Search Results

Showing 31 – 40 of 2660 results

High-pressure gas storage vessels represent one of the largest and fastest-growing markets for advanced composites, particularly for filament-wound carbon fiber composites. Although they are used in self-contained breathing apparatuses and provide oxygen and gas storage on aerospace vehicles, the primary end markets are for storage of liquid propane gas (LPG), compressed natural gas (CNG), renewable natural gas (RNG) and hydrogen gas (H2).

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

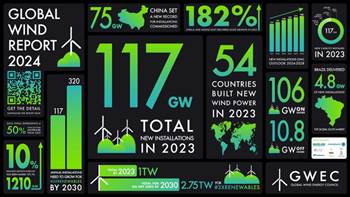

Global Wind Report describes a record year for wind energy in 2023, but highlights the need for policy-driven action to meet COP28 and 1.5°C pathway targets.

American Clean Power Association latest findings indicate that 2024’s second quarter of solar, energy storage and wind additions will set the stage for a record year.

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Versatile composites equipment will support the global R&T organization’s research and manufacturing of novel materials and parts for pressure vessels and pipes.

After an expected slow start to 2024 with low sales in the first quarter, Gurit saw a stronger second quarter with net sales of ~$246.7 million, driven by the ramp-up of new wind blades and higher demand in non-wind markets.

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

Composite pressure vessel supplier contributes to 75-meter vessel that will be powered by wind and solar power and features advanced power systems like hydrogen.

New aircraft is expected to deliver wind turbine blades from 105 meters up to expand the reach of wind energy and achieve global climate goals.

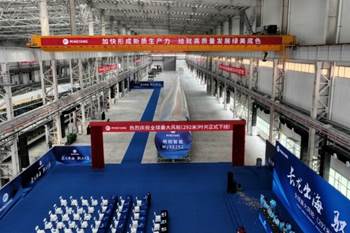

First MySE292 offshore wind blade from MingYang Group successfully rolled off the production line in February.