Aerospace

Safran NacelleLife service agreements support LEAP engine MRO

Safran has signed a NacelleLife agreement with Saudia and Tarmac Aerosave for Airbus fleet maintenance, including engineering services and availability of critical components.

Read MoreBoom Supersonic announces aircraft, engine and investment milestones

New strategic investment from NEOM comes as XB-1, Symphony and Overture achieve important program turning points.

Read MoreQarbon Aerospace welcomes new CEO Michael Canario

Canario’s 35-year career in aerospace, defense and advanced materials will continue to propel Qarbon’s growth initiatives in composite structures for the aerospace industry.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreHoneywell to provide Emirates with wheels, brakes for A380 aircraft fleet

Ten-year agreement for wheels, carbon/carbon brakes will extend overall use life.

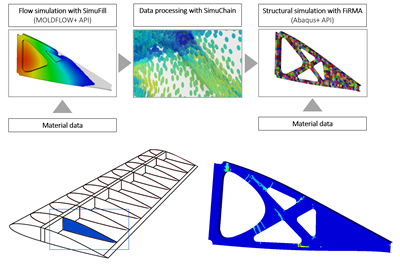

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

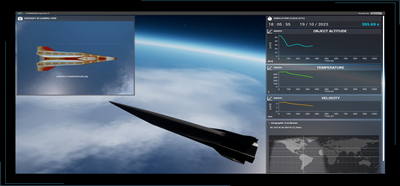

WatchNominal Systems digital twin prototype to progress Hypersonix Dart AE aircraft

One-to-one virtual simulation will enable Hypersonix to capture real flight data of its hypersonic vehicle during maiden flights prior to production.

Read MoreAerospace Xelerated startup program announces year-round model

Unlike its previous model of annual cohorts, the Boeing-led accelerator program will scout, select and match startups throughout the year for the development of scalable, sustainable solutions for aerospace.

Read MoreGKN enhances aeroengine agreement with GE Aerospace

Extended deal sees new tech development and implementation for the GEnx, increased engine fan case supply and GKN’s addition to the repair network.

Read MoreAirbus reports widebody market recovery, production ramp-up progress

Nine-month 2023 earnings detail a 12% increase in consolidated revenue from 2022, meeting 2023 delivery targets and increased production rates for Airbus A350 widebody aircraft.

Read More