CAMX 2019 exhibit preview: Ingersoll Machine Tools

Ingersoll Machine Tools to highlight MasterPrint, Mongoose platforms at CAMX 2019.

Share

Read Next

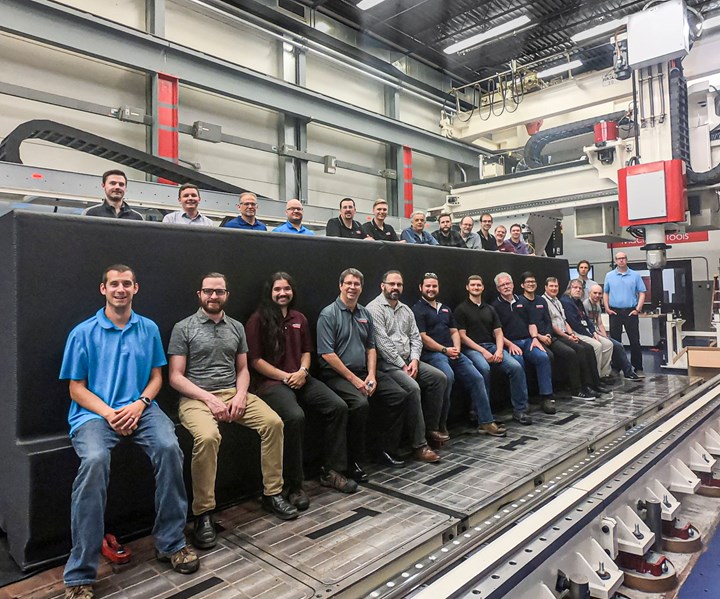

3D-printed hollow beam structure made with carbon fiber reinforced ABS using the MasterPrint platform at the Ingersoll Development Center. Source | Ingersoll Machine Tools

Ingersoll Machine Tools (Rockford, Ill., U.S.) will be highlighting a new achievement at CAMX 2019. The company’s Composite and Additive Team, in cooperation with the University of Maine, 3D-printed a hollow beam structure 276" long, 63" wide, 70" tall, made with over 4,750 pounds of carbon fiber reinforced ABS with its MasterPrint 3D printer at the Ingersoll Development Center.

MasterPrint is part of the Ingersoll family of wide and high 3D printers that offer the largest additive manufacturing volumes commercially available, and continue to set new records for the largest parts ever printed. Machine sizes begin at 12m for X-axis, 4m for Y-axis, and 2m for Z-axis.

MasterPrint offers the ability to seamlessly program, simulate, 3D print, and mill wide-and-high composite parts on a unique platform, driven by the Siemens 840D CNC.

MasterPrint has hybrid configurations that can be customized by selecting, among multiple modules:

-

3D Printing (150 – 500 – and soon 1000 lbs/h)

-

Five Axis Milling

-

Fiber Placement (1/8", 1⁄4", 1⁄2")

-

Tape Laying

-

Inspection

- Ultrasonic Knife

Also highlighted at the show will be Ingersoll’s Mongoose, its machine tool platform for delivering the most advanced Composites Automation in the world. Ingersoll has installations that provide for seamless quick exchange of head modules that afford the greatest amount of flexibility. Ingersoll delivers equipment to tackle highly complex shapes with high productivity performance. The Mongoose is driven by the Siemens 840D CNC.

Ingersoll Machine Tools’ Mongoose platform. Source | Ingersoll Machine Tools

Mongoose began as the fiber placement machine with the most compact end effector capable to tackle highly complex shapes with top productivity performance. It has evolved into a hybrid platform that delivers the most advanced composites automation in the industry through an array of automated quick exchange modules:

-

Fiber Placement (1/8", 1⁄4", 1⁄2")

-

Tape Laying (3", 6", 12")

-

ACSIS Inspection – including in situ

- Ultrasonic Knife

Preserving the original intentions, all Mongoose modules are compact and allow for superior performance on female tools, as well as high productivity on male tools. All are controlled via the Siemens 840D CNC.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

Isobaric double belt press is well suited to continuous production

CAMX 2023: Flexible and robust double belt presses from Held Technologie are adaptable to various base composite material requirements to produce top-quality, long-lasting products.

-

Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.