AFS introduces sustainable FRP construction solutions

LAST Stair, Railing, Plank and Structural Member product lines offer a variety of fire-retardant composite stair and decking applications.

A Fiberglass Solution Corp. (AFS, Murrells Inlet, S.C., U.S.) is a structural and architectural fiberglass fabricator highlighting its fiber-reinforced plastic (FRP) LAST product lines, including LAST Stairs, Railing, Plank and Structural Member.

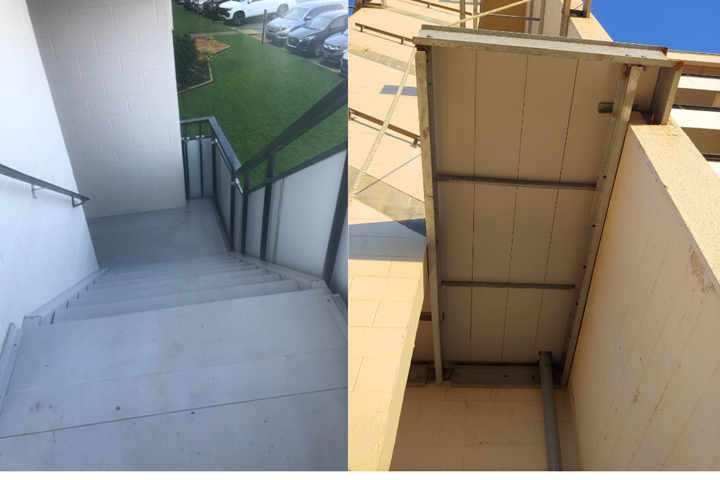

The LAST Stairs and Railing is AFS’ primary product line based off of industrial stairs which are known for their longevity, and low maintenance and replacement expenses. Specifically, the Stairs product uses fire-retardant FRP materials for stair treads, risers, stringers and landings. It is now available with architectural accents to fit aesthetic requirements for hotels, condos, resorts and residential properties.

The company also introduces FRP LAST Plank for use in replacing spalling or cracked concrete landings and walkways. The 12" FRP decking is said to offer a cost effective way to replace elevated concrete. It can be installed quickly and efficiently, eliminating metal pan replacement, the high cost of pumping concrete and the finishing of the concrete. LAST Plank is offered in a variety of stock and custom colors with anti-skid applied to the walking surface. The appearance of the new deck from the traffic side is clean and precise, and the underside of the decking is finish painted, AFS says.

LAST Plank offers more than 30,000 psi module of elasticity for a firm feel underfoot, the company says. According to Bryan Pratt, COO of AFS Corp., AFS has used the plank for a variety of projects to replace spalling landings in stair systems and spalling concrete mezzanines.

AFS Corp. also offers its FRP Structural Member solution, L2x12, a proprietary glass fiber-reinforced pultruded part that incorporates a fire-retardant resin. L2x12 is current used for stairs, landings, decking, structural frames and more, but has potential as a decking member when the 12" section is horizontal. L2x12, which was tested in the lab at lengths of 48" and 72", recorded an average flexural strength (30,000 psi) and flexural modulus.

Related Content

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

-

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.