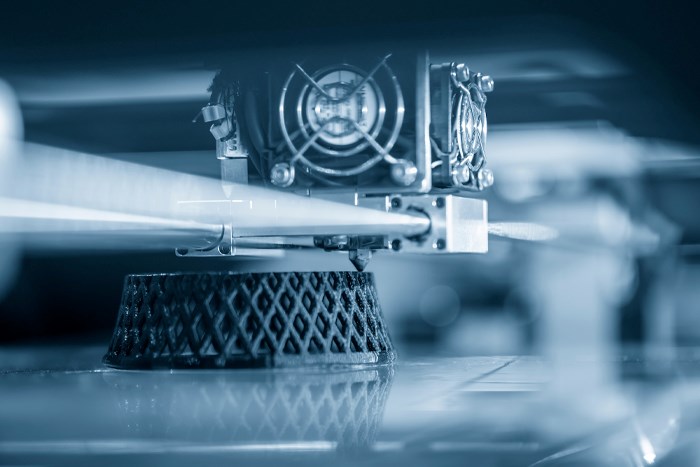

Xenia Materials reveals composite materials for FDM printing

A new range of 3D printing materials are formulated for use on any pellet-based fused deposition modeling printer.

Photo credit: Xenia Materials

Xenia Materials (Mussolente, Italy) has announced a new range of 3D printing materials, comprised of resins combined with chopped fibers and additives. The materials are made for use in any pellet-based fused deposition modeling (FDM) printer, for large-scale additive manufacturing (LSAM) as well as high-precision production.

Xenia will offer materials dedicated to 3D printing based on its existing range of product families: Xecarb, Xebrid, Xelight and Xegreen. The Xecarb 3DP brand includes carbon fiber-reinforced PEI, ABS and PC. Xebrid 3DP includes a glass and carbon fiber-reinforced ABS. Xelight 3DP includes a lightweight polyether block amide (PEBA), and Xegreen 3DP includes carbon fiber-reinforced PA6 and PA66. According to Xenia, the materials are recyclable and suitable for a wide range of applications and markets including industry, sport, sustainable mobility and defense.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

.jpg;maxWidth=300;quality=90)