General Atomics wins DOE contract to develop silicon carbide CMC for fusion power plants

GA-EMS will leverage experience with SiGA SiC/SiC cladding for nuclear fuel rods to develop new SiC composite foam and other materials for fission and magnetic fusion programs.

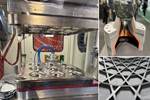

The fuel rod cladding, reactor core and core structures in advanced nuclear reactors are manufactured from GA-EMS' SiGA, a high-tech ceramic matrix composite (CMC) that can withstand more than twice the temperature of metal components used in current reactors. Source | General Atomics Advanced Reactors and U.S. DOE Office of Nuclear Energy

General Atomics Electromagnetic Systems (GA-EMS, San Diego, Calif., U.S.) has been awarded a 3-year contract from the U.S. Department of Energy (DOE) Office of Science to develop a scalable, cost-competitive path to manufacture silicon carbide (SiC) and SiC composite foam materials for advanced fusion power plants.

“SiC and SiC foam will provide significant advantages in both efficiency and longevity to support fusion power plant applications,” states Scott Forney, president of GA-EMS. “Foam made of SiC is a highly effective insulator that prevents unwanted heat transfer and is extremely resistant to radiation compared with other insulating materials that degrade over time. Our manufacturing method allows us to finely control the properties of the material and provides a cost-effective approach for the fabrication of SiC foam specifically engineered for the fusion environment.”

GA-EMS’ engineered Accident-Tolerant Fuel (ATF) rod cladding is a multilayered composite design comprising SiC fiber in a SiC matrix. Source | General Atomics ATF

SiC has been used for a wide variety of industrial purposes for more than 100 years. Its high hardness and ability to survive extremely high temperatures makes it ideal for demanding applications such as cutting tools, refractory components, high-power electrical systems and nuclear energy applications, such as coating fuel particles. However, its brittleness in pure form limits its use as a structural material. Reinforcing with SiC fibers significantly toughens the ceramic, creating a SiC/SiC ceramic matrix composite (CMC). Still, difficulties in manufacturing, as well as problems with joining CMC components, has made more widespread deployment in nuclear applications impractical.

GA-EMS says it has decades of experience working with SiC and began its current work on CMC for nuclear fuel cladding in 2009. Leveraging past research with new technologies, GA-EMS scientists have developed SiGA, a high-tech engineered SiC CMC that is the DOE’s material of choice for its Accident-Tolerant Fuel (ATF) program, which is developing nuclear reactor fuel rods that can survive temperatures far beyond that of current materials. GA-EMS is also developing SiGA components for applications beyond ATF.

GA-EMS has developed SiGA and other advanced materials for nuclear applications. Source | General Atomics Advanced Materials

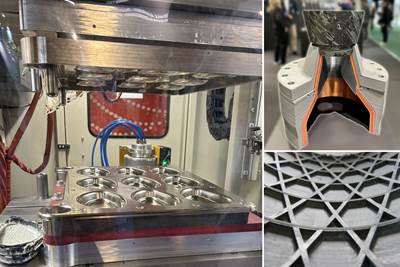

GA-EMS can fabricate SiGA composites in complex planar, tubular and custom geometries, but also has developed a proprietary joining method that can bond SiC to itself and other materials, in a variety of configurations. Such joints retain their integrity and hermeticity at high temperatures, pressures and neutron fluences. Finished SiGA composites maintain their strength and stability under high levels of irradiation up to temperatures well above 1600°C.

SiGA composite components are available in tube diameters from 5 to 50+ millimeters and tube lengths up to 1 meter. Hot-pressed SiGA structures with thickness >25 millimeters can also be produced, and both blind and through-hole features can be manufactured in near-net shape without machining.

This foam core CMC developed by NASA features woven SiC and carbon fibers, which allows in-plane heat dissipation. Source | NASA, Tech Briefs

Now, GA-EMS will leverage its high-temperature ceramic fabrication and fusion test facilities to demonstrate the path toward manufacturing first-of-kind SiC and SiC foam materials.

“We are developing the path forward to customize and test our SiC materials and composites at the dimensions, scale and performance metrics required for application to fission and magnetic fusion programs in support of future nuclear power plants,” says Christina Back, vice president of GA-EMS Nuclear Technologies and Materials.

General Atomics announced its concept for a fully integrated fusion pilot plant in October 2022. The concept uses SiC–based materials that can withstand the intense conditions within a high-power fusion device. “Advanced materials like SiC and SiC composites will increase efficiency, reduce waste, and make fusion facilities more cost effective,” notes Brian Grierson, director of General Atomics’ Energy Group’s Fusion Pilot Plant Design Hub.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreHow composites have become a necessity

Composites used to be one of many material options across industries and applications, but that's not the case anymore.

Read MoreDrag-based wind turbine design for higher energy capture

Claiming significantly higher power generation capacity than traditional blades, Xenecore aims to scale up its current monocoque, fan-shaped wind blades, made via compression molded carbon fiber/epoxy with I-beam ribs and microsphere structural foam.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreRead Next

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read More