CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

This is Part 2 of a two-part compilation (see Part 1), which is comprised of 130+ solicited and received previews from CAMX 2023 exhibitors, showcasing the composites materials, processes, services and other technologies you can expect to see at the in-person event. Note that company names link directly back to the original preview article.

- Dixie Chemical: Dixie Chemical specializes in anhydride-based epoxy curing agents, including NMA.

- Johns Manville: In addition to its range of engineered fiberglass offerings, Johns Manville highlights its Neomera PA6 thermoplastic organosheets, which offer reinforcement versatility in addition to higher FVFs and better impregnation.

- Jrain FRP Co.: Jrain FRP, with locations in China, Mexico and the U.S., is equipped with 16 years’ of experience engineering, designing and manufacturing fiberglass-reinforced industrial products.

- Kennametal: The KenTip FS Modular Drill platform from Kennametal can help maximize efficiency with straight-bodied flutes, ultra-high polished chip flutes and smart wrench insertion.

- Kent Pultrusion: Kent Pultrusion is displaying its turnkey ServoPul servo-driven pultrusion lines and secondary equipment for handling composite profiles.

- Kingspan Insulation: Kingspan Insulation is highlighting its EPS composite and ISO-CF structural foam core, low-temperature pipe and mechanical insulation and sheet insulation solutions.

- KraussMaffei: KraussMaffei is featuring a variety of technologies, including Fiberform, ColorForm, RTM, extruder-based 3D printing and more.

- Kuris USA: Kuris USA introduces the single-ply “Cutty” series and Pattern Designer software that can be applied to composites, wood, foam, rubber, cloth and more.

- L&L Products: L&L Products is spotlighting its latest technology Phaster XP-607, a two-component, ambient temperature curing structural material for a range of applications.

- Langzauner: The multiprocess-capable press system from Langzauner Perfect seeks to set new standards in the processing and forming of composites.

- Macrodyne: Composite presses from Macrodyne are designed for high-volume production of compression molded parts.

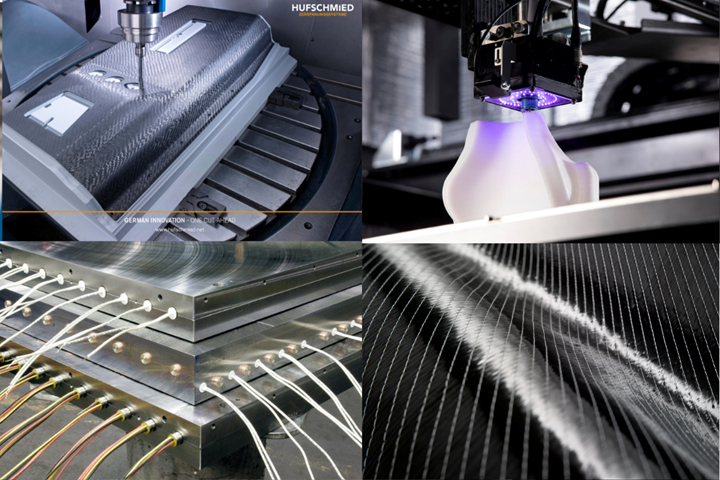

- Massivit 3D: The Massivit 10000-G, with gel dispensed printing offers an ultra-fast, sustainable and cost-effective way to digitize isotropic mold production for high-quality and more reliable composite parts.

- Matec Instrument Companies Inc.: Matec Instrument Companies highlights its strong commitment to integrate automation technologies into its nondestructive ultrasonic testing equipment for increased scalability, flexibility, quality and consistency.

- Matrix Composites: Matrix Composites is emphasizing its design and manufacture services for aerospace, defense, infrastructure and commercial/general aviation composite components and assemblies.

- Mikrosam: Mikrosam is featuring its modular, automated line solutions for towpreg production, filament winding, AFP and ATL to meet cost, flexibility and volume demands.

- Mito Materials: Mito's E-Go graphene additive provides strength, durability, flexibility, functionality and sustainability to fiber-reinforced composites and thermoplastics.

- Montalvo: Montalvo is introducing the new Zeus Multi-Zone Web Tension Controller with up to eight customizable tension control zones and the GR series of core chucks.

- Münch Chemie: Münch Chemie International, alongside distributor Fusoni, is introducing a new generation of semi-permanent release agents, essential auxiliary materials with fast evaporation.

- NanoXplore Inc.: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

- Netzsch Process Intelligence: Netzsch is exhibiting the sensXPERT Digital Mold, an integrated equipment-as-a-service solution that provides manufacturers with insight and process transparency into their operations.

- Nexx Technologies: Resin systems and prepreg architecture from Nexx Technologies help minimize out-time tracking as well as provide the ability to produce, ship and store finished rolls of prepreg without refrigeration.

- Olmar: Olmar introduces its “intelligent” autoclave, a combination of the company’s Industry 4.0 technology and its 75 years experience in autoclave and oven manufacture.

- Omni-NDE: Omni-NDE combines cobots/small robots with novel sensors to provide automated, contactless inspection of composites.

- Orson Resins India: Orson Resins India, a manufacturer and exporter of polyester resins, is featuring its complete range of resins and gelcoats for the composites, paints and coating industries.

- Park Aerospace: Park Aerospace is presenting its new aerospace-grade film adhesive material Aeroadhere FAE-350-1, in addition to other product offerings intended for aerospace, defense and spacecraft.

- Patz Materials and Technologies: Patz Materials and Technologies extends its prowess in space and aerospace innovations to a novel prepreg with a high char yield matrix, and Carbon-Carbon Cellular Core.

- Pelican Wire: Pelican Wire’s engineering and manufacturing capabilities provide tailored wire solutions for complex heating, temperature monitoring and distinct sensing applications.

- Plasmatreat: Openair-Plasma from Plasmatreat is a dry, non-contact, location specific and fast process, capable of being used across many industrial manufacturing processes.

- Plataine: Plataine’s Production Scheduler is an intelligent and intuitive solution that combines advanced tools and algorithms for a dynamic production planning approach.

- Practix: Family-owned and operated Practix USA is showcasing its complete line of industrial heat transfer equipment, including compression presses and conveyorized laminators.

- Precision Measurements and Instruments Corp.: Precision Measurements and Instruments Corp. is an ISO/IEC 17025-accredited testing laboratory that characterizes materials from cryogenic to elevated temperatures.

- Radius Engineering Inc.: Radius Engineering is presenting its highly automated Multi+ 2K Injection Systems equipment well-suited to RTM, SQRTM and VARTM processes.

- Rotaloc: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

- Roth Composite Machinery: Roth Composite Machinery focuses on automation, safety and time savings.

- Rudolph Bros. & Co.: Rudolph Bros. and Co. highlights its role as a prominent specialty chemical distributor and solutions provider with a display of high-performance adhesives, sealants, materials and more from well-known manufacturers.

- Saertex: Among Saertex’s offerings are 150-inch fabrics, powder binders and quick delivery of its Carbon Basic Line.

- Saint-Gobain Quartz: Saint-Gobain Quartz has evolved its business name to Saint-Gobain Advanced Ceramic Composites as it seeks to grow and diversity its quartz, ceramic continuous filaments and CMC businesses.

- Sekisu Aerospace: Sekisui Aerospace has developed thermoplastic technologies using its QForge process and continuous compression molding workcell to aid with endeavors in the aerospace industry.

- Smartech: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

- Specialty Materials: Specialty Materials enhances its Hy-Bor portfolio of prepregs containing boron and carbon fibers, which are used to selectively reinforce aerospace, space and sport goods applications.

- Stewarts of America: Stewarts of America offers precision tooling, machinery, equipment and contract converting services to perforate prepreg films, composite panels, laminates and more.

- Suase: Suase, under the Sanse Group, is presenting its design, development and manufacture of high-quality SMC/BMC/GMT/LFT molds for automotive, agriculture, construction, rail and more.

- Sutherland Presses: Sutherland Presses’ servo hydraulic press, backed by the I-Press three-in-one simulator for digital press control aim to revolutionize composites manufacturing.

- Svismold - Kunststoffwerk AG Buchs: Svismold invites CAMX attendees to witness how it is redefining the design and production of thermoplastic composites.

- SWORL: SWORL is highlighting its spray-fabricated reusable vacuum bags (membranes, foils) and a new sealing product for more sustainable, out-of-autoclave composites processing.

- Technology Marketing Inc.: Sprayomer Technology Amor-Vac RVBs, distributed by Technology Marketing, are said to be more efficient, sustainable, long-living and lighter in weight compared to sprayable silicone or nylon film alternatives.

- Teijin: Teijin Carbon America demonstrates its specialization in carbon fiber and other composite materials, including Tenax, Pyromex and Tenax ThermoPlastics lines.

- TE Wire & Cable LLC: TE Wire & Cable presents its high-performance temperature measurement, signal processing wire and cable solutions.

- TeXtreme: TeXtreme Gapped UD is a dry carbon fiber with controlled fiber gaps for improved resin infusion.

- Thermal Wave Imaging Inc.: High-precision, cost-effective thermographic NDT technologies offered by Thermal Wave Imaging addresses real-world inspection challenges.

- Thermo Fisher Scientific: Avizo Software, developed by Thermo Fisher Scientific is a visualization and analysis software for materials characterization and quality control.

- Tiger-Vac: The versatile TV-200 is among Tiger Vac's most popular models, used in a variety of applications with multiple substances.

- Thermwood: At the Thermwood booth, attendees can expect to see the LSAM Additive Printer system on display printing aerospace tooling, as well as Purdue’s Additive3D simulation module.

- Toray Group: Toray Group and its subsidiaries are bringing full-scale application examples to CAMX, highlighting the company’s vast composite material offerings.

- Trilion Quality Systems: Aramis, offered by Trilion Quality Systems, is a measuring system based on DIC and photogrammetry that enables full-field and point-based analyses for material and structural testing.

- Trimer Technologies: The nonhalogenated Harp Rapid resin system presented by Trimer Technologies achieves a low-temperature, tunable cure while attaining high mechanical properties, demonstrating its effectiveness in aerospace applications.

- Vartega: Vartega is exhibiting several examples of high-strength thermoplastic parts incorporating its recycled carbon fiber, as well as highlighting a recent collaboration with Mito Materials.

- Vectorply: Learn about the installation of a spread-tow machine at Vectorply’s headquarters that is capable of producing carbon fiber fabrics up to 100" wide, expanding the company’s new and standard width product capacity.

- Venango Machine: Venango Machine features MultiZone heating platens with a control system included, capable of reducing mold surface temperature variation by almost 400% during the compression molding process.

- Wabash MPI/Carver Inc.: The Genesis Series of hydraulic presses are for compression molding of rubber, plastics and composites.

- Walton Process Technologies: State-of-the-art, user-friendly PCS 2.0 showcased by Walton Process Technologies is an Industry 4.0 process control software for autoclaves, presses and ovens.

- Weber State University: The Master of Science in Systems Engineering program offered at Weber State University enables those enrolled a modular learning experience with industry-relevant content for career advancement opportunities.

- Wichita NIAR: ATLAS, part of Wichita State University’s NIAR, is an integrative manufacturing environment and engineering education program for advanced manufacturing R&D with state-of-the-art machines, software and processing options.

- Wisconsin Oven: Wisconsin Oven’s composite curing ovens are designed to meet customers’ specific process requirements, featuring consistent temperature, quick heating and recovery rates, reduced maintenance and IoT capabilities.

- Zünd: Zünd is exhibiting its heat-sealing module in operation with a G3 cutter configuration and Robot PortaTable 130 to emphasize its fully digital cutting capabilities from prepreg to thermoplastics.

Related Content

Digital chemistry platform leverages physics-based modeling for enhanced workflow

CAMX 2024: Schrödinger introduces a digital chemistry software platform, designed to enable researchers to tackle materials challenges across diverse polymer resin and carbon fiber applications.

Read MoreHigh-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreRead Next

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Read MoreBack in the composites saddle

The CompositesWorld team looks ahead to upcoming composites industry events and opportunities for the remainder of the year.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More