CAMX 2021 exhibit preview: Symmetrix Composite Tooling

Symmetrix highlights its capabilities to quickly produce precise, complex tooling for a variety of composites applications.

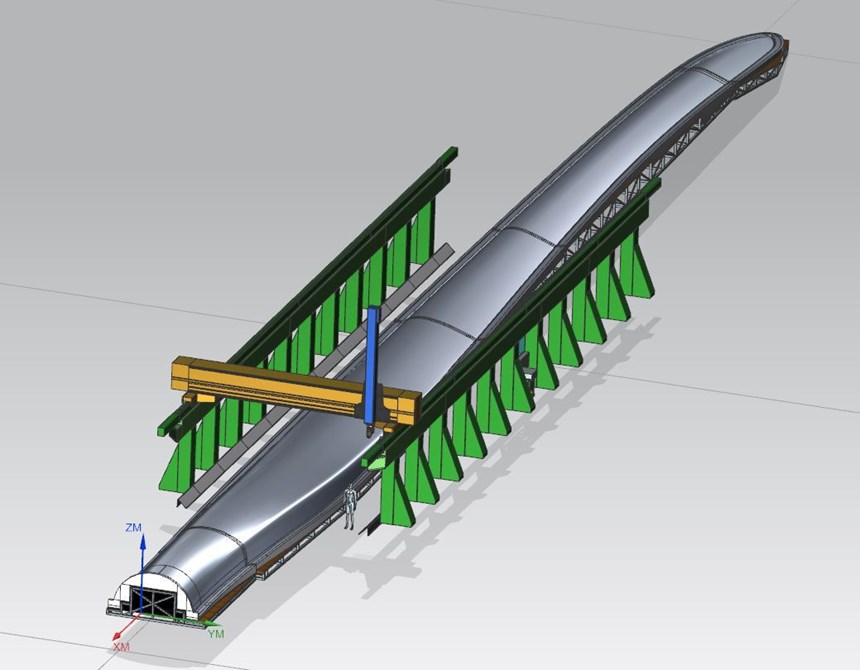

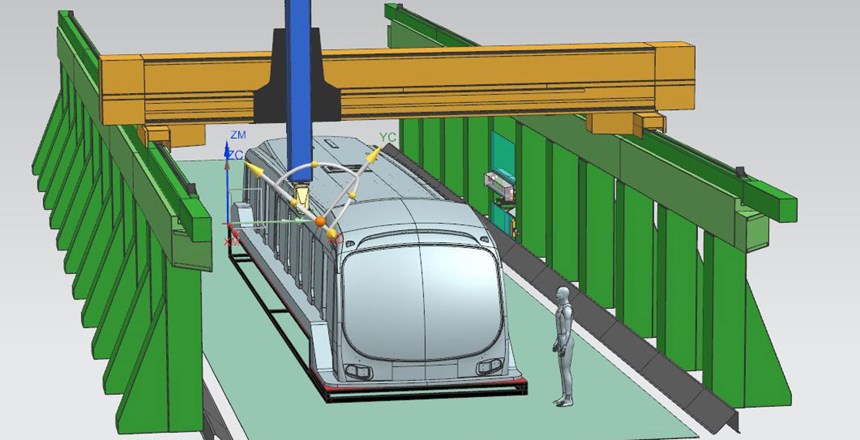

Symmetrix Composite Tooling (Bristol, R.I., U.S.) is a full-service composite tooling manufacturer that provides complex, innovative designs with precision and quality. Symmetrix combines sophisticated software, precision machining centers and expert craftsmen to ensure highly accurate tooling and fast delivery.

Symmetrix’s Composite Innovation Centers use advanced technologies to match exacting requirements on applications ranging from curved composite roof columns to America’s Cup racing yachts. Production tooling or limited-use prototype tooling can be optimized for the customer’s processing method at either ambient or elevated cure temperature.

According to John Barnitt, president of Symmetrix, the company can achieve sub-millimeter accuracy (± 0.020) through subtractive machining methods in low-shrink materials that do not absorb moisture. He adds that their molds are adequately supported, vacuum-tight geometries that can support closed mold resin infusion

Related Content

-

Proper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Metal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)