Balmoral launches composite scour protection system

Integrated scour prevention solution for fixed offshore wind turbine systems non-invasively protects against turbine foundation instability and cable damage.

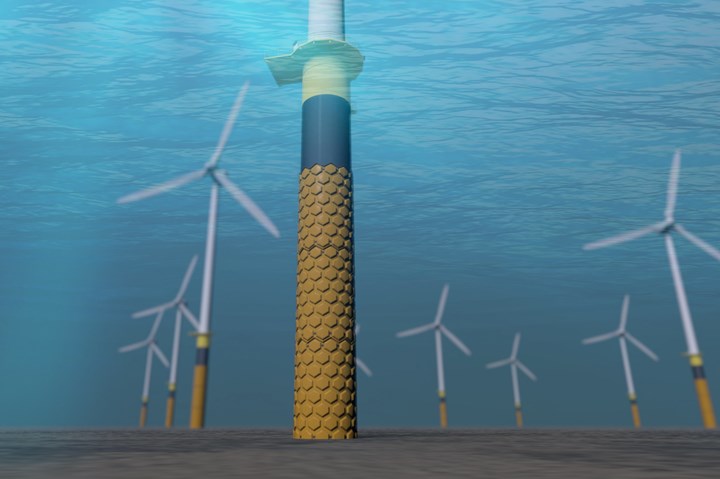

Balmoral (Aberdeen, U.K.), an established supplier to the oil and gas sector, has adapted and transitioned several of its buoyancy and protection solutions — cable protection, bend limiting devices and crossover solutions and others — for use in the fixed and floating offshore wind sector (read “Composites protect subsea cables for offshore wind power”). Now, following extensive research and investment, the company is introducing Balmoral HexDefence, a lightweight composite construction that aims to drastically reduce scour phenomena around fixed wind turbines

Scour refers to the erosion of seabed sediment caused by currents and waves. These conditions can lead to turbine foundation instability and interarray cable damage, ultimately resulting in expensive cable failure. To mitigate these consequences scour protection is used to defend the seabed around a monopile structure.

Scour protection typically involves the installation of a layer of material around the base of the monopile to prevent sediment erosion. This can be made of various materials including rock, concrete or a specially designed geotextile fabric. The layer is placed on the seabed around the monopile to dissipate the energy of the fluid flow and reduce erosion rates.

These measures need to be carefully monitored to avoid damage to the turbine, seabed and any associated cabling. Balmoral HexDefence, an integrated scour protection and flow reduction system, minimizes offshore operational costs and potential cable failure. The HexDefence structure eliminates the requirement to dump rock, instead providing a non-invasive approach to protecting the monopile and the immediate surrounding area.

Its lightweight composite construction and streamlined installation method is said to makes it easy to install without the need for additional vessels, resulting in an improved carbon footprint for all operations. Additionally, the system can be used with antifouling coatings and does not require special equipment for end-of-life recovery.

“We believe Balmoral HexDefence represents a significant step forward for scour protection, offering highly cost-effective performance enhancement across installation, management and maintenance,” Fraser Milne, the company’s engineering and projects director, says. “The interlocking panels are generally 10m long and custom-sized to fit varying monopile diameters and feature integrated lifting and access points. In simple terms, the installation process involves sinking the foundation, sleeving it with HexDefence, fitting the transition piece and assembling the pylon and blades. The system is also suitable for retrofitting to existing monopile structures.”

Preliminary work on Balmoral HexDefence was based on existing VIV suppression products used widely by the oil and gas sector. Research considered a scaled variant to investigate scour evaluation on downstream flow and the effect of accelerated currents around the monopile. Final prototype testing was completed at a national hydrodynamic laboratory.

“We believe the system can save wind farm developers around 70% in installation costs when compared to traditional rock dumping methods,” Milne says. “With the exponential growth of offshore wind worldwide we believe Balmoral HexDefence can be a key financial enabler and a critical infrastructural element of future offshore fixed wind farms.”

Related Content

-

Honda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

.jpg;maxWidth=300;quality=90)