Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Editor’s note: This content was originally published on NetComposites.com. NetComposites was acquired by CompositesWorld’s parent company, Gardner Business Media, in February 2020.

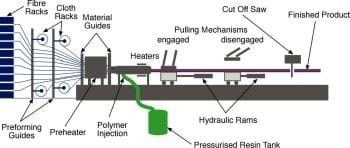

In a pultrusion process, fibers are pulled from a creel through a resin bath and then on through a heated die. The die completes the impregnation of the fiber, controls the resin content and cures the material into its final shape as it passes through the die. This cured profile is then automatically cut to length. Fabrics may also be introduced into the die to provide fiber direction other than at 0 degrees. Although pultrusion is a continuous process, producing a profile of constant cross-section, a variant known as “pulforming” allows for some variation to be introduced into the cross-section. The process pulls the materials through the die for impregnation, and then clamps them in a mold for curing. This makes the process non-continuous, but accommodating of small changes in cross-section.

Material options include generally any epoxy, polyester, vinyl ester or phenolic resin combined with any fiber type. Core materials are not generally used.

Advantages to pultrusion include:

- This can be a very fast, and therefore economic, way of impregnating and curing materials.

- Resin content can be accurately controlled.

- Fiber cost is minimized since the majority is taken from a creel.

- Structural properties of laminates can be very good since the profiles have very straight fibers and high fiber volume fractions can be obtained.

- Resin impregnation area can be enclosed thus limiting volatile emissions.

The disadvantages include that the process is limited to constant or near constant cross-section components, and costs for heated dies can be high.

Typical applications include beams and girders used in roof structures, bridges, ladders and frameworks.

For the latest on pultrusion and its applications, see compositesworld.com/zones/pultrusion.

Related Content

-

Novel processes for hybrid thermoset-thermoplastic pultruded parts

CFRP pultrusion and pullwinding specialist Epsilon Composite combines thermoplastic overmolding with traditional thermoset processes, demonstrated through aircraft struts and industrial applications.

-

Pultrusion, pull-winding showcase high-volume composites production

JEC World 2024: Exel Composites offers attendees a chance to engage with company experts and learn more about continuous composite manufacturing processes across various industries.

-

Exel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.