Arris unveils structural flax fiber composite

High-performance natural fiber adds to the company’s other biocomposite offerings, helps achieve sustainability initiatives.

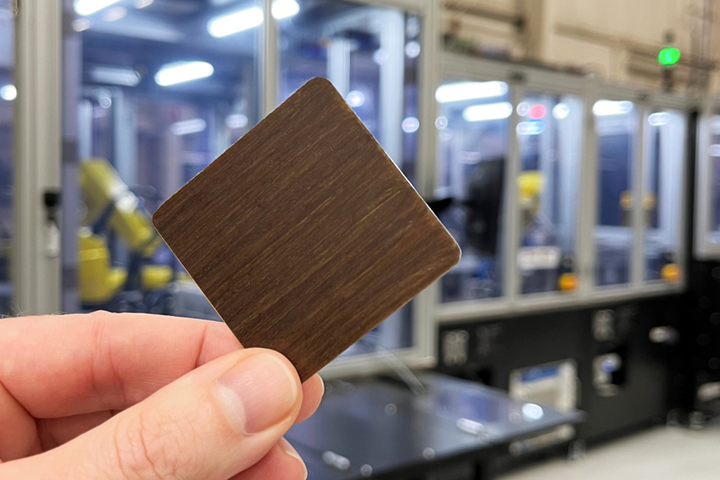

Photo Credit: Arris

Arris (Berkeley, Calif., U.S.) announces a new sustainable flax fiber composite material offering for structural applications, with high-performance capabilities to complement its already available bio-nylon resin material being used with carbon and glass fibers. Flax has <5% of the CO2e footprint compared to carbon fiber, aiding in emissions reduction.

Sustainability and innovative material development are at the core of everything Arris does as the team scales Additive Molding for a production capacity in the millions to meet demand. Additionally, Arris says it has doubled its in-house material production capacity as of February 2023 to support growing customer programs.

“Since we started, our R&D team has been researching and investigating recycled, recovered, and natural fibers, as well as recycled, bio-based and bio-synthesized polymers that help brands achieve necessary sustainability initiatives without sacrificing the best-in-class performance their customers have come to expect,” Bert Mannhalter, Arris vice president of research and development (R&D), says. “I’m excited to reach this breakthrough in processing flax fibers. Though it’s been used for cosmetic parts such as veneers and paneling, we now see a way to use these fibers for true structural applications.”

Related Content

-

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

-

Robotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

-

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

.jpg;maxWidth=300;quality=90)