmeloord, Netherlands) has launched a new maritime fire door that meets all the criteria for the 60-minute resistance test. According to the company, these FRD60 doors enhance its portfolio for the company’s commercial, superyacht and naval sector client base around the world.

VABO manufactures composite doors and hatches for shipyards that wish to leverage the lightweight properties of composites in comparison to steel and aluminum. The company claims its composite products require virtually no maintenance, and VABO FRD30 doors cover all B15 and B30 requirements in terms of fire resistance.

“VABO has made significant investments in developing a door that reaches the 60-minute target,” explains sales and marketing manager Jeroen van Deutekom. “Although it took considerable time and effort with a stringent testing regime, the VABO team has now amply passed the 60-minute milestone. Our tests follow the FTP code [FRD60] to cover the equivalent A60 and A0, with VABO’s high quality level guaranteed.”

According to VABO, this expansion means it can now support an even wider part of the markets in which it operates, with a complete selection of hinged doors and hatches that includes those which need to be fire resistant.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

.jpg;maxWidth=300;quality=90)