Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

(Top left) Digital technologies are key for the aerospace industry to achieve its decarbonization ambition. (Center) Airbus is exploring natural fibers and bio-resins as part of its Future Materials initiatives. (Bottom left) The lightweight composite A350 lower wing cover is manufactured at the Illescas plant and sent to Broughton, U.K., but new materials and technologies are needed to meet Airbus’ decarbonization ambition. Source | Airbus

This blog is an online sidebar for CW’s September 2024 article, “Plant tour: Airbus, Illescas, Spain” and is based on discussions during and after that tour. It looks at where Airbus is headed with respect to composites and circularity including recycling, bio-sourced materials, digitalization and more.

Sustainability and new aircraft development

The A350 was a new step in composite airframe component production (top) but new technologies are needed to meet aviation’s decarbonization goals (bottom). Source | ECO-COMPASS project (Airbus was a partner) and Airbus: Decarbonisation

“‘We pioneer sustainable aerospace for a united world,’” is Airbus’ mission statement, explains Mónica Álvarez, head of the Airbus Illescas production plant. “We want to lead an ecosystem of change to decarbonize aviation.”

“The A350 was a new step in composite component production,” she continues, “driven by weight savings and less fuel consumption. We have also contributed to the journey with our latest generation of A320 family aircraft. But for future gains, we need new materials and higher productivity industrial systems to enable us to ramp up quickly and contribute to our decarbonization ambition.”

“There are two priorities for Airbus right now,” notes Álvarez. “The new replacement for single-aisle narrowbody aircraft and the ZEROe short-range hydrogen-fueled electric aircraft, scheduled to fly by 2035.” In its 2023 Annual Report, Airbus indeed noted that it will be making crucial decisions about the architecture of its next-generation single-aisle aircraft and first hydrogen-powered airliner. “We expect to have a high amount of composites on both,” says Álvarez. Thus, the capability to ramp up new composite structures is key. For example, production of the current A320/A321 family of narrowbodies will be increased to 75 aircraft per month by 2027.

Future of composites depends on circularity

“Making our aircraft lighter is key,” says Blanka Szost-Ouk, materials Fast Track leader at Airbus. “I’m one of six Fast Track leaders at Airbus that is developing the roadmap for key technologies, and materials is one of those.” The others are electrification, autonomy, connectivity, industrial and AI. “Composites are one of the lightest materials that we can use, but their end-to-end circularity needs to be improved.”

As an Airbus expert in multifunctional composites, Tamara Blanco agrees. Her scope of work now includes sustainability as a key function for composite materials. “We are following the needs of the business,” says Blanco. “Composites are the materials of choice for future aircraft due to their lightweight capabilities versus aluminum, and that is key to meet the requirements for reduced fuel consumption and CO2 emissions. However, to ensure composites are the materials chosen for the future, we need to develop solutions for these other areas in the life cycle [i.e., other than in-service use] where composites have a larger environmental footprint — such as the material production, waste management and also end of life [EOL]. I’m focusing a lot on developing the best solutions for composite materials in these areas.”

“We are working for resins and fibers that are made from reduced emissions sources,” says Szost-Ouk. “But we also have very interesting projects in Illescas where we give composites — in this particular case, carbon fiber-reinforced thermoset prepreg — a second life. We reuse the uncured material that would normally go to waste and make another part from these materials, such as fillers for the stringers on the A350 lower wing covers.”

Airbus is recycling prepreg tape into fillers/noodles for A350 wing cover T-stringers, similar to the one shown here, but using extrusion instead of 3D woven textiles. Source | CW news, 3D Noodles International AB

“A circular economy is especially relevant for us as we look at materials, even more so for composites,” says Blanco. During CW’s tour of Airbus Illescas, she pointed out a forming cell where leftover ends of prepreg tape rolls are put into an extrusion machine, converting them into triangular fillers/noodles for the A350 wing cover T-stringers.

“We must enable recyclability of our production scrap but also of EOL parts,” she continues. “Here, we have a collaboration between the Illescas plant and a large civil engineering company Comsa, in order to mechanically recycle cured composite scrap to be used as reinforcement for concrete material.”

Airbus oversaw the HELACS project to demonstrate the dismantling and recycling of carbon fiber composite aircraft components. Source | HELACS project news and CW news

Another initiative in this area is the Clean Sky 2 project HELACS (Holistic processes for the cost-effective and sustainable management of End of Life of Aircraft Composite Structures), which ran from January 2021 to December 2023. Airbus acted as the topic manager with a consortium led by the Aitiip Technology Center (Zaragoza, Spain) and including Teruel Airport (Teruel, Spain), the research center Centexbel (Ghent, Belgium) and carbon fiber recycling company Gen 2 Carbon in Coseley, U.K. The project demonstrated industrially and environmentally safe methods for dismantling and recycling carbon fiber composite aircraft components. Dismantling techniques included waterjet cutting and an autonomous robotic system, while recycling of components was mainly based on pyrolysis to recover the carbon fiber and produce new materials.

Multifunctionality, electrical and thermal conductivity

Multifunctionality in composites continues to be a key trend for Airbus, says Blanco. “Going from a metal fuselage to a composite fuselage in the A350, we had to implement different solutions to deal with lightning strike protection [LSP],” she explains. Thus, certain composite components not only provided lightweight structure, but were also engineered with electrical conductivity as part of the LSP system. “And now we are working on enhanced lightweight solutions for the next generation of aircraft based on new materials, designs and different technologies.”

Airbus is pursuing advancements in electric flight such as (top left clockwise) ZEROe fuel cell and hydrogen-powered aircraft, the ASCEND superconductive powertrain demonstrator and the Cryoprop electric powertrain demonstrator. Source | Airbus

"Multifunctionality is even more important for next-generation aircraft because they will be more electrical,” Blanco continues. “This is in line with aviation ambition to reach net zero CO2 emissions by 2050 set by IATA, ATAG and ICAO.” She explains that Airbus has defined an energy roadmap, which takes advantage of synergies between numerous Airbus activities and products. “It includes three main trends that are being investigated in parallel: Incremental developments and adoption of SAF [sustainable aviation fuel], modular hybrid electrics and the ZEROe aircraft, which are mainly based on the use of liquid hydrogen for propulsion. From our group we are committed to support this roadmap to enable, as much as possible, the combination of needed functionalities with the lightweight properties composites can offer.”

“We are giving priority to two functionalities for composite materials: electrical and thermal conductivity,” says Blanco, “which are even more critical for next-generation aircraft." She explains that these functions are key for LSP and other electrical functions to prevent electromagnetic hazards. “Additionally, we are trying to find more opportunities to use multifunctional composites, for example, in anti-icing of future aircraft."

Another priority is to increase the thermal conductivity of composites, says Blanco. “This is more and more important for us in future products, where we are investigating other fuel systems such as hydrogen, which requires thermal management.” She is referring not only to the potential use of cryogenic liquid hydrogen, but also to the large heat output of fuel cells. “That’s why these types of functionalities in lightweight composites are key and we’re investigating them for future products.”

“I would also say that if you think about the aircraft, everybody wants to be more connected,” notes Szost-Ouk. “Thus, for future aircraft, we will need a lot of electricity and cables for data-driven systems, which produce heat as they push more and more power through. So, the issue of thermal conductivity also includes general heat management across the aircraft.”

“Although multifunctionality can be enablers for future electric

and low-carbon emissions aircraft, it is very relevant to link new material solutions with weight saving from the very beginning,” says Szost-Ouk. “They always needs to be lighter than those currently used. Some designs we have looked at were sustainable, but they were not lighter, and we couldn’t use these because it would have increased the cost per flight for our customers operating the aircraft. So, we must always have this balance.”

“And not only with lightweight but also with circularity,” adds Blanco. “New materials, including multifunctional composites, need to be in line with our key targets in terms of end-to-end life cycle — from raw material production to EOL strategies.”

Composite sustainability and digitalization

“Finding balanced circular material solutions is increasingly linked with digitalization,” says Szost-Ouk. “For example, the composites industry is pursuing increased materials digitalization, which involves collecting and working with data in digital formats for more efficient storage, access, continuity and analysis. And this enables using information in a proactive, predictable way, to to improve our products across their entire lifetime, from the innovation phase through to EOL.”

Circular material solutions are increasingly linked with digitalization. Source | Airbus: Industry 4.0 and Future Materials

She explains that Materials Sustainability is one of several transversal roadmaps that intersect across Airbus’ businesses and are linked to digitalization. “I see a strong link between sustainability/circularity and digitalization,” says Szost-Ouk. “In fact, I cannot imagine circularity without digitalization. For example, data continuity is key for us to track the history of materials in our parts. And we also are working on digital solutions that will enable us to be faster in our innovation.”

This approach has been announced by carbon fiber producer Toray (Tokyo, Japan) in its Nagoya research hub and in a new flame-retardant prepreg for aircraft applications. Toray is using materials informatics to reduce lead times for such new materials and said it will apply this approach to thermal conductivity and electrical conductivity in new prepregs for aircraft and other industries. Polymer supplier SABIC (Riyadh, Saudi Arabia) is also using this approach, developing new products in months versus years by using Schrödinger’s physics-based computational platform. (See “Fast-tracking next-gen polymers”).

Airbus is pursuing similar initiatives, says Blanco. “For the future, in each of these development areas, digitalization is a key enabler. We are pushing digitalization through our company, not just for circularity, but for finding answers much more quickly than in the past.”

Advancing sustainable composites TRL

How does Airbus evaluate these new composites solutions? “In Airframe R&T, we follow the typical TRL [technology readiness level] process used by the aviation industry, where we demonstrate the maturity of a technology step by step,” says Blanco. “We usually start at TRL 2 or 3, but when we do have lower TRL solutions, then we rely on the scientific and external community to demonstrate the viability and application for us. We define clear criteria or performance indicators, and we measure the evolution of the technology versus these.”

TRL levels. Source | European Space Agency

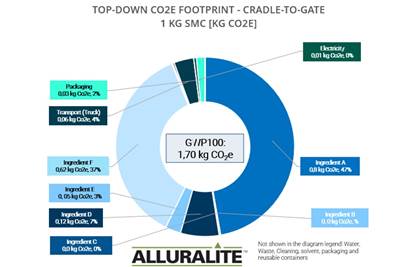

“Now,” she continues, “we also have strong criteria for circularity from the very beginning. We take these into account even before TRL 3. We do a life cycle assessment [LCA] or environmental evaluation to be sure that we will be developing something that is compliant with our sustainability commitments and targets.”

These include not only sustainability in the wide sense of the word, says Szost-Ouk, but also health and safety. “In resins, we are monitoring and already anticipating some potential future substance compliance requirements with EU regulations. We do not start at all with a material that has any concerns in these areas. That must be cleared from the beginning.”

Source | “Towards a circular economy in the aviation sector …, ” published by the ECO-COMPASS project.

After that, says Blanco, developments are measured against established criteria, including for circularity and functionality. “Composites need to be more competitive in terms of cost as well,” she emphasizes. “And we are working hard on this to ensure composites are chosen for future aircraft because they are needed in terms of lightweight.”

Szost-Ouk says recyclability is also increasingly important. “We not only evaluate the LCA of the technologies we will develop, but we also have specific projects to develop more circular composite solutions, including recycling and EOL solutions as well as bio-sourced composites. We’re putting a lot of effort into this, and I have specific projects in this area.”

Qualifying biocomposites

The historical problem with bio-based composites is that they haven’t offered the same high performance currently required for aircraft. Will this just be a matter of long-term development? “We will definitely not compromise lightweight because the drawbacks for the environment will be higher,” says Szost-Ouk. “Obviously, we have specifications, and any materials we develop must meet these requirements. I believe there is a way forward to find bio-sourced replacements — which could result in a lower environmental footprint than current oil-based materials — for some of the composite materials we are using today, but we still have to go through the same qualification path. Here, computational tools using AI and/or quantum computing will be a stepping stone.”

Airbus is testing bio-based composites on the Pioneer Lab helicopter. Source | Airbus: “Pioneering for the programmes” and “Developing bio-based composites that are fit to fly”

Blanco gives an example. “We will be testing a bio-based carbon fiber in a helicopter as a drop-in solution to replace current carbon fiber composites. This material is coming from wood waste, and our goal is to have the same performance but with much lower CO2 emissions in carbon fiber production because it’s coming from a bio-source instead of the current petrochemical-based PAN precursor. This fiber has now flown in our helicopter flying lab. So, we are on the way to demonstrate that we can obtain both resins and fibers from bio-sources, looking first at fibers, and proving the same performance as current materials.”

“If we think about bio-based materials, such as PA11 that comes from the castor plant, the properties are a bit weaker compared to the petrochemical-based polymer,” says Szost-Ouk. “So, we will have to develop alternatives. But I think these types of solutions can be aided with digital technologies, which will speed up our ability to find solutions in the next few years. We at Airbus are very active in this area, and not just doing experimental work but also supporting computations with the latest in innovative technologies.”

Moving forward as a supply chain

As the efforts to reach these sustainability targets ramp up, Szost-Ouk also notes that Airbus is an end user, “so we very much depend on the material suppliers. We need to work more closely with them, and they will have to be more open with us about all of these polymer and material formulations because they are the ones that actually will have to alter their current chemistries.” She adds that Airbus is indeed pushing for this collaboration throughout the supply chain. “Even in procurement, we are working to support and guide our composite suppliers, giving more weight in prioritization if they can show us how traceable the material is and how circular it can be. In order to find the solutions the aviation industry needs, we need to do it together.”

“We must lower the carbon footprint during production not just of parts, but also of the resins and carbon fiber,” says Blanco. “This is a big challenge but necessary to lower these effects in LCA, enable the increased use of composites in future aircraft and meet Airbus’ decarbonization ambition.”

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Life cycle assessment in the composites industry

As companies strive to meet zero-emissions goals, evaluating a product’s carbon footprint is vital. Life cycle assessment (LCA) is one tool composites industry OEMs and Tier suppliers are using to move toward sustainability targets.

Read MoreMultifunctional composite structures across end markets

Innovators find new ways to add functions — from anti-icing to 5G signal transmission to structural batteries and beyond — into structural composites.

Read MoreThe next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read More