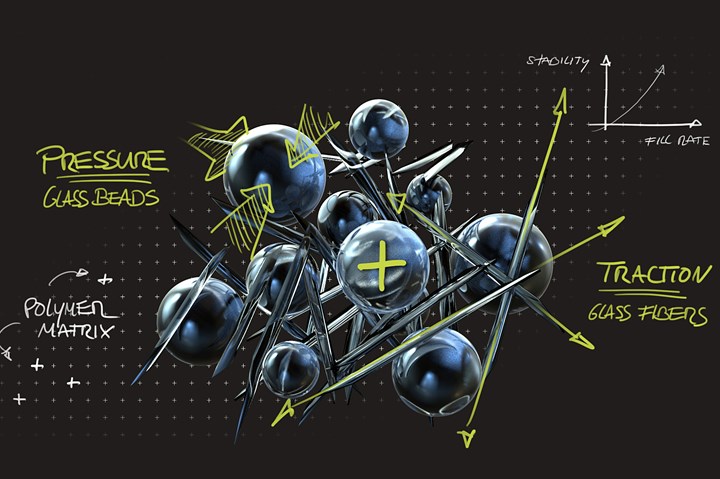

Swarco glass filler beads enable 3D printing material optimization

A range of tailor-made glass filler beads for additive manufacturing help improve the properties of 3D printing base materials, including composites.

A range of tailor-made glass filler beads developed by Swarco Advanced Industry Systems (Amstetten, Austria) enable the properties of 3D printing base materials to be individually modified and optimized according to individual parameters. Adding them simultaneously increases the hardness and creep behavior of the basic material, according to Swarco. Glass filler beads give molded parts a higher density and contribute to reducing material costs, thanks to the highly efficient production process with a small carbon footprint. They are also ideal solutions in the use of 3D-printed parts.

Swarco Advanced Industry Systems is part of the international Swarco Group and uses the universal benefits of glass beads for special industrial applications. What began in 1969 as a business producing small reflective glass beads for road markings has evolved into a leading manufacturer of micro glass beads, with production sites in Europe and the U.S. Micro glass beads serve as a high-grade filler material in industrial applications, as well as the composites industry, and as a blasting abrasive for surface treatments.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.