JEC World 2019: Boston Materials

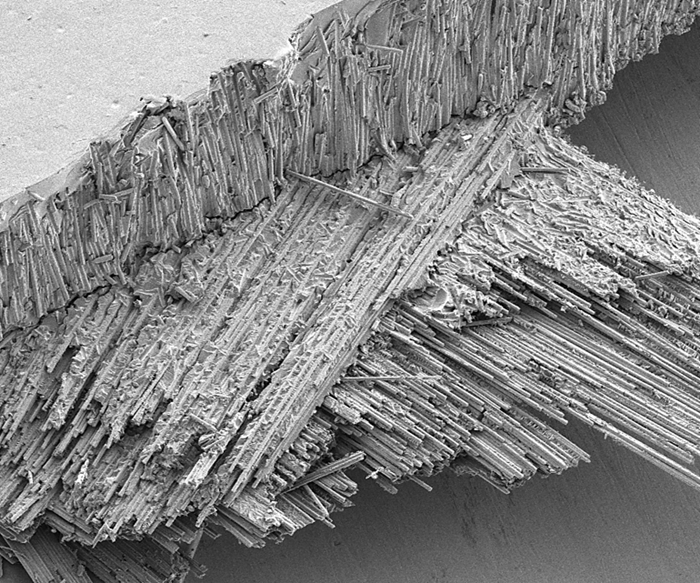

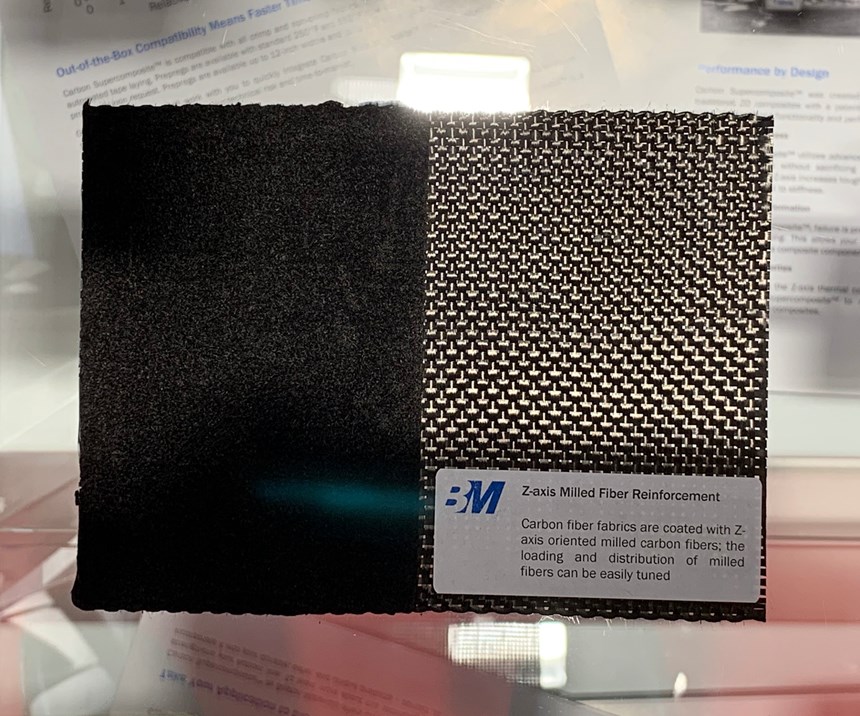

Boston Materials announced its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength.

Boston Materials (Bedford, Mass., U.S.) announced at JEC World 2019 the development of its Carbon Supercomposite, a carbon fiber fabric that features milled carbon fibers magnetically aligned in the “z” direction to provide uncommon ply-to-ply strength. Although Boston Materials is working with Sabic (Pittsfield, Mass., U.S.) to integrate Carbon Supercomposite with polyetherimide (PEI) and polycarbonate (PC), the fabric, says the company, is resin agnostic and compatible with any thermoset or thermoplastic resin matrix. Anvesh Gurijala, founder and CEO of Boston Materials, says Carbon Supercomposite can increase compressive toughness by as much as 300 percent and compressive strength by 35 percent compared to traditional prepreg systems. He said the company is initially targeting sporting goods and overmolding applications, but the material clearly has potential in a variety of end markets.

Related Content

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.