IDI International launches material solution for EV battery covers

IDI Composites International is introducing FLAMEVEX, a new family of fiber reinforcements and resins designed specifically for the manufacture of battery enclosure systems.

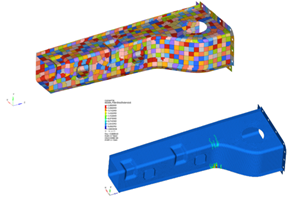

IDI Composites International EV battery enclosure manufactured with FLAMEVEX. Source | IDI

IDI Composites International (Noblesville, Ind., USA) is introducing FLAMEVEX, a new family of fiber reinforcements and resins designed specifically for the manufacture of battery enclosure systems for the electric vehicle (EV) and new energy vehicles (NEV) market.

The FLAMEVEX family of products, which include chopped glass fibers combined with either unsaturated polyester (UPR) or a combination of UPR and vinyl ester, has been used on battery packs that have passed the stringent Chinese Standard GB/T 31467.3 test, commonly known as the “Chinese bonfire test.” FLAMEVEX, says IDI, offers designers a strong, lightweight and cost-effective alternative to steel and aluminum materials traditionally used to enclose battery packs in EVs and NEVs.

Ramon Rodriguez-Irizarry, vice president and group director for electric vehicle market development at IDI, notes that EV battery pack design, configuration and location are currently not standardized and vary greatly from OEM to OEM. Because of this, the cost, dimensions, wall thickness and flame-retardant requirements of battery pack enclosures vary as well. FLAMEVEX, therefore, is being offered by IDI as a custom-compounded combination of fibers, resins and fillers designed to meet the customer’s application specific requirements.

FLAMEVEX is produced by IDI in a format that allows it to be processed like a sheet molding compound (SMC), but Rodriguez-Irizarry is quick to point out that the bespoke nature of the FLAMEVEX chemistry distinguishes it from traditional SMCs. He also notes that it will be possible, soon, to co-mold FLAMEVEX with continuous fiber preforms. Further, although the FLAMEVEX family currently uses chopped glass fiber, Rodriguez-Irizarry says carbon fiber is an option as well, but the cost penalty it brings limits its feasibility.

Working in collaboration with OEMs and Tier 1 partners, IDI FLAMEVEX materials have been used on battery packs which have passed the Chinese bonfire test at wall thicknesses as small as 2.5 mm.

“Thermoset composites represent an ideal replacement for metals in these kinds of battery enclosures,” noted Yves Longueville, general manager for IDI Composite Materials (Shanghai) - China. “Thermoset materials can be formed into complex shapes and they are also strong and lightweight. Beyond these benefits, a high level of fire performance distinguishes FLAMEVEX from traditional SMC composites,” Longueville explained. “FLAMEVEX maintains its impressive fire performance even at low thicknesses and without compromising the strength or moldability of the compound. It is the best choice for designers who aim to delight EV consumers with high-performing and affordable products.”

IDI says the market for EV and NEV vehicles is growing exponentially, with sales expected to double in 2020, reaching 4 million new cars globally. “As cost of ownership goes down, range increases and emissions requirements become tighter, electric and alternative fuel vehicles are only becoming more attractive to buyers,” says Rodriguez-Irizarry. “With FLAMEVEX, we’re not only helping to meet a need for OEMs and designers, we’re introducing a material that contributes to the strength, safety and affordability of this next generation of vehicles for consumers around the world.”

IDI Composites International says FLAMEVEX is available internationally via its locations in the United States, Mexico, Europe and Asia.

Related Content

SMC simulation tool enhances design optimization

CAMX 2023: FiRMA, Engenuity’s new approach to SMC, uses a predictive technique that accurately reflects material properties and determine the performance range an SMC part or structure will exhibit.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreMatrix Composite highlights carbon fiber SMC prepreg Quantum-ESC

Prepreg produced by LyondellBasell features high flow, rapid tool loading capabilities.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)