Diab and Porcelanosa Group create lightweight composite panel

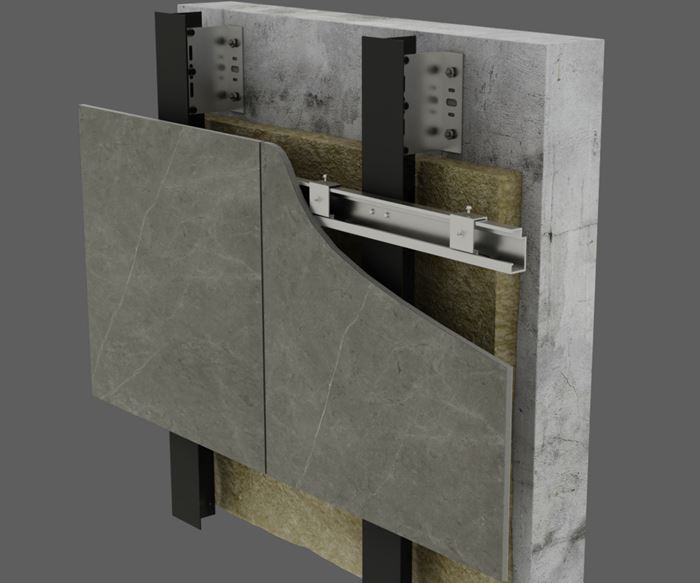

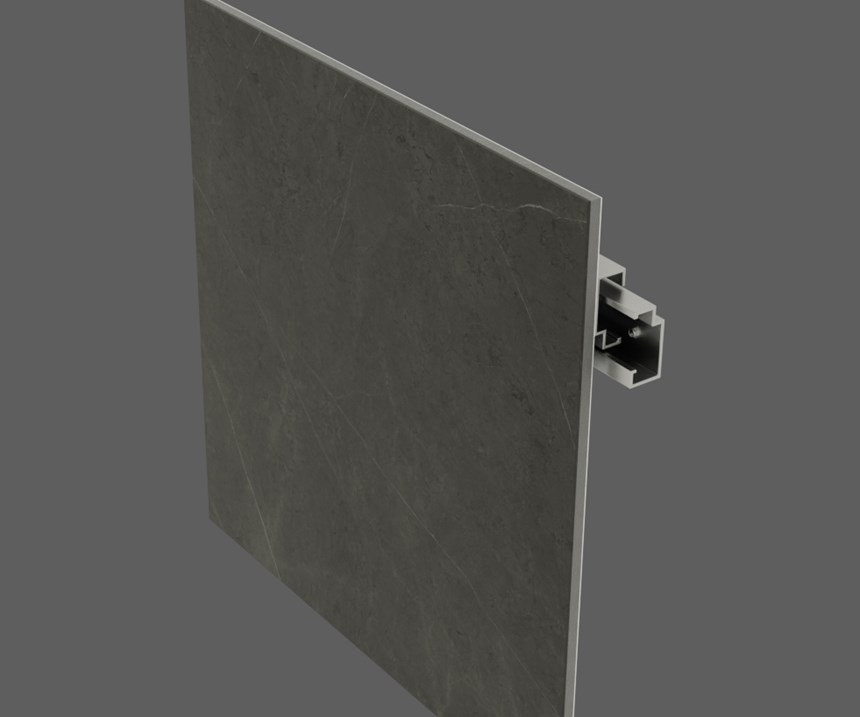

The building panel comprises ceramic and aluminum layers with a Divinycell P core.

Diab (Helsingborg, Sweden), in collaboration with Butech, a materials and building systems division of ceramic tile manufacturer the Porcelanosa Group (Villarreal, Spain), has developed a new foam core sandwich panel for use with lighweight composite panels.

The light sandwich panel system, called System X light XXL, has been developed as a fixing solution for building façades. The panel comprises a ceramic facing and an aluminum backside with a core of Divinycell P that ensures improved thermal insulation and complies with the FST (Fire, Smoke and Toxicity) classification Euroclass Bs2d0. The panel’s dimensions are 3,000 by 1,000 mm, and it weights 8 kg/m2 .

Due to its light weight, the panel is said to offer faster installation and decreased need for a back-up structure. The ceramic finishing is said to achieve a stable and even surface, and the panel is designed to ensure no change in color over time and to reduce the risk of warping due to thermal stresses.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

.jpg;width=70;height=70;mode=crop)