New thermoset matrix resin offers fast, low-temp, tunable cure

HARP Rapid is a new thermoset resin chemistry for liquid molding processes that offers a fast, tunable cure profile, and a Tg that exceeds the material’s cure temperature.

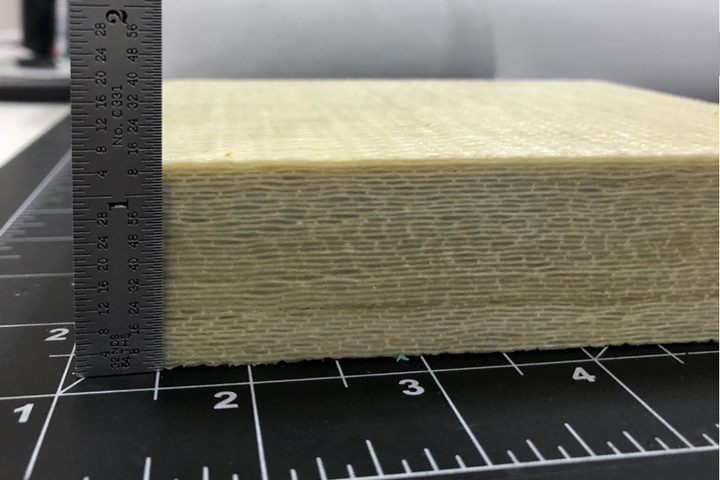

This laminate molded with Trimer’s new HARP Rapid resin shows the thickness capabilities with this fast-cure, high-performance matrix resin. Photo Credit: Trimer Technologies

Trimer Technologies LLC (Ann Arbor, Mich., U.S.) has introduced HARP Rapid, a new thermoset resin chemistry for liquid molding processes that offers a fast, tunable cure profile, and a Tg that exceeds the material’s cure temperature. Henry Sodano, president of Trimer, says HARP Rapid’s proprietary chemistry is one-part catalyzed and processes like a vinyl ester, but offers a distinctly different processing and performance profile. HARP Rapid can be cured very quickly at temperatures between 100-140°C, Sodano says; 3-mm thick structural panels cure in about 30 seconds while parts up to 30 mm thick require as little as 120 seconds. HARP Rapid also has a low room-temperature viscosity of 200 cP, but drops to just 20 cP at a 65°C injection temperature, which, Sodano says, when combined with the snap cure, can enable drastic reductions in cycle times when used with high-pressure resin transfer molding (HP-RTM) or other liquid molding processes.

Trimer has also developed the technology to tune the gel time, allowing the heated resin to maintain a low viscosity and thus enabling pre-cured resin flow into larger or multi-cavity molds prior to snap curing. HARP Rapid also offers a long gel time at ambient temperature, enabling its use in vacuum-assisted RTM (VARTM) or in filament winding and pultrusion processes using resin bath systems. Sodano says Trimer has demonstrated pultrusion speeds up to 10 ft/minute. Further, Sodano says the glass transition temperature has been de-coupled from the cure process, offering a dry Tg of 225°C without a post cure.

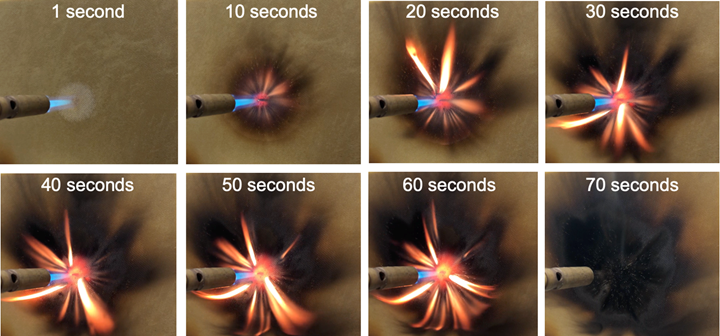

Flame exposure performance for Trimer’s HARP Rapid resin system. Photo Credit: Trimer Technologies

Other features of HARP Rapid include demoldability at 140°C, a CTE of 29 ppm/°C, low VOC content, E-Coat stability, non-flammability after cure, FAR 25.853 compliance, 14 CFR 25.853 OSU heat release certification, 108 MPa tensile strength, 4.1 GPa tensile modulus, 139 MPa flex strength and 149 MPa compression strength. Sodano says the resin provides the properties found in aerospace epoxies, but with cycle times below state-of-the-art automotive polymers.

Potential applications for HARP Rapid include automotive body-in-white (BIW) structures, automotive chassis components, pultruded spar caps for wind turbines, aircraft interiors, battery enclosures, missile bodies and UAM aircraft structures. The resin is in trial with several customers in a variety of end markets. Sodano says Trimer currently has capacity to produce more than 1 million lb/year of HARP Rapid, but the company is evaluating expansion options. He also reports that the resin is cost-competitive with many of the resin systems commonly used in composites manufacturing. Sodano adds that Trimer is developing a prepreg formulation of HARP Rapid, as well as a formulation that is compatible with sheet molding compound (SMC) use. Trimer is funded in part by two U.S. Small Business Innovation Research (SBIR) Phase II grants — one focused on use of HARP Rapid in a defense application, and the other focused on use of HARP Rapid in HP-RTM.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.