Nominal Systems digital twin prototype to progress Hypersonix Dart AE aircraft

One-to-one virtual simulation will enable Hypersonix to capture real flight data of its hypersonic vehicle during maiden flights prior to production.

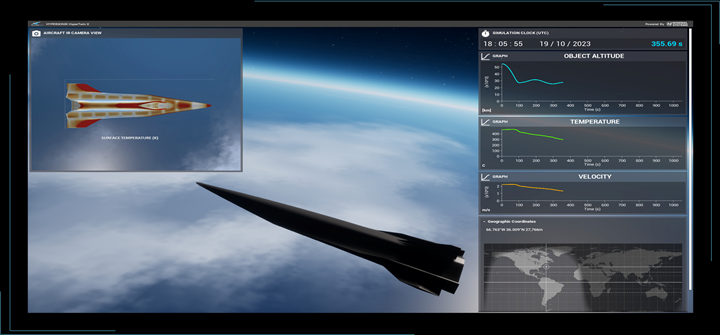

Hypersonix Launch Systems (Brisbane, Australia), at the forefront of hypersonic unmanned aerial systems, has signed a Memorandum of Understanding (MOU) with Nominal Systems (Canberra, ACT, Australia), the next-generation digital twinning platform, to develop Hyper Twin X, a digital twin concept demonstrator of Hypersonix’s Dart AE. The vehicle is set to launch in 2024 and has gained attention by U.S. defense players such as the Defense Innovation Unit and Kratos Defense.

Dart AE is a 3.5-meter-long hypersonic aircraft that is powered by a single Spartan scramjet engine manufactured in high-temperature ceramic matrix composite (HTCMC) and makes significant use of 3D-printed high-temperature metal alloys. It uses hydrogen fuel and will fly at Mach 7 (read more “Hypersonix receives CMC scramjet manufacturing demonstrator”).

“Hypersonic flight is an extremely hostile environment and simulating the physics at these speeds is a complex but important aspect of mission success,” Andy Mulholland, head of product at Hypersonix, explains. “We have built a unique, high-performance simulation capability and we’ll be capturing lots of flight data once Dart AE takes to the sky. Combining these things into a hypersonic digital twin will allow us to fly Dart AE virtually, see the impacts of mission concept changes and allow customers to train hypersonic detect and intercept systems.”

Hypersonix notes that current hypersonic flight programs take a long time and are costly and there’s no guarantee of flight success. A hypersonic digital twin, however, opens the possibility of endless virtual flight tests to prove out missions before the real flight vehicle is built.

A digital twin is a 1:1 virtual representation of a real-world asset — geometry, performance, behavior and condition. Hypersonix and Nominal Systems are not just building a digital twin of the flyer, but also of the atmospheric environment that it operates in. Combined with flight data to be collected during Dart AE’s maiden flight in 2024, the collaboration will enable the next generation of hypersonic technology development.

“The learning and data we gain from the flight of Dart AE will be a game changer for the development of our future product portfolio including VISR and Delta-Velos Orbiter, but also for our clients to use,” Michael Smart, CTO and head of engineering at Hypersonix, says.

For related information, read “A new era for ceramic matrix composites.”

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Next-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.