CAMX 2019 exhibit preview: AGC Chemicals

AGC Chemicals is featuring its modified polyetheretherketone (PEEK) and Fluon+ EA-2000 resin at CAMX 2019.

Source | AGC Chemicals

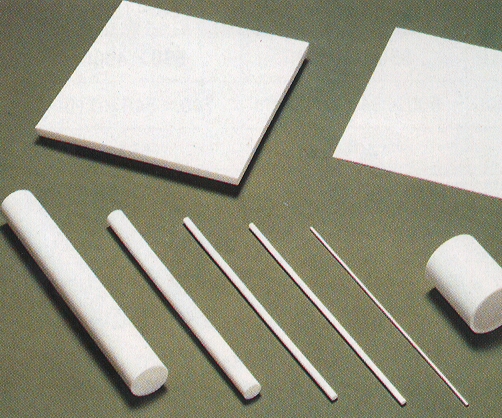

AGC Chemicals (Exton, Pa., U.S.) is featuring its modified polyetheretherketone (PEEK) and Fluon+ EA-2000 resin.

The company’s modified PEEK — mPEEK — is enhanced with specialty fluoropolymers said to improve impact and wear resistance, flexibility and electrical properties. The polymer can be used to produce different geometries such as sheets, rods, tubes, gears, liners, wire and cable insulations, and films that withstand demanding operational conditions. Compared with standard PEEK, mPEEK is said to improve processability via extrusion molding, injection molding and compression molding, and demonstrates a lower dielectric constant than standard PEEK at temperatures up to 260°C. The company says that this specialized fluoropolymer technology has also potential for property enhancement with other polymers.

Fluon+ EA-2000 resin is a functionalized, high-temperature adhesive polymer said to be ideal for use in continuous fiber-reinforced thermoplastic (CFRTP) applications that require high temperatures. This resin offers one-step processing with other polymers or metals, and reportedly eliminates the need for surface treatment or a separate tie-layer, and is heat-resistant to 260 °C. It is also said to exhibit better chemical resistance compared to other conventional materials, and in powder form can be used as an additive for engineering thermoplastic polymer matrices such as polyamide. Fluon+ EA-2000 can also be used as the primary matrix resin for high-temperature CFRTP applications when polyamide and epoxy are unsuitable.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

.jpg;width=70;height=70;mode=crop)