Williams Advanced Engineering develops lightweight structures to protect troops

The company is using its Formula One-derived composites technology to build strong, lightweight 3D composites structures for U.K. defense applications.

Williams Advanced Engineering (Grove, U.K.) is working with the U.K.’s Defence Science and Technology Laboratory (Dstl) and Defence and Security Accelerator (DASA) to develop composite 3D structures for battlefield shelter protection for troops, using Williams’ Formula One-derived technology and processes.

Williams Advanced Engineering, the engineering and services business from the Williams Group that also includes the ROKiT Williams Racing Formula One Team, has developed patent-pending composites technologies and processes enabling the creation of strong and protective, but lightweight, structures. The company will be implementing its proprietary technology in the DASA “Take Cover” competition, which calls for innovative approaches to battlefield protective structures. Williams believes that its proposal will enable the U.K. Ministry of Defence (MOD) to become a leader in implementing advanced composite materials across all of its operational activities.

Williams’ composites technology is said to enable innovative approaches to the use of fiber-reinforced polymer and unlocks the use of composites for modular structures, allowing for the integration of varying levels of protection, depending on the requirement.

On the battlefield, minimizing the weight of equipment is essential, reducing the logistic burden as well as the burden on the individual. The material properties of composites are said to offer significant mass advantage over traditional materials such as steels and other alloys, but issues surrounding production tooling, ease of handling and cost have constrained composites to low-volume high-performance applications. This was the driving factor behind Williams Advanced Engineering innovating a new composites technology to revolutionize applications where rapid manufacture, ease of assembly and low cost are essential.

Current temporary structures used on the battlefield traditionally use materials such as corrugated iron, sandbags and mechanical fasteners, the weight and volume of which can lead to difficulties surrounding transportation and on-the-ground deployment. Williams Advanced Engineering also says that the mechanical properties, such as the specific strength, of corrugated iron are often significantly lower than that an equivalent piece made of glass fiber-reinforced polymer.

The company says its ability to implement a variety of fiber types depending on the application will enable them to build equipment to protect against threats such as blasts, fragmentation, ground shock, or thermal detection.

“DASA was created to find and fund exploitable innovation for defense and security,” says Dr. Adam Staines, DASA delivery lead. “Key for this mission is wider engagement with non-traditional suppliers across a range of industrial sectors. Accessing cutting-edge technology developed initially for Formula One is a prime example of this engagement. Lightweight foldable materials which can be assembled quickly to provide protection for troops was a key aim of this DASA themed competition. In addition to protecting troops and saving lives on the battlefield this technology has potential uses for domestic security and humanitarian applications.”

“To think that innovations from the team here at Williams Advanced Engineering can deliver enhanced, lighter protection for the Armed Forces is a great feeling for us,” says Craig Wilson, managing director of Williams Advanced Engineering. “We look forward to working with Dstl and DASA to enable deployment of our technology by service personnel for their protection.”

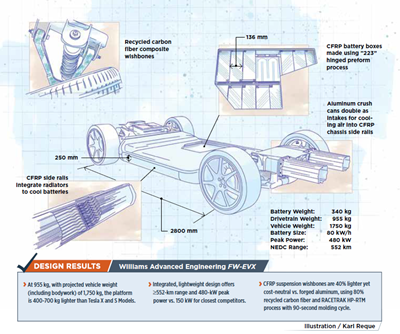

Read CW’s coverage about the company’s multifunctional chassis design for electric vehicles.

Related Content

Airbus presents unmanned Wingman concept

Fighter jet model unveiled at ILA Berlin, made from an iron structure and composite outer skin, will deliver more tactical options, supporting future combat missions.

Read MoreHypersonix receives CMC scramjet manufacturing demonstrator

HTCMC component demonstrates manufacturing of future Spartan scramjet engine required for reusable hypersonic vehicles capable of up to Mach 12 flight.

Read MorePull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

Read MoreMilliken & Co. partners with MMI Textiles to offer Tegris thermoplastic

The commercial market partnership enables easier access to the Tegris thermoplastic composite fabric for defense customers in the quantities that they require.

Read MoreRead Next

Williams Advanced Engineering introduces processes for cost-effective carbon fiber composites

The company’s two latest technologies, 223 and Racetrak, are said to be a step-change in the affordability of composite materials.

Read MoreEnergy storage in multifunctional carbon fiber composites

A need for lightweight energy storage technology is fueling the development of carbon fiber composite materials for car batteries and other electronics.

Read MorePushing EVs forward

Multifunctional chassis design and novel composites processes enable lighter, longer-range, safer electric vehicles.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)