CAMX 2019 exhibit preview: SurfEllent

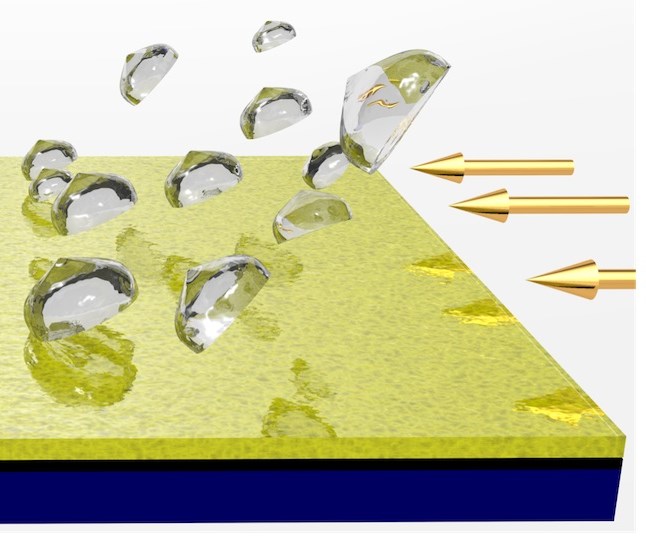

SurfEllent is featuring its anti-icing coatings, which are designed for high mechanical, chemical and environmental durability at a low cost.

Source | SurfEllent

SurfEllent (Houston, Texas, U.S.) is featuring its anti-icing coatings, which are designed for high mechanical, chemical and environmental durability at a low cost.

According to the company, anti-icing plays a critical role in protecting infrastructures, transportation, energy systems, and aircraft turbomachinery against the detrimental effects of icing. Despite the importance of anti-icing, the company says most coatings are ineffective for ice repellency and long-term durability.

SurfEllent's anti-icing coating technology is in the form of a liquid that reportedly can be applied to any surface, including polymers and ceramics. The liquid material can be packed in both cans and spray bottles depending on the desired end-use. The liquid coating in cans is applied through brushing, while the spray form is directly applied to a surface. Once applied on the surface, the liquid is said to cure in less than an hour, forming a solid and highly durable coating.

Related Content

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

-

Microwave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)