NatureWorks Ingeo 3D700 biopolymer reduces LSAM warpage, minimizes print failures

Testing by NatureWorks’ global partners demonstrates a shrink rate less than 0.25% in printed parts and obtainable lower print temperatures due to optimized melt viscosity and microstructure.

Share

Read Next

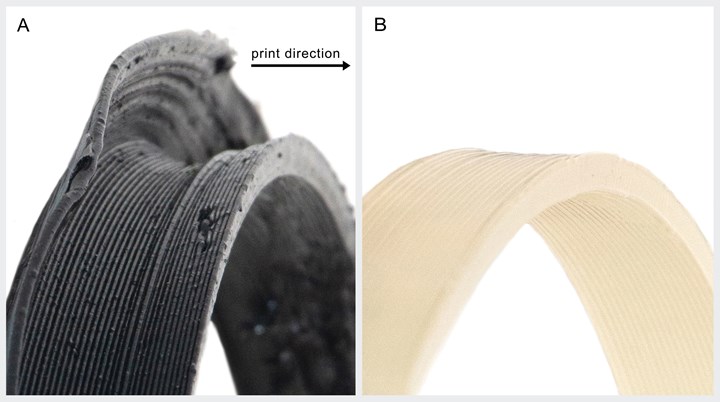

Part (A) in black printed with polypropylene (PP) shows notable warpage in the side wall compared with the same part (B) printed with clear Ingeo 3D700 even when print conditions were optimized for each material. Parts courtesy of Dyze Design.

NatureWorks (Minnetonka, Minn., U.S.) continues to grow its portfolio of Ingeo biopolymers designed for additive manufacturing (AM) with the introduction of Ingeo 3D700, a new PLA grade for use in large-format additive manufacturing. NatureWorks notes that monofilaments made with this PLA grade, broadly used in the desktop 3D printing market, have shown notable performance characteristics such as precise detail, good adhesion to build plates with no heating needed, reduced warping or curling and low odor while printing. These properties are said to make Ingeo 3D700 ideal for 3D printing using many different types of printers and for a broad range of printing applications from consumer-level to industrial applications.

In large-format printing, the higher rate and volume of polymer deposition can quickly result in excessive warpage with certain materials, like ABS, or significant shrinkage as with some polyolefins or some general-purpose PLA grades. Warpage pulls the part away from the print bed or causes layer separation, resulting in failed prints. Controlling the polymer-microstructure, NatureWorks’ amorphous PLA grade, Ingeo 3D700, offers a low material shrink rate, which reduces warpage, improves gap fill and adhesion and ensures successful prints.

Further, the need for added reinforcements such as mineral fillers, glass, carbon or cellulosic fiber to reduce part warpage have been minimized. If a specialty print requires additional reinforcement, then cellulose-based additives are easily compounded with Ingeo 3D700, creating a bio-based compound alternative to high-cost petrochemical-based compounds such as carbon fiber ABS.

According to NatureWorks, multiple partners evaluated Ingeo 3D700 for use in large-format fused filament fabrication (FFF) and direct resin-to-print processes with positive results. For example, in addition to going one step further towards reducing warpage in large-format prints beyond previous Ingeo PLA grades designed for 3D printing, Polymaker (Shanghai, China), a leading manufacturer of 3D printing material and filament measured improved Z-layer adhesion when printing with Ingeo 3D700.

Dyze Design (Quebec, Canada) an extruder designer and supplier of components for large-format printers, ran print tests comparing Ingeo 3D850, a grade already known for its low-shrink characteristics, and Ingeo 3D700. The tests, according to the company, indicate that a large-format part printed using Ingeo 3D850 demonstrated a shrink rate of 1.25%. In comparison, the same part printed with Ingeo 3D700 had a shrink rate of less than 0.25%. Retaining a higher throughput rate, Dyze Design was also able to successfully print at a lower temperature of 190ºC without seeing shrinkage or warpage in the part.

Filament manufacturer, MCPP (Helmond, Netherlands), conducted printing tests using filament made from Ingeo 3D700 and demonstrated a 11-13% increase in flow rate due to the optimized melt viscosity, compared to a general-purpose PLA. According to MCPP, this resulted in improved gap fill and adhesion between perimeter layers, suggesting its suitability for fused granular fabrication (FGF) 3D printing.

Ingeo 3D700 is now available for use as resin pellets for direct resin-to-print processes or as filament for FFF process in the U.S., Asia, and Europe.

Related Content

European SUSPENS project targets green composites production

The 13-partner program will addresses the challenge of reducing the environmental footprint of sandwich and hollow composite structures via bio-sourced resins and carbon fiber precursors.

Read MoreBiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreOkom wrks labs works with Autodesk for mycelium-based composite commercialization

Research Residency program will further refine material properties and manufacturing processes to support the startup’s efforts of providing high-performance, regenerative biocomposite solutions.

Read MoreSuper Resin Inc. highlights plant-based epoxy resin, foam core

Eco-friendly resin system using glycol lignin offers an eco-friendly option for CFRP structures and components, and core materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)