Mag7 Technologies offers advance licensing for graphene CMC technology

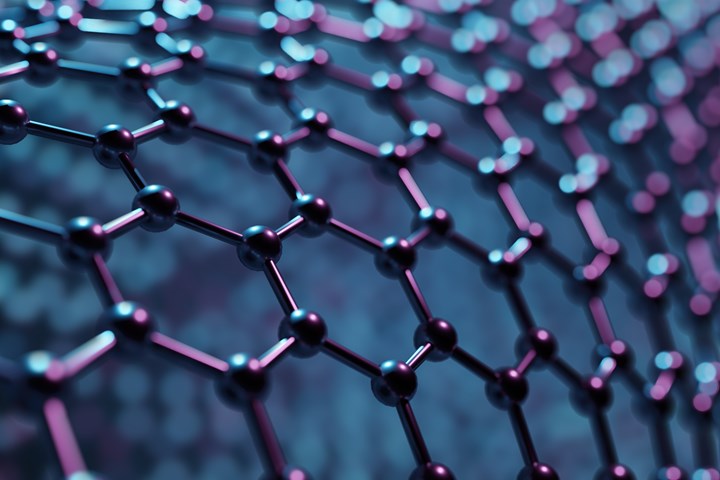

The company’s process produces graphene-enhanced ceramic precursor for use in ceramic matrix composite (CMC) applications.

Mag7 Technologies LLC (Medford, Ore., U.S.) has begun advance licensing of its technology for making polymer-derived, graphene-reinforced ceramic matrix composites (CMC). Trademarked CeraGraphe, the ceramic-graphene slurry produced from the process can be used in a variety of CMC applications, particularly where extreme heat is an issue.

Traditionally manufactured CMC parts like ceramic brakes and bolts, the company says, resist heat extremely well, but their mechanical properties diminish as they wear, requiring frequent replacement. Graphene reinforcement is said to increase the structural integrity and performance of these parts.

According to Mag7 Technologies, the company’s process significantly reduces the production cost of graphene in CMCs, because instead of requiring the purchase of graphene, the process renders its own graphene out of less expensive graphite through an in situ process. The resulting graphene is then dispersed uniformly in the composite, and is covalently bonded to the ceramic precursor throughout the matrix. CeraGraphe is said to be relatively inexpensive and highly adaptable, and can be applied to any preceramic polymers, such as polysilazane.

The process was developed by Alexander Lukacs, Ph.D., and Lucas Marin, Mag7 principals serving as Mag7’s primary science and technology advisers. Over their careers, they have invented many successful chemistries, some of which have been used in high-profile technology projects or which have resulted in well-known popular brands.

Mag7 now offers licenses to apply the CeraGraphe process to any CMC. The company is not a ceramics manufacturer and does not sell physical product other than small testing quantities of CeraGraphe “slurry” produced in its Oregon laboratory. Manufacturers can order limited quantities to test before purchasing a license to use the process.

The process is patent pending as “POLYMER-DERIVED, GRAPHENE REINFORCED CERAMIC MATRIX COMPOSITES,” U.S. Provisional Patent Application No. 63/211,545 to Lukacs (III) et al., filed June 16, 2021.”

In addition, Mag7 is seeking collaborations with engineering labs and academic institutions interested in furthering uses for this chemistry.

Related Content

-

General Atomics wins DOE contract to develop silicon carbide CMC for fusion power plants

GA-EMS will leverage experience with SiGA SiC/SiC cladding for nuclear fuel rods to develop new SiC composite foam and other materials for fission and magnetic fusion programs.

-

MATECH C/ZrOC composite is deployed in hypersonic aeroshells

Ultra high-temperature insulating CMC targets hypersonics, space heat shields and other demanding applications, tested up to 2760°C under extreme stagnation pressures.

-

Developing milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)