CAMX 2022 exhibit preview: Teubert

Teubert highlights enhancements made to its continuous compression molding (CCM) system, including production scale-up, reducing required energy during production, live measurement of pressure distribution.

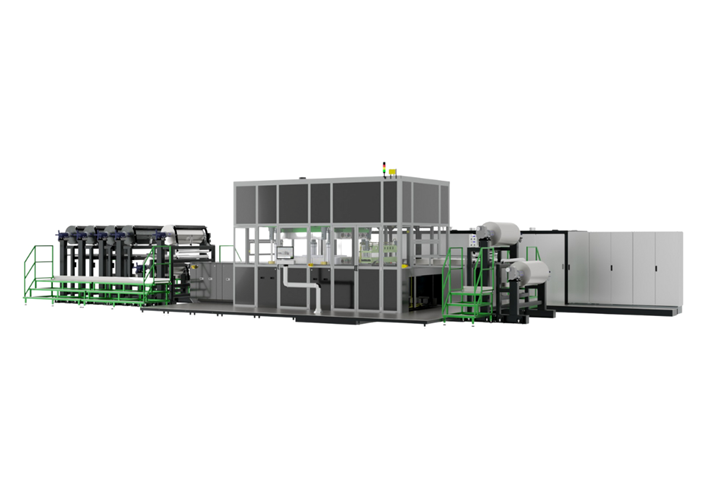

Whether prefabricated organosheets, or long, straight or curved profile (e.g., U, I, T, L) structures, Teubert Maschinenbau GmbH (Blumberg, Germany) says it has been supplying production equipment at the highest technological level for 15 years with its continuous compression molding (CCM) technology.

The CCM technology enables endless production for composite consolidation, Teubert reports. Fibers of all types can be processed with the full range of thermoplastic polymers. Raw materials can be fed as fiber fabric mats and polymer films in the film stack process, including prepreg fabrics, powder prepregs, unidirectional (UD) prepregs or hybrid fabrics.

Using CCM, raw material is pulled in several adjustable strokes through the consolidation unit, which opens and closes cyclically. Pressure distribution through consolidation can be adjusted to specific materials at several positions and controlled precisely. The composite then passes through a material-specific temperature profile consisting of several heating and cooling zones; temperatures of up to 500°C are possible in the heating zone.

Semi-finished products produced by the CCM process are said to feature a porosity level well below 1% with a very low dimensional tolerance.

In order to meet new demands for higher production volumes at consistently high laminate quality and higher production efficiency, Teubert recently revised its CCM technology, scaling up production.

Last year, the first CCM line for the production of organosheets with a production width of 1,300 mm (50") was put into operation. The line has a consolidation unit with an area of 1,300 x 2,100 mm with a maximum pressing force of 820 tons at a production speed of 150 m/h. As a result of increasing energy costs and CO2 emission reduction goals, further developments have also focused on reducing required energy during production.

Moreover, to further optimize the machine’s pressure distribution to achieve good laminate consolidation, a system has been developed that enables live measurement of the pressure distribution at different positions of the consolidation unit. This measurement technology can be integrated into the consolidation unit and enables permanent monitoring during production, Teubert says.

However, monitoring the pressure distribution alone only provides increased quality monitoring, or enables adjustments to be made to the production tool after production. Here, Teubert says its CCM technology goes one step further. With the aid of an Adaptive Consolidation Unit in conjunction with an innovative new tool design, it is possible to deform the production tool three-dimensionally during production and thus measure and adjust the pressure distribution online. This enables the impregnation speed to be increased on the one hand and the laminate quality to be significantly improved on the other.

Related Content

-

Commingled yarn solutions provide flexible thermoplastic prepregs

CAMX 2024: Concordia Engineered Fibers presents customizable commingled yarn solutions, including environmentally friendly options.

-

Wireless strain measurement system for die-cast and injection molding

CAMX 2023: Gefran introduces the QE2008-W, a non-invasive, magnetically mounted strain solution with Bluetooth transmission that uses sensors to accurately measure and maintain equipment quality.

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.