CAMX 2019 exhibit preview: Boston Materials

Boston Materials is introducing its Supercomp z-axis milled carbon fiber reinforcement products at CAMX 2019.

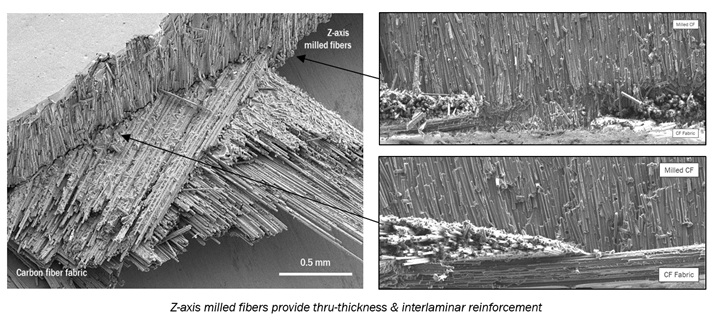

Fig. 1. Source, all images | Boston Materials

Boston Materials (BM; Bedford, Mass., U.S.) is announcing the launch of its Supercomp z-axis milled carbon fiber reinforcement products.

Supercomp 1015, 1015 Sport and Supercomp 2515 prepregs target customers that require durable, high-performance and differentiated products (Fig. 1). Reinforced with Z-axis milled fibers, Supercomp prepregs reportedly improve through-thickness properties by 300%, and double the ductility without diminishing in-plane strength or modulus when compared to conventional prepregs. Supercomp prepregs are commercially available, and Supercomp dry fabric reinforcements are being trialed with select customers.

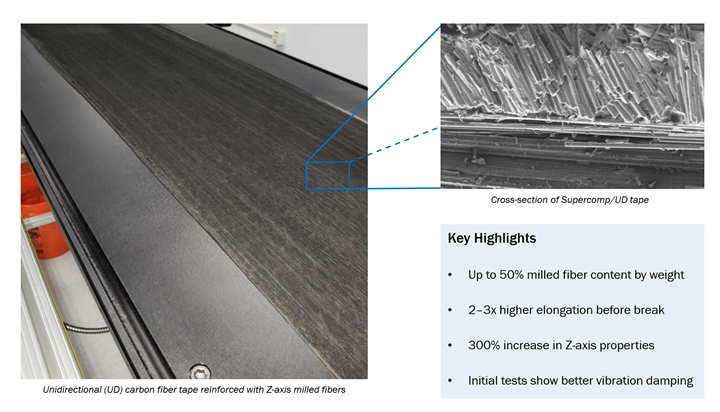

Fig. 2

Supercomp products feature z-axis milled fibers (Fig. 2) that mechanically bond layers of a laminate composite together and provide a uniform and non-crimp z-axis reinforcement. At the core of this technology is the ability to orient milled carbon fibers in the z-axis. Supercomp prepregs are currently formed by depositing and aligning z-axis milled fibers in commercially available carbon fiber fabrics or unidirectional tapes (Fig. 3) and then applying resin films.

Fig. 3

Z-axis milled carbon fiber content ranges from 75 to 170 microns, fiber areal weight from 280 to 375 gsm and total prepreg areal weight from 490 to 667 gsm depending on the grade of Supercomp. Boston Materials also says it can vary the amount of milled carbon fiber content and the orientation either z-axis or off-axis on fabrics depending on the desired properties.

Applications currently include sporting goods, prosthetics and industrial components. High-demand applications, including aircraft interiors, containment cases, and high-temp components in the aerospace sector are being explored. Boston Materials is also developing thermoplastic products that are ideal for high-volume production (for example, automotive or consumer electronics).

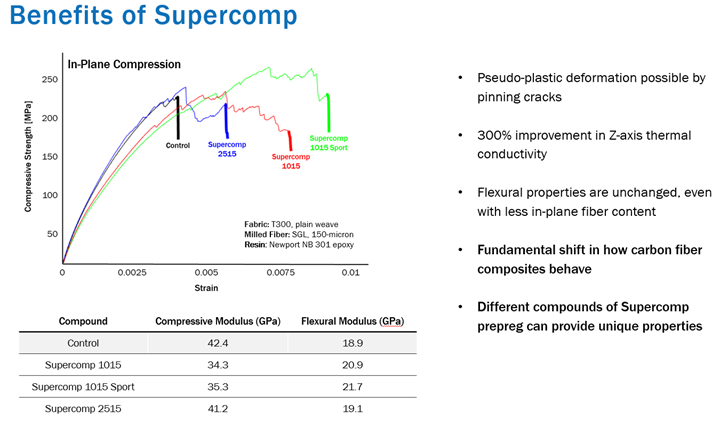

According to the company, Supercomp was created to overcome delamination issues of traditional 2D composites, replacing them with a patented fiber reinforcement that delivers highly differentiated functionality and performance (Fig. 4). Supercomp technology is designed to be price-competitive with current materials but with increased mechanical, thermal and electrical properties and performance.

Fig. 4

Supercomp products are specifically designed to integrate into pre-existing production processes and established composite processing techniques including compression molding, vacuum bagging, roll wrapping and hand/automated layup.

Related Content

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)